Impregnation For Cast Aluminum

👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

Vacuum Impregnation of Die Cast Aluminum Housing for a Pump Manufacturer

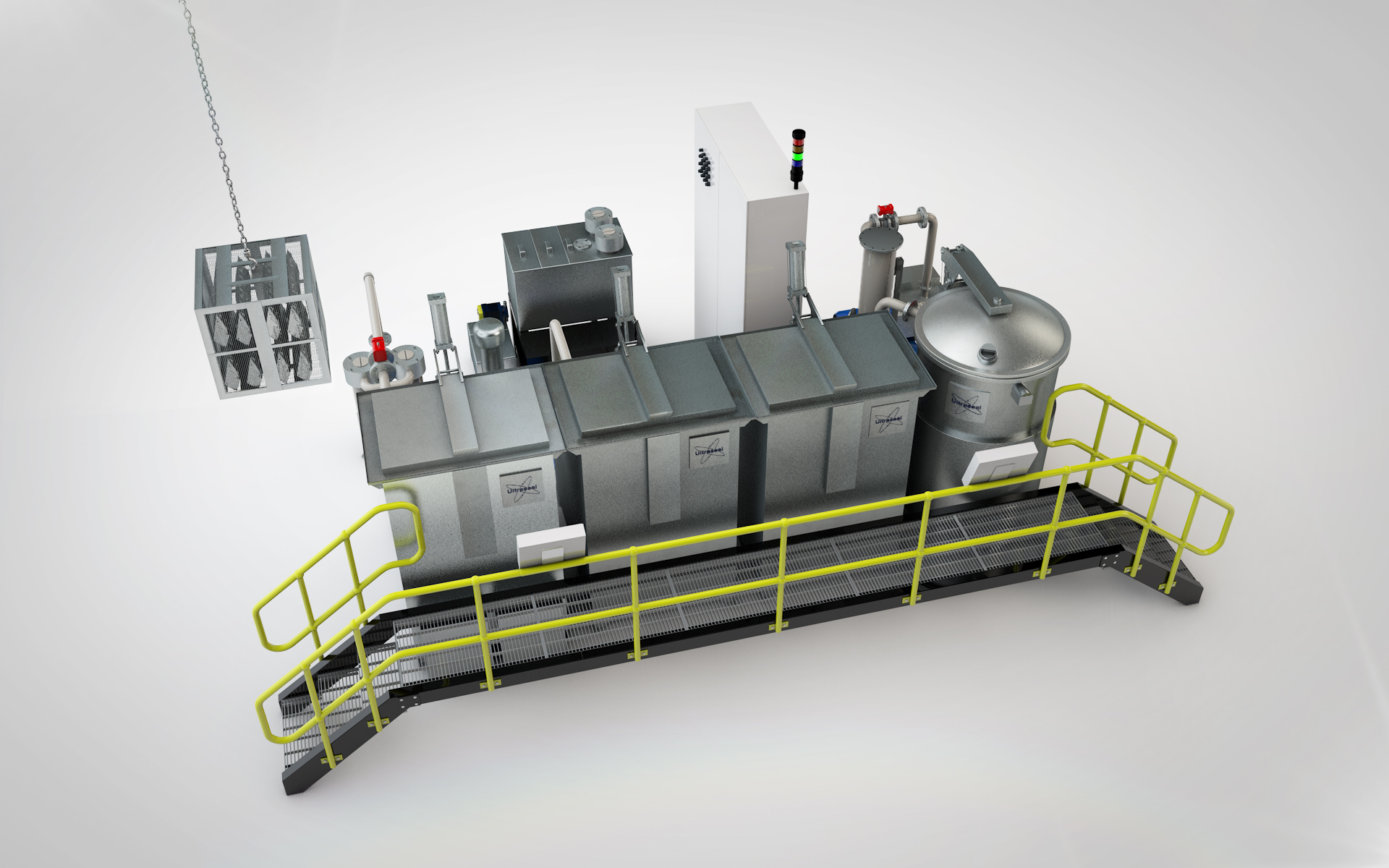

A high volume pump manufacturer required vacuum impregnation of a 380 aluminum, die cast pump. The vacuum impregnation was to provide sealing of micro porosity, and was to be completed after painting and machining, this uncommon order of process required special handling. Custom dividers had to be installed in the vessel to avoid damaging any of the finished surfaces, and meet the high rate of production required.

The process which had explicit porosity impregnation requirements was to be performed on specific areas which required an air tight seal on the pump and oil side of the casting. Each finished part was placed through thermal curing and UV inspection before being placed in specific customer specified packaging. The customer order for this product consisted of 125,000 parts to be produced annually, or 500 per day. We not only met all of the customers’ requirements for quality and production but also provided them with next day delivery to keep their operation stocked at all times.

To learn more about this project, see the table below or contact us directly.

Vacuum Impregnation Capabilities Applied/Processes

Primary:

Vacuum Impregnation

Cast

Trim

wheelabrate

Paint

Machine

Vacuum Impregnation

Secondary:

Thermal Curing

Packaging

Cell Pack in Returnable Cell Divided Packaging Free of Debris and Any Containments

Length: 8.86"

Width: 5.33"

Thickness: 1.34"

Air tightness of pump side/Air tightness of oil seal side

Surface Must Be Sealed to Air Tightness Per Print on Oil and Airside

Parts are Painted Prior to Vacuum Impregnation

In process testing/inspection performed

125,000 Pieces Per Year

500 Pieces Per Day

RoHS/EELV Compliant

MIL-STD-276A

MIL-STD-17563C

ISO 9001:2015

Ace Anodizing & Impregnating Inc.

Address:

4161 Butterfield Road

Hillside IL 60162

Contact:

Phone: 708-547-6680

Fax: 708-547-6682

Email Us

ISO 9001-2015 Registered

AAMA 2603 & 2604 Certified

Mil-DTL-5541F

Mil-8625F Type II Class 1 and 2

Mil-8625F Type III (Hard Coat) Class 1 and 2

Mil-I7563

Mil-STD-276A

AAMA 611 Classes 1 and 2

Copyright 2016 Ace Anodizing & Impregnating, Inc. | All Rights Reserved

Let us know how we're doing. Take Our Customer Surveyno thanks

NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China

Please fill in the form below and our professionals will contact you within 12 hours! For a more prompt reply, you may reach us by phone call or WhatsApp: +86 136 9425 7500.

In the automotive industry,some automotive aluminum parts are made of zinc and aluminum alloys die casting. The effects of impurities in the alloy, that the tooling and equipment may cause the internal defects of the casting. Some defects such as porosity, shrinkage holes, and loose tissues are difficult to detect with the naked eye. The existence of the defects will lead to the risk of leakage of the sealed performance and increase the wear of machining tools, and at the same time add extra production costs. The increase makes it difficult to guarantee product quality. To solve the problem of die casting high rejection rate, the "impregnation" process is adopted for remedy.

Therefore, impregnation technology has been very mature since the 1970s. The application rate of this technology has reached 95%. The impregnation can be infiltrated with the small shrinkage holes and air holes in the casting to enhance the compactness of the die casting parts.

To meet our customer requirement and improve the die casting parts’quality, EMP Die Casting can provide the impregnation services, leakage testing of aluminum casting, also we could offer FREE Technical Analysis on the die casting parts design, if you might require this, we are glad to support your projects at anytime.

In recent years, with the frequent occurrence of automotive market price wars, cost pressures have continued to affect the supplier, causing many automotive parts manufacturer to face huge challenges ...

Die casting mold is important to process equipment in die casting production. The molten metal is cooled and solidified in a die casting mold to form a die casting. The shape, size, quality, and smoot...

The "fuel tank" of new energy vehicles-batteries: the battery is one of the main parts of electric vehicles, and the function of the battery is the only source of power for the vehicle's...

An IATF16949 Certified Precision Die Casting Aluminum Parts Manufacturer Since 1993

NO.38 Duanzhou 3rd Road, Zhaoqing(526060), Guangdong, China

Copyright© EMP Tech Co.,Ltd. All Rights Reserved.

Big Ass Teacher Milf

Lesbian Hentai Tit

Best Tube Clips Teen Young

Www Girls Want Fuck Com

Russian Mature Photo Gallery

Impregnation for aluminum casting and brass casting ...

Why Aluminum Die Casting Parts need to be Impregnated ...

impregnation of aluminum casting - Spacecraft engineering ...

How Impregnation Makes Porous Castings Pressure Tight

Vacuum Impregnation of Automotive Casting Parts - Henke…

Impregnation | Haworth Castings | UK Aluminium Sand ...

Cast alloy based on aluminium to produce by impregnation ...

What is Casting Impregnation? - Definition from Corrosionpedia

Impregnation For Cast Aluminum

)

)

)