How to build DIY electric surf | Anti-instruction

Georgy Zenker"How does this surf with an electric motor cost 10 000 euro?

I'll do it with my dad in the garage for 1 000"

If, after this thought, you began to search for information on the Internet and came across this article - open a beer / tip a stack / pour a glass of white, and let's go.

What an electric surf consists of:

- propeller / jetpump

- electric motor

- power controller (ESC)

- battery

- hull

1. Propeller / jetpump

The principle of their operation is completely different: the propeller, like a screw, is screwed into the water and thereby pushes the vessel forward, and the jet pump is essentially a jet engine (creates a stream, the reaction force from which sets the ship in motion).

In the case of an electric surfer, the use of a propeller is possible, but this design will look extremely ridiculous, so only a jet pump remains.

The question of buying a water cannon leads us to Aliexpress (or you can buy from me), where caring Chinese engineers posted many samples of their products.

"And which one to choose, you ask," - finishing the bottle of beer. This is a very good question, because the jet pump is the main point, and other components will hang from it along the chain.

It so happened (in practice) that a jet pump with a diameter of about 90-120 mm is enough to push you through space. If there is a choice in terms of price, then it’s like with a choice of wine - you don’t have to take the cheapest, something in the middle is better.

After paying for the order, reward yourself with the opening of the second bottle of beer. And today it’s better not to buy anything, but just read the following paragraphs and return to the question tomorrow.

To enter the gliding (sliding on the surface of the water, with minimal resistance), you will need 50 kg of thrust.

For a water jet with a diameter of 90 mm, about 6400 rpm is needed to create such thrust.

Now we need to understand the torque characteristic of the purchased jet pump (because in 99% the manufacturer will not provide it).

In a simple case: a 90 mm water jet at 6400 rpm will require about 10 Nm.

If you want to delve into the topic: then open the calculator and try to select the geometric parameters of the purchased jet pump using the selection method. As soon as the parameters are selected, the jet pump torque characteristic will become known

There will be a lot of graphs and simple math to follow - so prepare the 3rd bottle.

Jet pump price: 300-1000 euro

2. Electric motor

To rotate the jet pump at 6400 rpm, you need an electric motor. We will only talk about brushless DC motors (BLDC), others do not use in this area. For such motors, there is a characteristic KV (revolution per volt).

Those. if our engine has 200 kV, then when 1 volt of voltage is applied to it, it will rotate at a speed of 200 rpm.

For water transport, you should not exceed 60 volts (it is life-threatening and almost all European manufacturers fit into this framework), so a motor with a characteristic of 200 kV will produce about 12,000 rpm at 60 volts without load.

Under load, the speed will definitely be less - on average, the drawdown will be 15-30%.

It is also worth considering that a discharged battery has a much lower voltage (45 volts), then we must proceed from the worst case:

200 * 45 * 0.7 = 6300 rpm. Those. +/- in the worst case, the motor will give the desired speed in any case.

There is also such a characteristic as a torque - and it is better to ask the manufacturer for it. In any case, today we realized that with a battery of 45-60 volts, a motor of 200 kV is enough for us.

Well, well, the motor has a lot of other characteristics, what's next? Next, you need to find out the diameter of the electric motor and its type (inrunner and outrunner).

Inrunner - a classic type of electric motor, the shaft (rotor) rotates inside the housing (stator).

Outrunner - the central part (stator) stands still and the outer part (rotor) rotates. This design is more complicated, but the engine torque is greater.

It is preferable to use an outrunner to drive a water jet. The outer diameter of the electric motor must be 20% larger than the diameter of the jet pump

Those you have a jet pump diameter of 90 mm, which means that the diameter of the electric motor will be 90 * 1.2 = 108 mm.

Here, according to these two data (200 kV and a diameter of 108 mm), we will look for an electric motor. When the desired option is found, it is necessary to ask the manufacturer for a torque characteristic (graph).

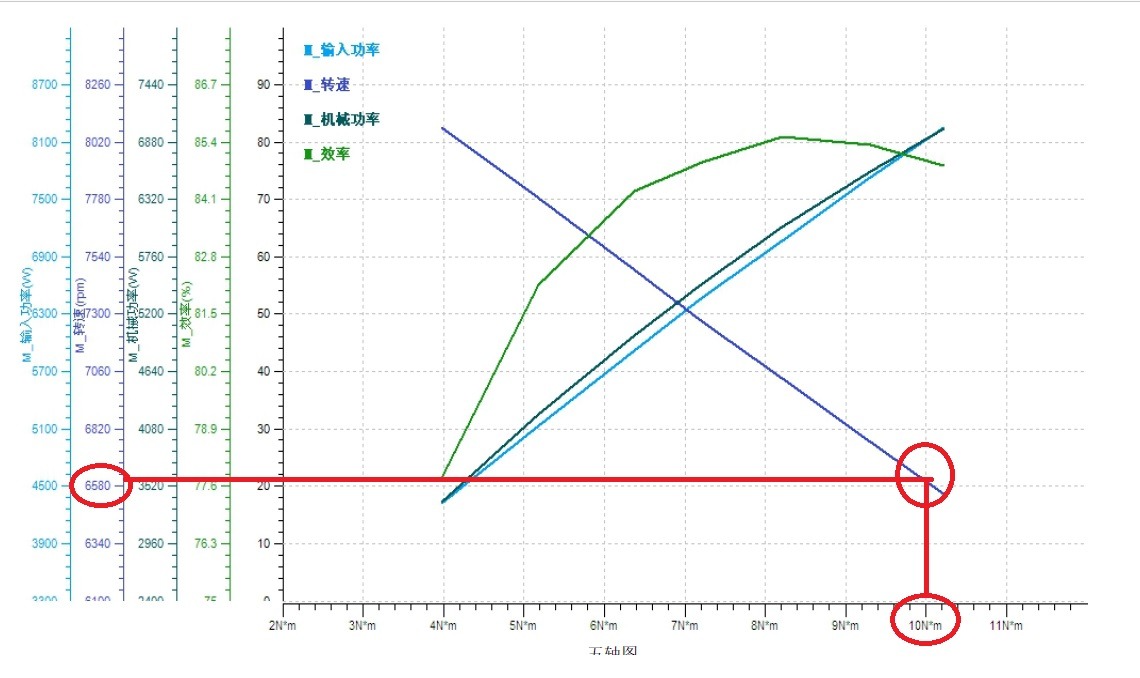

Next, you will need to superimpose the graph of the water jet (or the 10Nm point) and the graph of the electric motor.

At their intersection point, the electric motor will operate in a stable temperature mode, everything further (higher in speed) will heat the electric motor. Naturally, this is an ideal case and in fact, this point will be closer to the origin.

Next, you need to take care of buying a power controller. Simple math (6400 rpm at 10 Nm) gives us 6.7 kW of power.

Electric motor price: from 500 euro

3. Power controller (ECS)

If we remember that our battery has a voltage of 45-60 volts, then it is easy to calculate the current strength in the worst case (when the battery is discharged).

6700/45 = 148.88 ampers, this is how much the controller must keep in constant mode.

So as not to burn the MOSFETs time of the first start under load, as well as to comply with cooling requirements, the controller must be taken with a service factor of at least 1.3 Those. for 148.88 A, you need to take a controller with a continuous current of 200-220 A (minimum)

My personal opinion: VESC-based controllers do not hold the declared load and cannot cope with reverse current surges (no protection), so it's better not to use them, and look for something industrial controllers (naturally they will be more expensive).

Controller price: from 400 euro

4. Battery

The most dangerous element. It all depends on the budget and your wishes for capacity.

The main thing is that the battery would hold the maximum current (148.88 A), have a BMS (cell balancing) and a connection system (power relay). And it is definitely better to entrust the assembly of the battery to professionals because any mistakes can cost you life.

Li-Ion 18650 (or 21700) cells have the best ratio in terms of capacity/mass ratio, they are also quite safe. In this case, to obtain a voltage of 45-60 volts, you will need an assembly of 14 cells (in series).

Now we need to calculate the required capacity: let's take an average current of 100A and assume that the power reserve will be 30 minutes (0.5 hours) - i.e. 100 * 0.5 = 50 Ah. Because battery capacity is obtained from the parallel connection of cells - the total capacity (50 Ah) must be divided by the capacity of each cell (for example 2.5 Ah) = 50 / 2.5 = 20.

It would be nice to check that the elements will hold such a load and do not overheat, so the maximum current (148.88A) is divided by the number of parallel connected elements (20) = 148.88 / 20 = 7.44 A per cell.

Under these parameters, Samsung 30Q is suitable (15A discharge current and 3 Ah capacity) - i.e. the total battery capacity will be slightly more than 20 * 3 = 60 Ah.

In total, we get the configuration: 14S20P - i.e. the number of elements will be equal to 280 pcs (14 * 20)

Battery price: from 1500 euro (only for cells without assembly, BMS, relay)

5. Hull

Here you can give one piece of advice - you need to buy a donor, which will have to be worked out for a long time and hard. In any case, it will be much cheaper and easier than building it yourself from scratch.

Maximum attention should be paid to the modularity of the design - because. small volumes are easier to isolate from water.

And to isolate from water, you need everything and as reliably as possible, and wherever you can use caoutchouc compounds

Housing price: from 500 euro (used jet surf hull as an example)

Summary: At least 3200 euro. You will only need to spend on basic components.

Given that all the little things, by the time it enters the water, the board will cost 4500 euro.

And this is just the beginning of a journey called "test operation": the batteries will be filled with water, the motors will burn, and t in the best case, on the 3rd assembled prototype, it will be possible to somehow move stably.

Actually, it turns out a 10 000 euro.