How Different Production Processes Affect the Residences of Elastic Bands

Elastic bands, an usual yet necessary product in various sectors, are affected considerably by their manufacturing procedures. The properties of these bands, such as elasticity, strength, durability, and strength, are largely figured out by just how they are made. Attracting from the top search results page on Google, this short article discovers the influence of various manufacturing procedures on the properties of elastic bands.

1. Product Choice

Natural vs. Artificial Rubber: The option between all-natural and artificial rubber is a fundamental choice in the production process. Natural rubber provides superior flexibility and flexibility, while artificial variations provide enhanced toughness and resistance to environmental variables like UV light and chemicals.

2. Vulcanization Refine

Vulcanization Method: This procedure involves including sulfur to rubber to improve its homes. The level and approach of vulcanization considerably impact the flexibility, tensile toughness, and thermal security of the rubber bands.

Temperature and Time: The temperature level and duration of the vulcanization procedure also play a vital role. Greater temperatures or longer vulcanization times can result in bands that are a lot more rigid and less elastic.

3. Extrusion and Molding

Extrusion Process: In this technique, rubber is required via a die to produce long tubes or strips, which are then cut into bands. The stress and rate of extrusion can influence the band's density and flexibility.

Molding Methods: Molding procedures, such as shot or compression molding, are utilized for developing bands with particular shapes or accounts. The pressure and warm applied throughout molding can influence the band's last buildings.

4. Mixing and Intensifying

Rubber Compounding: The process of blending rubber with other products (like fillers, plasticizers, and anti-oxidants) can considerably change the buildings of the rubber bands. For example, adding plasticizers can enhance flexibility, while fillers can improve strength and durability.

5. https://www.amdwebbing.com -Processing Treatments

Warm Therapy: Post-processing warm therapies can even more customize the residential properties of rubber bands. As an example, annealing (a process of heating and afterwards slowly cooling down) can soothe interior tensions, improving elasticity and minimizing brittleness.

Surface Therapies: Coatings or surface treatments can be put on boost the band's grasp, resistance to wear, or aesthetic appeal.

6. Quality Assurance and Screening

Consistency in Manufacturing: Maintaining consistency in the manufacturing process is crucial for making sure consistent buildings across all elastic bands produced.

Examining for Characteristic: Extensive testing for buildings like tensile strength, elongation, and durability makes certain that the bands fulfill the required specifications and performance standards.

7. Environmental and Aging Factors

Aging Refine: In time, the residential or commercial properties of elastic bands can change due to ecological aspects like oxygen, ozone, and UV light. The production process can include additives to slow down this aging process and keep the band's residential or commercial properties for longer.

8. Customization for Specific Applications

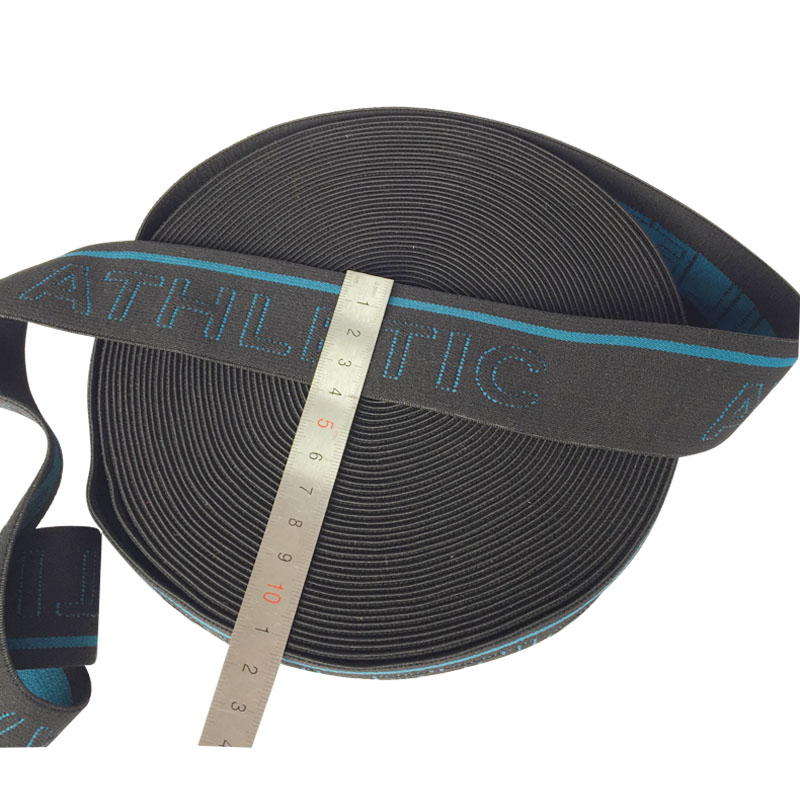

Customizing Residences: The production process can be customized to create bands with particular properties for specific applications, such as medical-grade bands, sturdy industrial bands, or bands for fashion devices.

Final thought

The manufacturing processes of elastic bands considerably influence their physical and mechanical homes. Recognizing these procedures and their effect is essential for producers to produce bands that satisfy specific demands and for customers to choose the ideal sort of band for their requirements. From the choice of material to the final quality control, each step in the production process plays an essential role in defining the features of the rubber bands, ensuring they perform properly in their intended applications.