Hole Size

💣 👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

The exact diameter of a golf hole is 4.25 inches or 108 millimeters, and it is universal throughout the whole world. If you have clicked on this article, we believe you would like to know more about the history of the golf hole and to know the exact reason behind the exact dimension of the hole.

lumensports.com/how-wide-is-a-golf-h…

www.tanoi-mfg.co.jp/us/technical/holesize_c/m.html

Перевести · Строк: 73 · Nominal size: Pitch: Percentage of thread engagement hole diameter (mm) Minor dia of internal thread: 100%: 90%: 80%: 70%: M16: 2: …

https://blog.draftsperson.net/holes-and-slots-standard-sizes

Перевести · 10.03.2021 · Holes and Slots Standard Holes. Standard hole sizes for bolts are made 1/16-in. larger in diameter than the nominal size of the fastener...

https://www.stanleyengineeredfastening.com/-/media/web/sef/resources/docs/spiralock/...

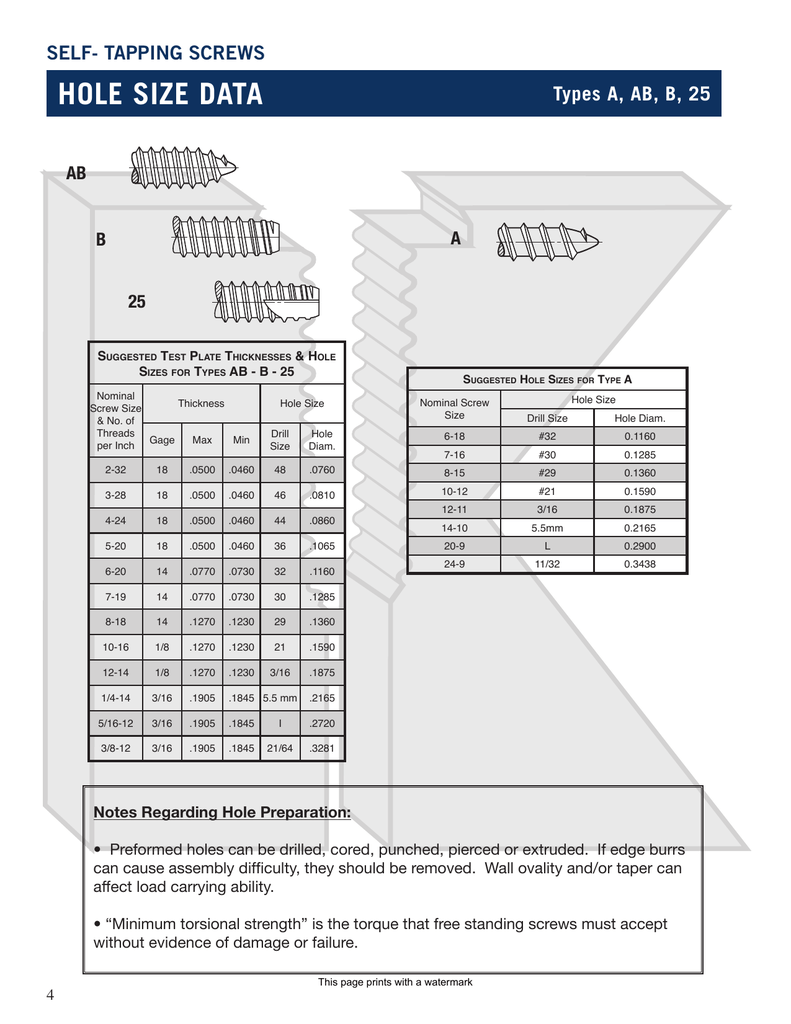

• For harder materials, a hole minor diameter near the high end of the suggested range is recommended. • Spiralock threaded holes require the use a larger minor diameter than conventional threads. English/ Fractional Thread Size Hole Minor Diameter Min. (in) Hole Minor Diameter Max. (in) Suggested Drill Size* 0 – 80 0.052 0.054 #55

https://amesweb.info/Screws/Clearance-Hole-Chart.aspx

Перевести · Строк: 32 · Nominal Screw Size: Fit Class - Normal: Fit Class - Close: Fit Class - Loose: Nominal Drill Size: Hole Diameter: Nominal Drill Size: Hole Diameter: Nominal Drill Size: Hole …

How to Determine the hole size for an Internal Thread -- SHOP GEM !!

Choosing Pilot Hole Size for Wood Screws

Maximize Hole Size Cornhole Tips and Tricks

Hole size too large? Here is how to fix it.

https://threadingtoolsguide.com/en/core-hole-dimensions-the-tables

Перевести · Строк: 195 · Core hole dimensions for metric thread DIN 13 The metric ISO thread or standard thread is measured in millimetres and is the most commonly used in Europe. Nominal size mm: Pitch mm: Core hole …

https://amesweb.info/Screws/Metric-Clearance-Hole-Chart.aspx

Перевести · Nominal Drill Size: Hole Diameter: Nominal Drill Size: Hole Diameter: Nominal Drill Size: Hole Diameter: Min. Max. Min. Max. Min. Max. M56: 62: 62: 62.46: 58: 58: 58.3: 66: 66: …

https://m.youtube.com/watch?v=iAH31jh94EA

Перевести · 20.10.2016 · Here is how to fix it. - YouTube. If playback doesn't begin shortly, try …

https://en.m.wikipedia.org/wiki/List_of_drill_and_tap_sizes

Ориентировочное время чтения: 5 мин

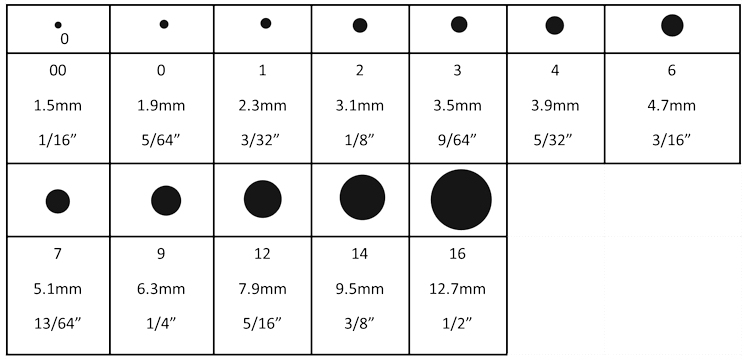

Below is a comprehensive drill and tap size chart for all drills and taps, imperial and metric, up to 36.5 millimetres (1.44 in) in diameter.

In manufactured parts, holes with female screw threads are often needed; they accept male screws to facilitate the building and fastening of a finished assembly. One of the most common ways to produce such threaded holes is to drill a hole of appropriate size with a drill bit and then tapit with …

Below is a comprehensive drill and tap size chart for all drills and taps, imperial and metric, up to 36.5 millimetres (1.44 in) in diameter.

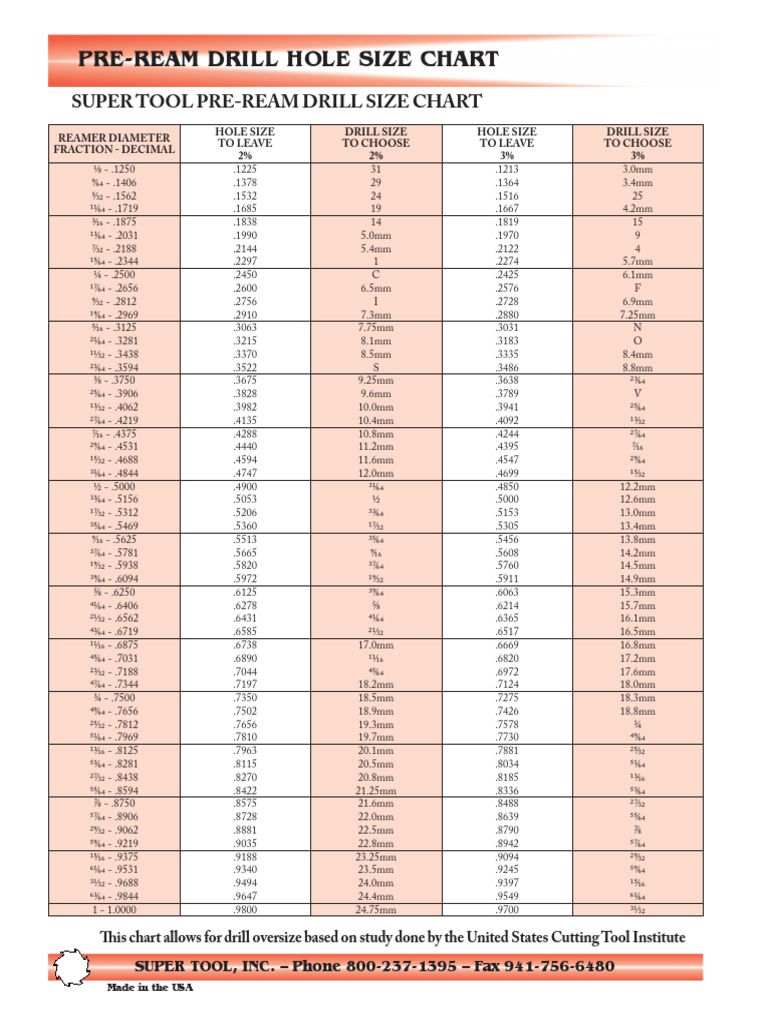

In manufactured parts, holes with female screw threads are often needed; they accept male screws to facilitate the building and fastening of a finished assembly. One of the most common ways to produce such threaded holes is to drill a hole of appropriate size with a drill bit and then tap it with a tap. Each standard size of female screw thread has one or several corresponding drill bit sizes that are within the range of appropriate size—slightly larger than the minor diameter of the mating male thread, but smaller than its pitch and major diameters. Such an appropriately sized drill is called a tap drill for that size of thread, because it is a correct drill to be followed by the tap. Many thread sizes have several possible tap drills, because they yield threads of varying thread depth between 50% and 100%. Usually thread depths of 60% to 75% are desired.

People frequently use a chart such as this to determine the proper tap drill for a certain thread size or the proper tap for an existing hole.

Не удается получить доступ к вашему текущему расположению. Для получения лучших результатов предоставьте Bing доступ к данным о расположении или введите расположение.

Не удается получить доступ к расположению вашего устройства. Для получения лучших результатов введите расположение.

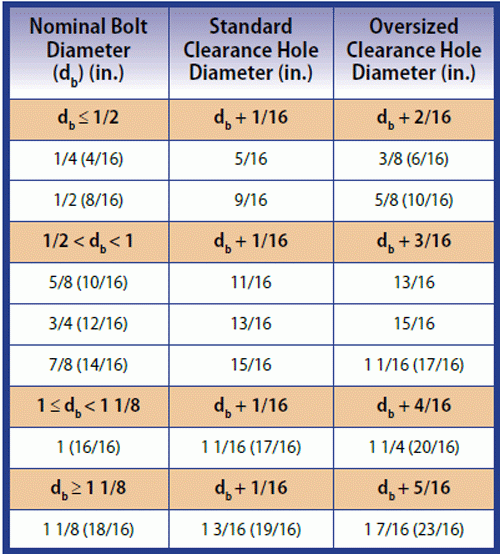

This information applies to the American Steel Industry.

Standard hole sizes for bolts are made 1/16-in. larger in diameter than the nominal size of the fastener body. This provides a certain amount of play in the holes, which compensates for small misalignment’s in hole location or assembly, and aids in the shop and field entry of fasteners. In the absence of approval by the engineer for use of other hole types, standard holes shall be used in high strength bolted connections.

Although most holes for high-strength bolts are made 1/16-in. larger in diameter than the bolt body, certain conditions encountered in field erection require greater adjustment than this clearance can provide and approval from the engineer is required.

The maximum sizes of holes for bolts are given in the table below, except that larger holes, required for tolerance on location of anchor bolts in concrete foundations, are permitted in column base details.

Standard holes shall be provided in member-to-member connections, unless oversized, short-slotted or long-slotted holes in bolted connections are approved by the designer. Finger shims up to 1/4-in. may be introduced into slip-critical connections designed on the basis of standard holes without reducing the allowable shear stress of the fastener.

When approved by the engineer, oversize, short slotted holes or long slotted holes may be used subject to the following joint detail requirements:

(1) Oversize holes may be used in any or all plies of connections in which the allowable slip resistance of the connection is greater than the applied load. Oversized holes shall not be used in bearing-type connections. Hardened washers shall be installed over oversized holes in an outer ply.

(2) Short slotted holes may be used in any or all plies of connections designed on the basis of allowable stress on the fasteners provided the load is applied approximately normal (between 80 and 100 degrees) to the axis of the slot. Short slotted holes may be used without regard for the direction of applied load in any or all plies of connections in which the allowable slip resistance is greater than the applied force. Washers shall be installed over short-slotted holes in an outer ply; when high strength bolts are used, such washers shall be hardened.

(3) Long slotted holes may be used in one of the connected parts at any individual faying surface in connections designed on the basis of allowable stress on the fasteners provided the load is applied approximately normal (between 80 and 100 degrees) to the axis of the slot. Long slotted holes may be used in one of the connected parts at any individual faying surface without regard for the direction of applied load on connections in which the allowable slip resistance is greater than the applied force. Where long-slotted holes are used in an outer ply, plate washers or a continuous bar with standard holes, having a size sufficient to completely cover the slot after installation, shall be provided. In high-strength bolted connections, such plate washers or continuous bars shall not be less than 5/16-in. thick and shall be of structural grade material, but not be hardened. If hardened washers are required for use of high-strength bolts, the hardened washers shall be placed over the outer surface of the plate washer or bar.

(4) Fully inserted finger shims between the faying surfaces of load transmitting elements of connections are not to be considered a long slot element of a connection.

Hole Dimensions – Short Slot

(Width x Length)

Hole Dimensions – Long Slot

(Width x Length)

Hole sizes for steel-to-steel structural connections are not the same as hole sizes for steel-to-concrete anchorage applications. In the case of steel-to-steel connections, the parts are made in a shop under good quality control, so standard holes (bolt diameter plus 1/16″), oversized holes (bolt diameter plus 3/16″), and short and long-slotted holes can be used quite successfully. However, the field placement of anchorage devices has long been subject to more permissive tolerances (and often, inaccuracies that exceed those tolerances anyway and may require consideration by the structural Engineer of Record).

AISC published Steel Design Guide Series 1, Column Base Plates back in the early 1990s. At that time, it was recognized that the quality of foundation work was getting worse and worse. To allow the erector (and designer) greater latitude when possible, the permissible hole sizes in base plates were increased. These same larger hole sizes were included in the 2nd ed. LRFD Manual. The values there are maximums, not a required size. Smaller holes can be used if desired. Plate washers are generally required with these holes because ASTM F436 washers can collapse into the larger-sized holes, even under erection loads.

The larger hole sizes are primarily intended for the majority of base plates that transfer only axial compression from the column into the foundation. The anchor rods don’t usually do much after erection in that case.

To allow for misplaced bolts, holes in base plates are oversized. The AISC Manual of Steel Construction recommends the following oversized hole diameters for each bolt diameter:

AISC, Steel Design Guide Series 1, Column Base Plates, suggests that using oversize holes meeting these criteria may still not accommodate field variations in anchor bolt placement and suggests adding 1/4 in. to the hole diameter listed. The guide recommends using a heavy plate washer over the holes. The AISC Structural Steel Educational Council cites the following example: “If bolts are misplaced up to 1/2 inch, the oversized base plate holes normally allow the base plate and column to be placed near or on the column line. If the bolts are misplaced by more than 1/2 inch, then corrective work is required.”

Based on AISC oversize holes, the AISC Structural Steel Educational Council recommendations, and concrete contractor anchor-bolt placement techniques, ASCC (American Society of Concrete Contractors) concrete contractors recommend the following tolerance for each bolt location:

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Provided for free with no warranty · Log in

Cas Feet Up Boots Heels Slider

Hard Brutal Bdsm Porn Cry

Comfortable Heels

Christina High Heels Boots

Play Free Porn Game

Hole size for general Metric Threads

Holes and Slots, Standard Sizes - Draftsperson.net

Hole Sizes for Cut Tapping - STANLEY® Engineered Fastening

CLEARANCE HOLE CHART - Amesweb

Core hole dimensions - The tables - Threading tools guide ...

Metric Clearance Hole Chart - AMES

List of drill and tap sizes - Wikipedia

Hole Size