Hole Making

💣 👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

Contents

1. Machined holes 2. Hole-making operations

About CustomPartNet

About Us

Contact Us

Privacy Policy

List Your Company

Advertise

Process Overviews

Injection Molding

Sand Casting

Milling

Die Casting

Glossary

Copyright © 2021 CustomPartNet. All Rights Reserved.

Hole-making is a class of machining

operations that are specifically used to cut a hole into

a workpiece .

Machining, a material removal process,

creates features on a part by cutting away the unwanted

material and requires a machine, workpiece,

fixture , and

cutting tool. Hole-making can be performed on a variety

of machines, including general machining equipment such

as CNC milling machines or CNC turning machines.

Specialized equipment also exists for hole-making, such

as drill presses or tapping machines. The workpiece is a

piece of pre-shaped material that is secured to the

fixture, which itself is attached to a platform inside

the machine. The cutting tool is a cylindrical tool with

sharp teeth that is secured inside a piece called a

collet, which is then attached to the spindle, which

rotates the tool at high speeds. By feeding the rotating

tool into the workpiece, material is cut away in the

form of small chips to create the desired feature.

Hole-making operations are

typically performed amongst many other operations in the

machining of a part. However, hole-making may be

performed as a secondary machining process for an

existing part, such as a casting or forging. This can be

done to add features that were too costly to form during

the primary process or to improve the tolerance or

surface finish of existing holes.

In machining, a hole is a

cylindrical feature that is cut from the

workpiece by a

rotating cutting tool that enters the workpiece axially.

The hole will have the same diameter of the cutting tool

and match the geometry (which may include a pointed

end). Non-cylindrical features, or pockets, can also be

machined, but they require end milling

operations not hole-making operations. While all machined holes have

the same basic form they can still differ in many ways

to best suit a given application. A machined hole can be

characterized by several different parameters or

features which will determine the hole-making operation

and tool that is required.

Several hole-making operations exist, each using a different type of cutting tool and forming a different type of hole.

Drilling

- A drill bit enters the workpiece axially and

cuts a blind hole or a through hole with a

diameter equal to that of the tool. A drill

bit is a multi-point tool and typically has

a pointed end. A twist drill is the most

commonly used, but other types of drill

bits, such as a center drill, spot drill, or

tap drill can be used to start a hole that

will be completed by another operation

Reaming

- A reamer enters the workpiece axially and

enlarges an existing hole to the diameter of

the tool. A reamer is a multi-point tool

that has many flutes, which may be straight

or in a helix. Reaming removes a minimal

amount of material and is often performed

after drilling to obtain both a more

accurate diameter and a smoother internal

finish.

Tapping

- A tap enters the workpiece axially and cuts

internal threads into an existing hole. The

existing hole is typically drilled by the

required tap drill size that will

accommodate the desired tap. The tap is

selected based on the major diameter and

pitch of the threaded hole. Threads may be

cut to a specified depth inside the hole

(bottom tap) or the complete depth of a

through hole (through tap).

Boring

- A boring tool enters the workpiece axially

and cuts along the internal surface of an

existing hole to enlarge the diameter or

obtain more precise dimensions. The boring

tool is a single-point cutting tool, which

can be set to cut the desired diameter by

using an adjustable boring head.

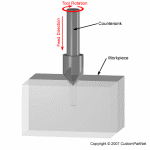

Counterboring

- A counterbore tool enters the workpiece

axially and enlarges the top portion of an

existing hole to the diameter of the tool.

Counterboring is often performed after

drilling to provide space for the head of a

fastener, such as a bolt, to sit flush with

the workpiece surface. The counterboring

tool has a pilot on the end to guide it

straight into the existing hole.

Countersinking

- A countersink tool enters the workpiece

axially and enlarges the top portion of an

existing hole to a cone-shaped opening.

Countersinking is often performed after

drilling to provide space for the head of a

fastener, such as a screw, to sit flush with

the workpiece surface. Common included

angles for a countersink include 60, 82, 90,

100, 118, and 120 degrees.

https://www.youtube.com/watch?v=_VFyL9dxgrY

http://www.custompartnet.com/wu/hole-making

Nelson Freitas Rebound Chick

Wendy Star Porn Pics

German Metal Companies Pipe

Holemaking - YouTube

Machining Hole-making Process, Opertaions, Tools, …

Making of Holes [2003] - YouTube

42-Introduction to Hole Making - YouTube

Hole making – ISCAR E-LEARNING

Hole-making and Drilling Technology for Composites ...

HOLE MAKING MACHINE - YouTube

Cutting Tool Innovation to Speed Up Metalworking ...

hole-making中文_hole-making是什么意思 - iChaCha

Hole Making