Head Studs vs Bolts: Which Offers Better Strength and Durability?

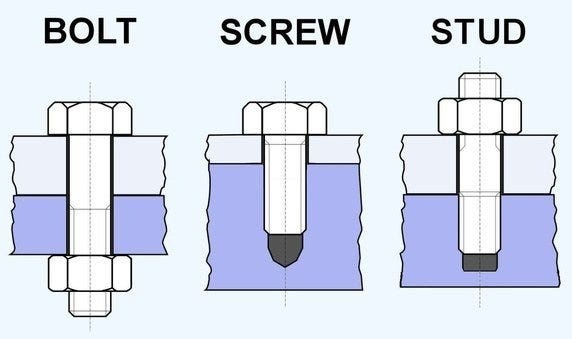

Head Studs vs BoltsIn the world of diesel engine performance, the ongoing debate surrounding head studs versus bolts has captivated both enthusiasts and professionals. Both components play a vital role in securing the cylinder head to the engine block, but the question persists: which option offers superior strength and durability? Let's delve into the intricacies of head studs and bolts, particularly in the context of renowned diesel engines like the Chevy Duramax, and examine their respective merits in enhancing reliability and performance.

Head Studs: Engineered for Unyielding Strength

Head studs, constructed from top-quality materials such as ARP2000 or 8740 chromoly steel, are known for their exceptional tensile strength and resistance to stretching. Unlike traditional bolts, head studs utilize precision-machined nuts and washers for fastening, ensuring uniform clamping force distribution across the cylinder head. This design not only enhances stability but also minimizes the risk of gasket failure under extreme cylinder pressures, thereby bolstering engine reliability.

Advantages of Head Studs:

- Superior Strength: Head studs demonstrate superior tensile strength compared to bolts, making them ideal for enduring the demands of high-performance diesel engines.

- Enhanced Stability: The utilization of nuts and washers promotes even clamping force distribution, reducing the likelihood of uneven pressure points and potential gasket leaks.

- Simplified Installation: Head studs streamline the cylinder head installation process, enabling precise torque application and minimizing the risk of improper tightening.

- Long-Term Reliability: Once correctly installed, head studs necessitate minimal maintenance and offer enduring performance, instilling confidence in engine builders and enthusiasts alike.

Bolts: Traditional and Versatile

Bolts continue to be a popular choice for cylinder head fastening in diesel engines due to their versatility and cost-effectiveness. Typically forged from hardened steel or alloys, bolts thread directly into the engine block and rely on torque specifications for clamping force. Although not inherently weaker than head studs, bolts may be more susceptible to stretching under extreme loads, potentially compromising clamping force and leading to gasket issues over time.

Advantages of Bolts:

- Cost-Efficiency: Bolts are generally more economical than head studs, making them a preferred option for engine builds where budget is a primary concern.

- Versatility: Bolts are available in various sizes and configurations, catering to diverse engine applications and modifications.

- Familiarity: Many mechanics and engine builders are accustomed to working with bolts, making them a convenient and widely accepted choice for cylinder head fastening.

Reliability and Performance Comparison

When assessing head studs vs head bolts in terms of strength and durability, it's crucial to consider the specific demands of the application. While bolts offer versatility and cost-effectiveness, head studs provide unmatched strength and stability, particularly in high-performance diesel engines like the Chevy Duramax. For enthusiasts prioritizing maximum reliability and durability, head studs are often the preferred choice, offering assurance and confidence in the longevity of their engine.

In conclusion, the selection between head studs and bolts hinges on factors such as budget, performance objectives, and application requirements. While bolts may suffice for standard engine builds, head studs offer a superior solution for enthusiasts seeking to extract maximum power and reliability from their diesel engines. By comprehending the nuances of each option and consulting with experienced professionals, enthusiasts can make informed decisions to ensure the longevity and performance of their engines.