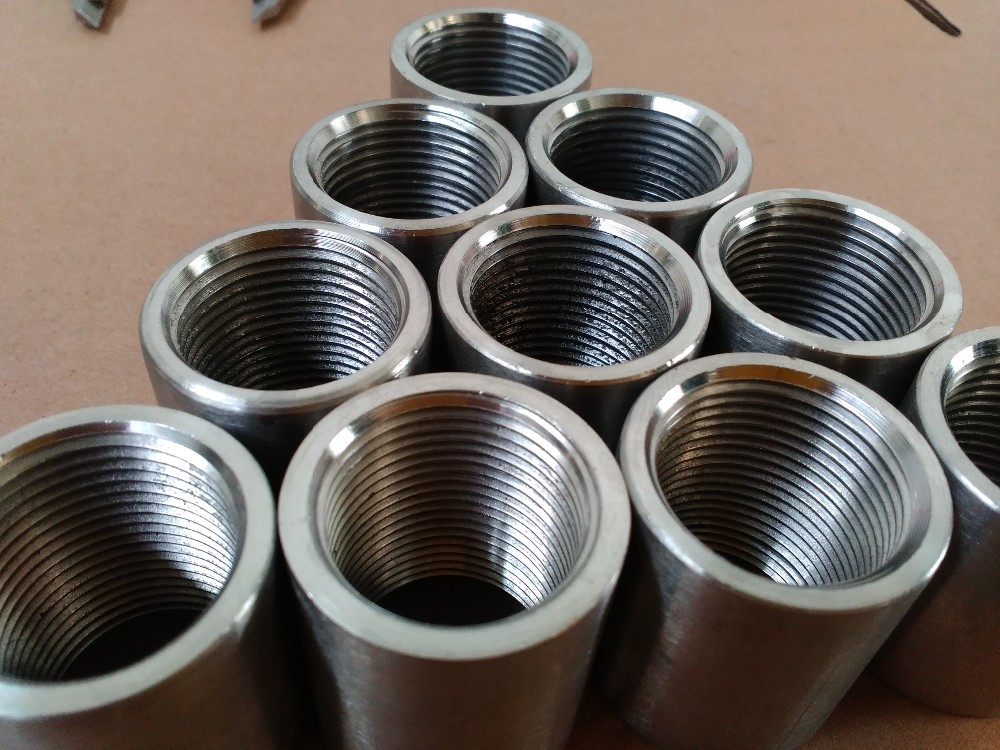

Female Thread

💣 👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

https://encyclopedia2.thefreedictionary.com/female+thread

Перевести · Find out information about female thread. The thread on the inside of a pipe, fitting, or machine screw. McGraw-Hill Dictionary of …

https://www.collinsdictionary.com/dictionary/english/female-thread

Перевести · 15.04.2021 · Female thread definition: a helical groove in a cylindrical hole formed by a tap or lathe tool | Meaning, pronunciation, translations …

https://en.m.wikipedia.org/wiki/Gender_of_connectors_and_fasteners

In plumbing fittings, the "M" or "F" usually comes at the beginning rather than the end of the abbreviated designation. For example:

• MIPT denotes Male Iron Pipe Thread;

• FIPT denotes Female Iron Pipe Thread.

A short length of pipe having an MIP thread at both ends is sometimes called a nipple. A short pipe fitting having an FI…

In plumbing fittings, the "M" or "F" usually comes at the beginning rather than the end of the abbreviated designation. For example:

• MIPT denotes Male Iron Pipe Thread;

• FIPT denotes Female Iron Pipe Thread.

A short length of pipe having an MIP thread at both ends is sometimes called a nipple. A short pipe fitting having an FIP thread at both ends is sometimes called a coupling.

Hermaphroditic connections, which include both male and female elements in a single unit, are used for some specialized tubing fittings, such as Storz fire hose connectors. A picture of such fittings appears in § Genderless (hermaphroditic), below.

https://m.youtube.com/watch?v=cfgFo9ZKm6A

Перевести · 28.02.2017 · In this video MTM Hydro covers male vs. female …

How to Understand Male vs. Female Threading

The Difference Between Male and Female Threads

YouTube › STANLEY Engineered Fastening

cutting ACME threads (male & female)

How To Use Female NPT Quick-test XT Adapters | Ralston Instruments

How To Use NPT Female Quick-test Gauge Adapters | Ralston Instruments

https://m.youtube.com/watch?v=X5YyTZwCNCA

Перевести · 21.01.2019 · The Difference Between Male and Female Threads - YouTube. This video covers the easiest way to remember the difference between a male thread and a female thread…

https://trimantec.com/blogs/t/thread-identification-guide

Перевести · 13.11.2020 · First, you’ll need to identify whether the thread type is male or female. Take a look at where the threads are located. If they’re on the outside of the thread, it’s a male thread. If they’re on the inside of the thread, it’s a female thread. …

Every matched pair of threads, external and internal, can be described as male and female. For example, a screw has male threads, while its matching hole (whether in nut or substrate) has female threads. This property is called gender . The helix of a thread can twist in two possible directions, which is known as handedness.

en.m.wikipedia.org/wiki/Screw_thread

Ttapered or Sstraight (parallel). Use a caliper to measure the nominal male or female thread crest-to-crest diameter on the first, fourth, and last full threads (Fig . 1) . T If the diameters increase for a male end or decrease for a female end, the thread is tapered . S If all the diameters are the same, the thread is straight (parallel) .

www.swagelok.com/downloads/webcatalog…

Correspondingly, a threaded nut, an alignment hole, a mounting recess, or sheet metal slot connector is considered to be female. While some mechanical designs are "one-off" custom setups not intended to be repeated, there is an entire fastener industry devoted to manufacturing mass-produced or semi-custom components.

en.m.wikipedia.org/wiki/Gender_of_connect…

What type of thread is used in North America?

What type of thread is used in North America?

This thread type is most commonly used in North America. You’ll recognize it by its tapered outer and inner diameter which is self-sealing. When torqued the flanks of the threads compress against each other forming a leak-tight seal.

trimantec.com/blogs/t/thread-identification …

https://www.trfastenings.com/Products/knowledgebase/Thread-Geometry/Metric-Coarse-Standard

Перевести · Thread Geometry - Metric Coarse. According to ISO965 All Dimensions in mm unless otherwise stated. Tolerances: Male Thread 6g Female Thread: 6h. d1 - Minor thread diameter male. d2 - Minor Thread diameter female. …

https://en.m.wikipedia.org/wiki/Screw_thread

Gender

Every matched pair of threads, external and internal, can be described as male and female. For example, a screw has male threads, while its matching hole (whether in nut or substrate) has female threads. This property is called gender.

Handedness

The helix of a thread can twist in two po…

Gender

Every matched pair of threads, external and internal, can be described as male and female. For example, a screw has male threads, while its matching hole (whether in nut or substrate) has female threads. This property is called gender.

Handedness

The helix of a thread can twist in two possible directions, which is known as handedness. Most threads are oriented so that the threaded item, when seen from a point of view on the axis through the center of the helix, moves away from the viewer when it is turned in a clockwise direction, and moves towards the viewer when it is turned counterclockwise. This is known as a right-handed (RH) thread, because it follows the right hand grip rule. Threads oriented in the opposite direction are known as left-handed (LH).

By common convention, right-handedness is the default handedness for screw threads. Therefore, most threaded parts and fasteners have right-handed threads. Left-handed thread applications include:

• Where the rotation of a shaft would cause a conventional right-handed nut to loosen rather than to tighten due to applied torque or to fretting induced precession. Examples include:

• In combination with right-hand threads in turnbuckles and clamping studs.

• In some gas supply connections to prevent dangerous misconnections, for example:

• In a situation where neither threaded pipe end can be rotated to tighten or loosen the joint (e.g. in traditional heating pipes running through several rooms in a building). In such a case, the coupling will have one right-handed and one left-handed thread.

• In some instances, for example early ballpoint pens, to provide a "secret" method of disassembly.

• In artillery projectiles, anything that screws into the projectile must be given consideration as to what will happen when the projectile is fired, e.g., anything that screws into the base from the bottom of the projectile must be left hand threaded.

• In mechanisms to give a more intuitive action as:

• Some Edison base lamps and fittings (such as those formerly used on the New York City Subway or the pre-World War I Sprague-Thomson rolling stock of the Paris Metro) have a left-hand thread to deter theft, since they cannot be used in other light fixtures.

Form

The cross-sectional shape of a thread is often called its form or threadform (also spelled thread form). It may be square, triangular, trapezoidal, or other shapes. The terms form and threadform sometimes refer to all design aspects taken together (cross-sectional shape, pitch, and diameters), but commonly refer to the standardized geometry used by the screw. Major categories of threads include machine threads, material threads, and power threads.

Most triangular threadforms are based on an isosceles triangle. These are usually called V-threads or vee-threads because of the shape of the letter V. For 60° V-threads, the isosceles triangle is, more specifically, equilateral. For buttress threads, the triangle is scalene.

The theoretical triangle is usually truncated to varying degrees (that is, the tip of the triangle is cut short). A V-thread in which there is no truncation (or a minuscule amount considered negligible) is called a sharp V-thread. Truncation occurs (and is codified in standards) for practical reasons—the thread-cutting or thread-forming tool cannot practically have a perfectly sharp point, and truncation is desirable anyway, because otherwise:

• The cutting or forming tool's edge will break too easily;

• The part or fastener's thread crests will have burrs upon cutting, and will be too susceptible to additional future burring resulting from dents (nicks);

• The roots and crests of mating male and female threads need clearance to ensure that the sloped sides of the V meet properly despite error in pitch diameter and dirt and nick-induced burrs.

• The point of the threadform adds little strength to the thread.

In ball screws, the male-female pairs have bearing balls in between. Roller screws use conventional thread forms and threaded rollers instead of balls.

Angle

The included angle characteristic of the cross-sectional shape is often called the thread angle. For most V-threads, this is standardized as 60 degrees, but any angle can be used. The cross section to measure this angle lies on a plane which includes the axis of the cylinder or cone on which the thread is produced.

Lead, pitch, and starts

Lead /ˈliːd/ and pitch are closely related concepts. They can be confused because they are the same for most screws. Lead is the distance along the screw's axis that is covered by one complete rotation of the screw (360°). Pitch is the distance from the crest of one thread to the next. Because the vast majority of screw threadforms are single-start threadforms, their lead and pitch are the same. Single-start means that there is only one "ridge" wrapped around the cylinder of the screw's body. Each time that the screw's body rotates one turn (360°), it has advanced axially by the width of one ridge. "Double-start" means that there are two "ridges" wrapped around the cylinder of the screw's body. Each time that the screw's body rotates one turn (360°), it has advanced axially by the width of two ridges. Another way to express this is that lead and pitch are parametrically related, and the parameter that relates them, the number of starts, very often has a value of 1, in which case their relationship becomes equality. In general, lead is equal to pitch times the number of starts.

Whereas metric threads are usually defined by their pitch, that is, how much distance per thread, inch-based standards usually use the reverse logic, that is, how many threads occur per a given distance. Thus, inch-based threads are defined in terms of threads per inch (TPI). Pitch and TPI describe the same underlying physical property—merely in different terms. When the inch is used as the unit of measurement for pitch, TPI is the reciprocal of pitch and vice versa. For example, a ⁄4-20 thread has 20 TPI, which means that its pitch is ⁄20 inch (0.050 in or 1.27 mm).

As the distance from the crest of one thread to the next, pitch can be compared to the wavelength of a wave. Another wave analogy is that pitch and TPI are inverses of each other in a similar way that period and frequency are inverses of each other.

Coarse versus fine

Coarse threads are those with larger pitch (fewer threads per axial distance), and fine threads are those with smaller pitch (more threads per axial distance). Coarse threads have a larger threadform relative to screw diameter, where fine threads have a smaller threadform relative to screw diameter. This distinction is analogous to that between coarse teeth and fine teeth on a saw or file, or between coarse grit and fine grit on sandpaper.

The common V-thread standards (ISO 261 and Unified Thread Standard) include a coarse pitch and a fine pitch for each major diameter. For example, ⁄2-13 belongs to the UNC series (Unified National Coarse) and ⁄2-20 belongs to the UNF series (Unified National Fine). Similarly, M10 (10 mm nominal outer diameter) as per ISO 261 has a coarse thread version at 1.5 mm pitch and a fine thread version at 1.25 mm pitch.

The term coarse here does not mean lower quality, nor does the term fine imply higher quality. The terms when used in reference to screw thread pitch have nothing to do with the tolerances used (degree of precision) or the amount of craftsmanship, quality, or cost. They simply refer to the size of the threads relative to the screw diameter.

Coarse threads are more resistant to stripping and cross threading because they have greater flank engagement. Coarse threads install much faster as they require fewer turns per unit length. Finer threads are stronger as they have a larger stress area for the same diameter thread. Fine threads are less likely to vibrate loose as they have a smaller helix angle and allow finer adjustment. Finer threads develop greater preload with less tightening torque.

Diameters

There are three characteristic diameters (⌀) of threads: major diameter, minor diameter, and pitch diameter: Industry standards specify minimum (min.) and maximum (max.) limits for each of these, for all recognized thread sizes. The minimum limits for external (or bolt, in ISO terminology), and the maximum limits for internal (nut), thread sizes are there to ensure that threads do not strip at the tensile strength limits for the parent material. The minimum limits for internal, and maximum limits for external, threads are there to ensure that the threads fit together.

Major diameter

The major diameter of threads is the larger of two extreme diameters delimiting the height of the thread profile, as a cross-sectional view is taken in a plane containing the axis of the threads. For a screw, this is its outside diameter (OD). The major diameter of a nut may not be directly measured, but it may be tested with go/no-go gauges.

The major diameter of external threads is normally smaller than the major diameter of the internal threads, if the threads are designed to fit together. But this requirement alone does not guarantee that a bolt and a nut of the same pitch would fit together: the same requirement must separately be made for the minor and pitch diameters of the threads. Besides providing for a clearance between the crest of the bolt threads and the root of the nut threads, one must also ensure that the clearances are not so excessive as to cause the fasteners to fail.

Minor diameter

The minor diameter is the lower extreme diameter of the thread. Major diameter minus minor diameter, divided by two, equals the height of the thread. The minor diameter of a nut is its inside diameter. The minor diameter of a bolt can be measured with go/no-go gauges or, directly, with an optical comparator.

As shown in the figure at right, threads of equal pitch and angle that have matching minor diameters, with differing major and pitch diameters, may appear to fit snugly, but only do so radially; threads that have only major diameters matching (not shown) could also be visualized as not allowing radial movement. The reduced material condition, due to the unused spaces between the threads, must be minimized so as not to overly weaken the fasteners.

In order to fit a male thread into the corresponding female thread, the female major and minor diameters must be slightly larger than the male major and minor diameters. However this excess does not usually appear in tables of sizes. Calipers measure the female minor diameter (inside diameter, ID), which is less than caliper measurement of the male major diameter (outside diameter, OD). For example, tables of caliper measurements show 0.69 female ID and 0.75 male OD for the standards of "3/4 SAE J512" threads and "3/4-14 UNF JIS SAE-J514 ISO 8434-2". Note the female threads are identified by the corresponding male major diameter (3/4 inch), not by the actual measurement of the female threads.

Pitch diameter

The pitch diameter (PD, or D2) of a particular thread, internal or external, is the diameter of a cylindrical surface, axially concentric to the thread, which intersects the thread flanks at equidistant points, when viewed in a cross-sectional plane containing the axis of the thread, the distance between these points being exactly one half the pitch distance. Equivalently, a line running parallel to the axis and a distance D2 away from it, the "PD line," slices the sharp-V form of the thread, having flanks coincident with the flanks of the thread under test, at exactly 50% of its height. We have assumed that the flanks have the proper shape, angle, and pitch for the specified thread standard. It is generally unrelated to the major (D) and minor (D1) diameters, especially if the crest and root truncations of the sharp-V form at these diameters are unknown. Everything else being ideal, D2, D, & D1, together, would fully describe the thread form. Knowledge of PD determines the position of the sharp-V thread form, the sides of which coincide with the straight sides of the thread flanks: e.g., the crest of the external thread would truncate these sides a radial displacement D − D2 away from the position of the PD line.

Provided that there are moderate non-negative clearances between the root and crest of the opposing threads, and everything else is ideal, if the pitch diameters of a screw and nut are exactly matched, there should be no play at all between the two as assembled, even in the presence of positive root-crest clearances. This is the case when the flanks of the threads come into intimate contact with one another, before the roots and crests do, if at all.

However, this ideal condition would in practice only be approximated and would generally require wrench-assisted assembly, possibly causing the galling of the threads. For this reason, some allowance, or minimum difference, between the PDs of the internal and external threads has to generally be provided for, to eliminate the possibility of deviations from the ideal thread form causing interference and to expedite hand assembly up to the length of engagement. Such allowances, or fundamental deviations, as ISO standards call them, are provided for in various degrees in corresponding classes of fit for ranges of thread sizes. At one extreme, no allowance is provided by a class, but the maximum PD of the external thread is specified to be the same as the minimum PD of the internal thread, within specified tolerances, ensuring that the two can be assembled, with some looseness of fit still possible due to the margin of tolerance. A class called interference fit may even provide for negative allowances, where the PD of the screw is greater than the PD of the nut by at least the amount of the allowance.

The pitch diameter of external threads is measured by various methods:

• A dedicated type of micrometer, called a thread mic or pitch mic, which has a V-anvil and a conical spindle tip, contacts the thread flanks for a direct reading.

• A general-purpose micrometer (flat anvil and spindle) is used over a set of three wires that rest on the thread flanks, and a known constant is subtracted from the reading. (The wires are truly gauge pins, being ground to precise size, although "wires" is their common name.) This method is called the 3-wire method. Sometimes

Doggystyle Granny Porn

Creampie Own

Russian Milf Video

Celebrity Porno Rus

Female Bukkake

Female thread | Article about female thread by The Free ...

Gender of connectors and fasteners - Wikipedia

Thread Geometry - TR Fastenings

Screw thread - Wikipedia

Thread Identification | Hose and Fittings Source

Thread and End Connection - Swagelok

Female Thread