Etelux Glove box laser welding packaging program

When special elements this kind of as semiconductor units, built-in circuits, and optoelectronic units are subjected to laser welding and packaging functions, the welding materials are exposed to the air and are particularly vulnerable to oxidation below higher temperature problems, resulting in welding defects such as porosity, slag inclusions, cracks, and lower welding power. , Major to soaring failure prices such as very poor airtightness, low energy, and impact resistance of the system, particularly the affect resistance defect will trigger hurt to the gadget traveling substantial Mach, leading to major basic safety mishaps and residence losses. At existing, the domestic market urgently demands a The laser welding packaging gadget that can be utilised under vacuum conditions or underneath unique ambiance protection conditions has a very good man-machine setting and versatile tools to meet the demands of substantial-stop products, especially special units for high-speed aerospace autos.

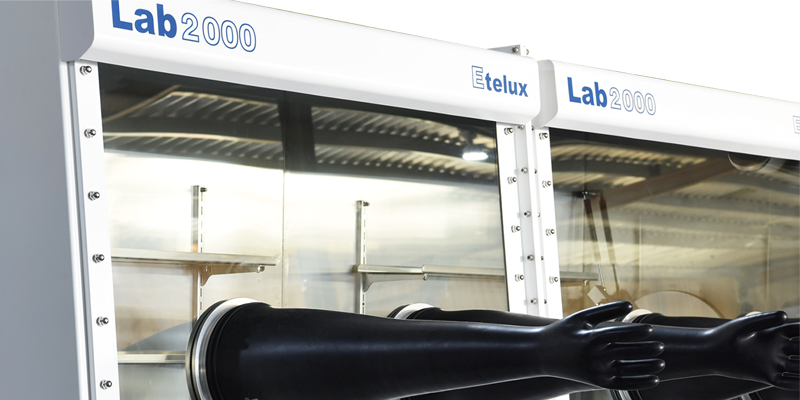

Etelux gives a laser welding glove box primarily based on atmospheric security. To resolve glovebox of air humidity and air impurities in laser welding, the glove box has two ninety-degree sq. cabins, the still left aspect is the heating cabin, and the proper facet For the transitional cabin, the maximum temperature of the heating cabin is two hundred ℃, the heating plate can be cooled speedily at the identical time, the outside of the square cabin door is a handbook doorway, the internal doorway is an automated doorway, the interior and outer doors are interlocked, the glove box is controlled to be cleaned by a flow meter, and can also be linked to the purification program. Its qualities are: low leakage, reduced h2o and oxygen articles in the box, stable all round equipment overall performance, and true and dependable water and oxygen detection.