Enhancing Reliability and Efficiency Diesel Generator Condition Monitoring

Introduction

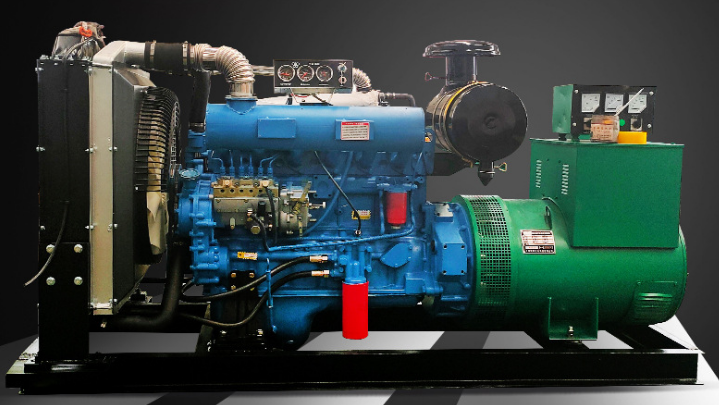

Diesel generators are essential components in various industries, providing backup power during outages and serving as the primary power source in remote locations. To ensure reliable and efficient operation, it is crucial to monitor the condition of diesel generators regularly. Condition monitoring involves the systematic measurement and analysis of key parameters to detect potential issues before they escalate into costly failures. In this article, we will explore the importance of condition monitoring for diesel generators and discuss the various techniques and technologies available for effective monitoring.

Importance of Condition Monitoring for Diesel Generators

Diesel generators play a critical role in ensuring uninterrupted power supply in critical applications such as hospitals, data centers, and manufacturing facilities. A sudden failure of a diesel generator can lead to significant financial losses, operational disruptions, and even safety hazards. By implementing a comprehensive condition monitoring program, operators can proactively identify and address issues that could compromise the reliability and performance of their diesel generators.

One of the key benefits of condition monitoring is the ability to detect early signs of potential failures. By continuously monitoring parameters such as vibration levels, temperature, oil quality, and fuel consumption, operators can identify abnormal trends or patterns that may indicate underlying problems. Early detection allows for timely intervention and preventive maintenance, minimizing downtime and reducing repair costs.

Furthermore, condition monitoring enables operators to optimize the performance of their diesel generators. By analyzing data collected from various sensors and monitoring devices, operators can identify opportunities to improve efficiency, reduce fuel consumption, and extend the lifespan of critical components. This proactive approach to maintenance not only enhances reliability but also contributes to cost savings and environmental sustainability.

Techniques for Diesel Generator Condition Monitoring

There are several techniques and technologies available for monitoring the condition of diesel generators. These include:

1. Vibration Analysis: Vibration analysis is a widely used technique for detecting mechanical issues in diesel generators. By monitoring vibration levels at key components such as bearings, shafts, and rotors, operators can identify abnormalities that may indicate misalignment, imbalance, or wear. Advanced vibration analysis tools can provide real-time data and trend analysis to predict potential failures before they occur.

2. Oil Analysis: Oil analysis is an effective method for assessing the health of a diesel generator's engine and lubrication system. By analyzing oil samples for contaminants, wear particles, and degradation products, operators can detect issues such as excessive wear, overheating, or contamination. Regular oil analysis can help identify maintenance needs, extend oil change intervals, and prevent catastrophic failures.

3. 500KW Diesel Generator For Sale : Thermography involves using infrared cameras to detect abnormal temperature patterns in diesel generator components. By capturing thermal images of key components such as electrical connections, bearings, and cooling systems, operators can identify hotspots that may indicate issues such as loose connections, overheating, or insulation breakdown. Thermography is a non-invasive technique that can be performed during operation, making it a valuable tool for preventive maintenance.

4. Fuel Monitoring: Monitoring fuel quality and consumption is essential for ensuring the reliable operation of a diesel generator. By measuring parameters such as fuel level, pressure, temperature, and contamination, operators can optimize fuel efficiency, prevent fuel-related issues, and detect leaks or theft. Advanced fuel monitoring systems can provide real-time data and alerts to help operators take corrective actions promptly.

5. Remote Monitoring: Remote monitoring systems enable operators to monitor the condition of diesel generators from a centralized location. By connecting sensors, controllers, and monitoring devices to a cloud-based platform, operators can access real-time data, receive alerts, and perform diagnostics remotely. Remote monitoring allows for proactive maintenance planning, predictive analytics, and quick response to critical events, improving overall reliability and efficiency.

Challenges and Considerations

While condition monitoring offers numerous benefits for diesel generators, there are some challenges and considerations that operators need to address:

1. Data Management: Managing the vast amount of data generated by condition monitoring systems can be overwhelming. Operators need to establish clear data collection protocols, storage mechanisms, and analysis tools to ensure that actionable insights are derived from the data effectively.

2. Integration with Maintenance Practices: Condition monitoring should be integrated seamlessly with existing maintenance practices to ensure that identified issues are addressed promptly. Operators need to develop maintenance strategies based on the insights gained from condition monitoring data to maximize the effectiveness of the program.

3. Training and Expertise: Effective condition monitoring requires skilled personnel who are trained in the use of monitoring technologies and data analysis techniques. Operators should invest in training programs and certifications to build a competent team capable of interpreting monitoring data accurately.

4. Cost Considerations: Implementing a comprehensive condition monitoring program can involve upfront costs for equipment, sensors, software, and training. Operators need to weigh the costs against the benefits of improved reliability, reduced downtime, and extended equipment lifespan to justify the investment.

Conclusion

Condition monitoring is a critical practice for enhancing the reliability and efficiency of diesel generators in various industrial applications. By continuously monitoring key parameters such as vibration, oil quality, temperature, and fuel consumption, operators can detect early signs of potential failures, optimize performance, and prevent costly downtime. With the advancement of technologies such as remote monitoring, predictive analytics, and artificial intelligence, operators have access to sophisticated tools for proactive maintenance and data-driven decision-making. By embracing condition monitoring as a core component of their maintenance strategy, operators can ensure the uninterrupted operation of their diesel generators and maximize their operational performance.