Enhancing Food Safety with Video Analytics in the Age of Technology

Nikolas Bush for @issivsIn recent years, the food industry has witnessed significant advancements in technology, transforming the way food is produced, processed, and monitored. One such innovation that has gained tremendous attention is video analytics. Leveraging artificial intelligence and computer vision algorithms, video analytics has emerged as a powerful tool in preventing risks and ensuring food safety throughout the production process. In this article, we will delve into the importance of video analytics in the realm of food production and explore how it can mitigate potential hazards.

The Challenge of Ensuring Food Safety:

The food industry faces numerous challenges when it comes to maintaining food safety standards. Contamination, spoilage, improper handling, and compliance issues pose significant risks to both consumers and producers. Traditional methods of monitoring and quality control are often manual, time-consuming, and prone to human error, leaving room for potential hazards to go unnoticed. This is where video analytics steps in, revolutionizing food production by offering real-time, automated surveillance and analysis capabilities.

Preventing Contamination and Spoilage:

Contamination is a major concern in the food industry. Unidentified foreign objects, such as metal, plastic, or glass, can inadvertently make their way into food products, posing serious health risks to consumers. Video analytics systems equipped with object recognition algorithms can continuously monitor production lines, alerting operators in real-time if any foreign objects are detected. By swiftly identifying and isolating contaminated products, video analytics helps prevent costly recalls and safeguards consumer health.

Similarly, spoilage of perishable food items can occur due to improper storage conditions or delays in processing. Video analytics can monitor environmental factors like temperature, humidity, and lighting in storage facilities and production areas. By analyzing data in real-time and setting thresholds for optimal conditions, the system can promptly alert staff if any deviations occur, allowing for timely corrective actions to prevent spoilage and reduce waste.

Ensuring Proper Handling and Compliance:

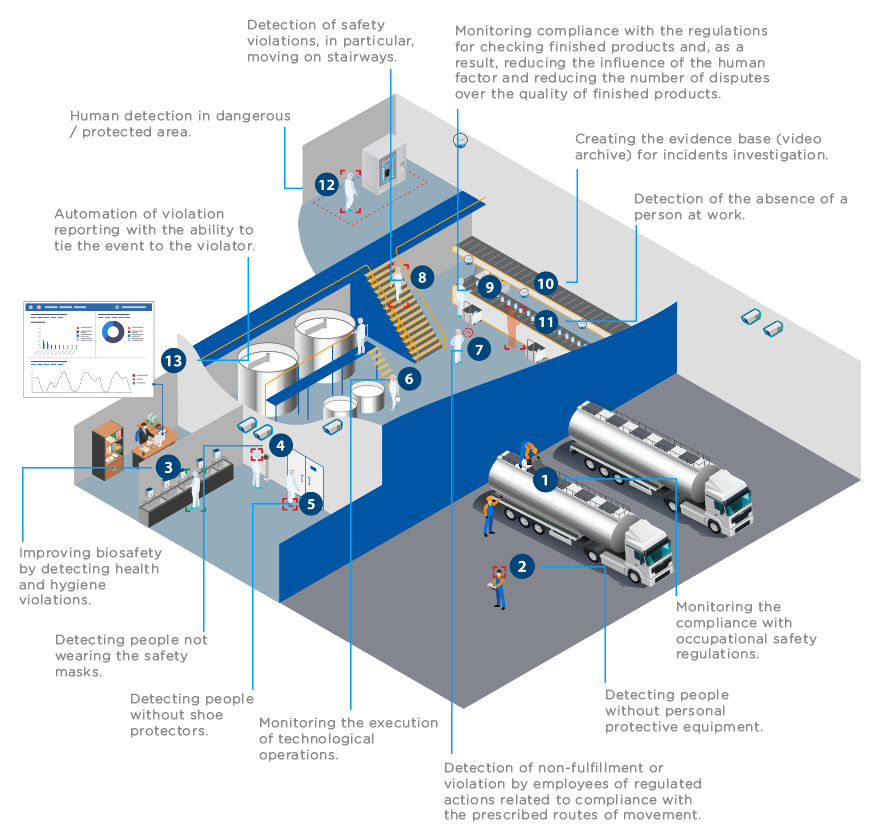

Video analytics can also play a crucial role in monitoring and improving food handling practices, which are essential to maintaining food safety. By installing cameras in food preparation areas, video analytics systems can detect and analyze employee actions in real-time. This enables immediate feedback to ensure adherence to proper hygiene practices, such as handwashing, wearing gloves, and maintaining clean workstations. Automated monitoring not only reduces the risk of contamination but also provides valuable insights for training and process optimization.

Furthermore, compliance with food safety regulations is of paramount importance for food producers. Video analytics can aid in compliance by continuously monitoring production processes to ensure adherence to regulatory guidelines. Whether it is maintaining specific temperatures during cooking or implementing HACCP (Hazard Analysis Critical Control Points) principles, video analytics can assist in identifying potential violations and supporting proactive interventions to rectify non-compliant practices.

Continuous Improvement and Data-Driven Insights:

Video analytics systems not only provide real-time monitoring but also generate valuable data for analysis. By analyzing video footage and metadata, food producers can gain deep insights into production processes, identifying bottlenecks, inefficiencies, and areas for improvement. This data-driven approach allows for continuous optimization of operations, enhanced resource allocation, and better decision-making, ultimately driving overall productivity and profitability.

Conclusion:

As the food industry continues to evolve, ensuring food safety remains a top priority. Video analytics has emerged as a transformative technology, offering real-time monitoring, automated analysis, and proactive risk prevention in food production. By leveraging the power of artificial intelligence and computer vision, video analytics systems can detect and mitigate potential risks such as contamination, spoilage, improper handling, and non-compliance. As a result, food producers can enhance consumer safety, reduce waste, improve operational efficiency, and foster trust in their products. Embracing video analytics in the food industry is a crucial step towards a safer and more sustainable future.

ISS, as a provider of professional video intelligence solutions, offer full-cycle support and maintenance for food processing facilities of all sizes, ranging from consulting and presale to design, deployment, and post-installation services. By harnessing the power of artificial intelligence (AI)-powered algorithms, we deliver autonomous monitoring of personnel actions, resulting in a significant reduction in the number of threats and dangerous situations.

About the author

Nikolas Bush is the VP for APAC at ISS (Intelligent Security Systems), a pioneering and leading organization in the development of video intelligence and data awareness solutions. With over 25 years of experience in the telecom, IT, and security industries worldwide, Nikolas has held executive positions for a number of multinational telecom operators and system integrators. He can be reached at bush@issivs.com.

Subscribe to ISS telegram channel: issivs.t.me

- Enhancing Public Safety: The Power of License Plate Recognition Analytics

- Enhancing Rail Safety and Efficiency: Industry-Leading Under-Train Surveillance System