Diesel Generators for Durability Testing Ensuring Reliability in Critical Applications

**Title: Diesel Generators for Durability Testing: Ensuring Reliability in Critical Applications**

### Introduction

In various industries, the reliability of power sources is paramount. Diesel generators serve as a crucial component in providing backup and emergency power, especially in sectors like healthcare, telecommunications, and manufacturing. As organizations increasingly depend on uninterrupted power supply, the durability of diesel generators becomes a focal point for testing and validation. This article explores the significance of diesel generators in durability testing, the methods used to assess their reliability, and the best practices for ensuring optimal performance in demanding environments.

### Understanding Diesel Generators

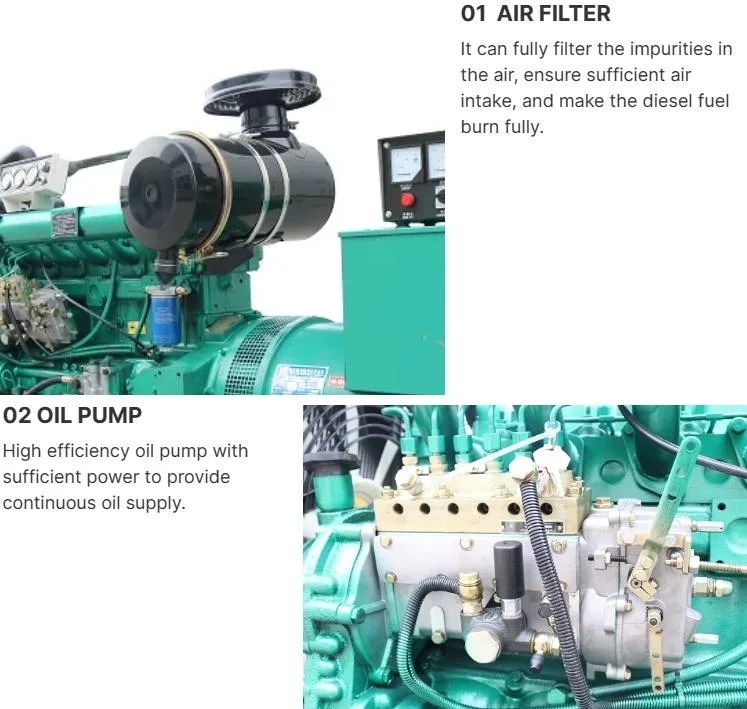

Diesel generators convert diesel fuel into electrical energy through the process of combustion. They consist of a diesel engine, an alternator, a fuel system, a control panel, and various other components that work together to produce electricity. The key features of diesel generators include:

- **Efficiency**: Diesel generators are known for their fuel efficiency and longevity compared to other types of generators.

- **Power Output**: They can provide a wide range of power outputs, from small units suitable for residential use to large generators for industrial applications.

- **Durability**: Designed to operate under demanding conditions, diesel generators are built with robust materials that enhance their lifespan.

### The Importance of Durability Testing

Durability testing is a systematic approach to evaluating how a diesel generator will perform under various conditions over time. The critical reasons for conducting durability testing include:

1. **Reliability Assurance**: In critical applications, it is essential to ensure that the generator will function reliably when needed. Durability testing helps identify potential failure points and ensures consistent performance.

2. **Compliance with Standards**: Many industries have strict regulations and standards that generators must meet, including emissions regulations, efficiency ratings, and safety requirements. Durability testing ensures compliance with these standards.

3. **Cost-Effectiveness**: By identifying weaknesses and potential failures before they occur in real-world applications, organizations can save on repair costs and downtime, leading to more cost-effective operations.

4. **Safety**: In environments where safety is paramount, such as hospitals or data centers, ensuring the reliability of power sources through durability testing can prevent catastrophic failures.

### Methods of Durability Testing

Durability testing for diesel generators involves various methodologies to simulate real-world conditions. The following are some of the most common testing methods:

#### 1. Load Testing

Load testing is a critical aspect of durability testing. It involves running the generator under various load conditions to assess its performance. Key components of load testing include:

- **Full Load Test**: The generator is operated at its rated capacity to evaluate its performance under peak conditions. This test checks for overheating, fuel consumption, and voltage stability.

- **Partial Load Test**: Running the generator at different load levels helps understand how it behaves under various operational scenarios. It is essential for determining fuel efficiency and operational stability.

#### 2. Endurance Testing

Endurance testing involves running the generator continuously over an extended period to simulate long-term use. This testing helps identify wear and tear on components, fuel system performance, and overall reliability. read the article include:

- **Continuous Operation**: The generator must operate for several hours or days, which helps assess how well it maintains performance metrics over time.

- **Monitoring Systems**: During endurance testing, monitoring systems are employed to track temperature, pressure, fuel consumption, and other critical parameters.

#### 3. Environmental Testing

Diesel generators must perform well in various environmental conditions. Environmental testing involves assessing the generator's performance under different temperature, humidity, and altitude conditions. This includes:

- **High-Temperature Testing**: Evaluating how the generator performs in elevated temperatures, which is critical for applications in hot climates.

- **Low-Temperature Testing**: Ensuring reliable start-up and operation in cold conditions, which can affect fuel viscosity and battery performance.

- **Humidity Testing**: Assessing the effects of high humidity on electrical components and fuel systems to prevent corrosion and electrical failures.

#### 4. Vibration and Shock Testing

Generators can be subject to various mechanical stresses during operation, especially in mobile or portable applications. Vibration and shock testing helps evaluate the resilience of the generator against these stresses. This involves:

- **Vibration Analysis**: Running the generator while measuring vibrations to identify potential issues in the engine, mounting, and electrical components.

- **Shock Testing**: Simulating sudden shocks or impacts to evaluate the structural integrity of the generator and its ability to withstand operational stresses.

#### 5. Fuel Quality Testing

The quality of diesel fuel can significantly impact the performance and longevity of diesel generators. Fuel quality testing involves analyzing the fuel for contaminants, viscosity, and other properties. Key considerations include:

- **Contaminant Detection**: Identifying impurities that can clog filters and damage the engine, ensuring that only clean fuel is used.

- **Viscosity Testing**: Ensuring that the fuel is within acceptable viscosity limits for optimal combustion and performance.

### Best Practices for Durability Testing

To ensure effective durability testing of diesel generators, organizations should follow best practices that enhance the reliability of their findings:

#### 1. Develop a Comprehensive Testing Plan

A well-structured testing plan should outline the objectives, parameters, and methodologies for testing. This plan should include timelines, resource allocation, and documentation requirements.

#### 2. Utilize Advanced Monitoring Technology

Employ advanced monitoring systems that provide real-time data on generator performance. This data can help identify issues early and inform decisions on maintenance and operation.

#### 3. Conduct Regular Maintenance

Regular maintenance is crucial for ensuring the longevity of diesel generators. Implement a maintenance schedule that includes inspections, oil changes, filter replacements, and other necessary services.

#### 4. Train Personnel

Ensure that all personnel involved in the operation and testing of diesel generators are adequately trained. Knowledgeable staff can identify issues early and perform necessary adjustments to enhance performance.

#### 5. Document Findings

Maintain thorough documentation of all testing procedures, results, and maintenance activities. This documentation serves as a valuable resource for future reference and compliance purposes.

### Case Studies in Durability Testing

To illustrate the importance of durability testing, we can examine a few case studies where organizations benefited from thorough testing procedures.

#### Case Study 1: Hospital Emergency Power Supply

A major hospital faced challenges with its emergency power supply due to frequent generator failures during testing. By implementing a rigorous durability testing program, the hospital identified several issues related to fuel contamination and insufficient cooling systems. After addressing these problems, the hospital reported a significant improvement in the reliability of its backup power, ensuring patient safety during outages.

#### Case Study 2: Data Center Operations

A data center required a robust backup power solution to maintain uptime for its critical operations. By conducting comprehensive endurance testing on its diesel generators, the center identified performance degradation over extended periods. The findings led to the redesign of the fuel system and the implementation of a more efficient cooling strategy, resulting in enhanced generator performance and reduced downtime.

#### Case Study 3: Remote Telecommunications Tower

A telecommunications company operated a remote tower that relied on a diesel generator for power. Environmental testing revealed that the generator struggled to start in low temperatures, leading to communication outages. By improving the generator's winterization features and conducting regular operational checks, the company ensured seamless communication during harsh weather conditions.

### Future Trends in Durability Testing

As technology continues to evolve, the methods and practices surrounding durability testing for diesel generators are also advancing. Some future trends include:

#### 1. Increased Automation

Automation in testing procedures can enhance efficiency and accuracy. Automated monitoring systems can track performance metrics in real time, allowing for quicker identification of potential issues.

#### 2. Predictive Maintenance

Using data analytics and machine learning, organizations can predict when maintenance is needed based on historical performance data, reducing downtime and improving reliability.

#### 3. Sustainable Practices

As industries move towards sustainability, the focus on cleaner diesel technologies and alternative fuels will influence durability testing. Future tests may include assessments of emissions and fuel efficiency under varying conditions.

#### 4. Integration with Renewable Energy

As diesel generators are often used in conjunction with renewable energy sources, testing will increasingly focus on hybrid systems that combine diesel and solar or wind energy.

### Conclusion

Durability testing of diesel generators is essential for ensuring reliable power supply in critical applications. By employing comprehensive testing methodologies and adhering to best practices, organizations can enhance the performance and longevity of their generators. As technology evolves, the landscape of durability testing will continue to change, incorporating new methodologies and sustainable practices. Ultimately, the goal remains the same: to provide uninterrupted power in a world that increasingly relies on it.