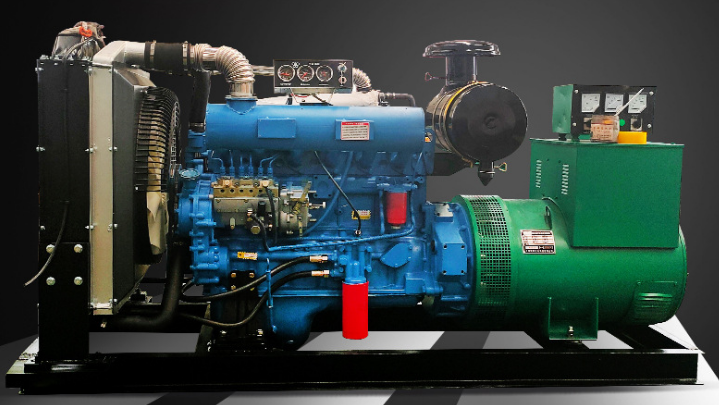

Diesel Generators for Corrosive Atmospheres Ensuring Reliable Power Generation in Challenging Environments

Introduction

Diesel generators play a crucial role in providing backup power in various settings, ensuring continuous operation during power outages. However, in some environments characterized by corrosive atmospheres, traditional diesel generators may face challenges in terms of performance, efficiency, and durability. This article explores the impact of corrosive atmospheres on diesel generators and highlights key considerations for selecting and maintaining generators that can withstand such conditions.

Understanding Corrosive Atmospheres

Corrosive atmospheres are environments where the presence of corrosive agents such as moisture, salt, chemicals, and pollutants can accelerate the degradation of materials. In industrial settings, coastal areas, chemical plants, and offshore platforms are common examples of locations with corrosive atmospheres. These environments pose a significant threat to equipment and machinery, including diesel generators, leading to reduced lifespan and increased maintenance requirements.

Impact on Diesel Generators

Corrosive atmospheres can have several adverse effects on diesel generators, affecting their performance and reliability. Some of the key impacts include:

1. Corrosion of Components: Exposure to corrosive agents can lead to the degradation of critical components of the generator, such as the engine, alternator, and control system. Corrosion can weaken the structural integrity of these components, leading to premature failures and malfunctions.

2. Reduced Efficiency: Corrosion can interfere with the proper functioning of various parts of the generator, affecting its overall efficiency. For example, corrosion on electrical connections can increase resistance and reduce conductivity, leading to energy losses and decreased performance.

3. Increased Maintenance Requirements: In corrosive atmospheres, diesel generators are more prone to wear and tear, requiring more frequent maintenance and servicing. This can result in higher operational costs and downtime, impacting the overall reliability of the backup power system.

4. Safety Risks: Corrosion-induced failures in diesel generators can pose safety risks to personnel and property. Malfunctions in critical components such as fuel systems or electrical systems can result in accidents, fires, or other hazardous situations.

Selecting Diesel Generators for Corrosive Atmospheres

When choosing a diesel generator for use in corrosive atmospheres, several factors should be considered to ensure optimal performance and longevity. Key considerations include:

1. Corrosion-Resistant Materials: Opt for diesel generators constructed from high-quality, corrosion-resistant materials such as stainless steel, aluminum, or coated components. These materials provide better protection against the effects of corrosive atmospheres and help extend the lifespan of the generator.

2. Sealed Enclosures: Select generators with sealed enclosures that prevent the ingress of moisture, dust, and other corrosive agents. Enclosures with IP (Ingress Protection) ratings provide superior protection against environmental factors and help maintain the integrity of the generator's internal components.

3. Protective Coatings: Choose generators with protective coatings on critical components to enhance their resistance to corrosion. Coatings such as epoxy, polyurethane, or ceramic provide an additional layer of defense against corrosive agents and help prolong the generator's lifespan.

4. Ventilation and Filtration Systems: Ensure that the diesel generator is equipped with effective ventilation and filtration systems to maintain a clean and dry environment inside the enclosure. Proper airflow and filtration help prevent the accumulation of corrosive particles and moisture, reducing the risk of corrosion-related damage.

5. Regular Maintenance: Implement a proactive maintenance schedule for the diesel generator, including regular inspections, cleaning, and testing of components. Routine maintenance helps identify and address early signs of corrosion, preventing potential failures and ensuring the continued reliability of the backup power system.

Mitigating Corrosion Risks

In addition to selecting the right diesel generator for corrosive atmospheres, several preventive measures can help mitigate the risks of corrosion and extend the lifespan of the equipment. These include:

1. Environmental Monitoring: Conduct regular assessments of the corrosive atmosphere to identify potential sources of contamination and determine the level of risk to the generator. Monitoring environmental conditions allows for proactive measures to be taken to protect the equipment.

2. Humidity Control: Maintain optimal humidity levels within the generator enclosure to prevent the accumulation of moisture, which can promote corrosion. Installing dehumidifiers or desiccants can help control humidity and protect sensitive components from damage.

3. Corrosion Inhibitors: Use corrosion inhibitors or protective coatings on exposed surfaces of the generator to create a barrier against corrosive agents. These inhibitors form a protective layer that helps prevent the onset of corrosion and prolongs the lifespan of the equipment.

4. Regular Inspections: Schedule regular inspections of the diesel generator to check for signs of corrosion, such as rust, pitting, or discoloration. Prompt identification of corrosion allows for timely intervention and necessary repairs to prevent further damage.

5. Training and Awareness: Provide training to personnel responsible for operating and maintaining the diesel generator on best practices for protecting the equipment from corrosion. Awareness of the risks associated with corrosive atmospheres and proper maintenance procedures can help ensure the longevity and reliability of the generator.

Case Studies and Success Stories

Several industries and organizations have successfully implemented diesel generators in corrosive atmospheres, showcasing the effectiveness of proper selection and maintenance practices. For example:

1. Offshore Oil and Gas Platforms: Oil and gas companies operating offshore platforms face challenging environmental conditions that include high levels of saltwater exposure and corrosive gases. By selecting diesel generators specifically designed for marine environments and implementing rigorous maintenance protocols, these companies have been able to ensure uninterrupted power supply for critical operations.

2. Chemical Processing Plants: Chemical plants often operate in corrosive atmospheres due to the presence of reactive chemicals and fumes. By choosing https://www.lkpowerplant.com/product/special-offer-reliable-high-power-200kw-efficient-diesel-generator-set-for-industrial-use/ with corrosion-resistant materials and implementing regular inspections and maintenance, plant operators have been able to mitigate the effects of corrosion and maintain reliable backup power systems.

3. Coastal Facilities: Buildings located in coastal areas are exposed to saltwater spray and high humidity, which can accelerate corrosion of equipment. By installing diesel generators with protective coatings and implementing humidity control measures, coastal facilities have successfully safeguarded their backup power systems against the corrosive effects of the environment.

Conclusion

Diesel generators are essential for providing backup power in various settings, including those with corrosive atmospheres. Understanding the impact of corrosion on generator performance and reliability is crucial for selecting the right equipment and implementing effective maintenance practices. By choosing corrosion-resistant generators, implementing preventive measures, and conducting regular inspections, organizations can ensure the longevity and reliability of their backup power systems in challenging environments. With proper planning and maintenance, diesel generators can continue to deliver reliable power generation even in the most corrosive atmospheres.