Diesel Generator for Parallel Operation An In-Depth Guide

Introduction

Diesel generators are essential power sources in various industries, commercial establishments, and residential settings where a reliable source of electricity is required. In situations where the power demand exceeds the capacity of a single generator, parallel operation of multiple diesel generators becomes necessary to meet the load requirements effectively. This article aims to provide a comprehensive overview of diesel generators for parallel operation, including their benefits, working principles, system design, synchronization methods, and best practices for efficient and reliable parallel operation.

Benefits of Diesel Generators for Parallel Operation

1. Increased Power Capacity: Parallel operation allows multiple diesel generators to work together to meet higher power demands than what a single generator can handle. By combining the output of several generators, users can achieve a higher total power capacity, making it ideal for applications with fluctuating load requirements or where a backup power supply is critical.

2. Enhanced Reliability: Parallel operation of diesel generators increases system reliability by providing redundancy. If one generator fails or requires maintenance, the remaining units can continue to supply power, ensuring uninterrupted operation. This redundancy is particularly important for critical applications such as data centers, hospitals, and industrial facilities where downtime can result in significant financial losses or safety risks.

3. Improved Efficiency: Operating multiple generators in parallel can lead to improved fuel efficiency and lower operating costs. By distributing the load among several units based on their capacity and efficiency curves, the system can operate closer to its optimal load, reducing fuel consumption per unit of power generated. This optimization helps to minimize fuel wastage and prolong the service life of the generators.

4. Scalability: Parallel operation offers scalability, allowing users to easily expand their power capacity by adding more generators to the system as the load requirements increase. This flexibility makes diesel generators an attractive choice for applications that may undergo future expansions or upgrades, providing a cost-effective solution to meet growing power demands.

Working Principles of Diesel Generators for Parallel Operation

Diesel generators operate on the principle of converting diesel fuel into mechanical energy through combustion, which drives an alternator to produce electrical power. When multiple generators are connected in parallel, they synchronize their outputs to supply a combined load seamlessly. The key components and working principles involved in parallel operation of diesel generators are as follows:

1. Diesel Engine: The diesel engine is the primary component of a generator that converts the chemical energy of diesel fuel into mechanical energy through combustion. Each generator in a parallel system is equipped with its own diesel engine, which drives the generator alternator to produce electricity.

2. Generator Alternator: The generator alternator converts the mechanical energy from the diesel engine into electrical energy through the process of electromagnetic induction. It consists of a rotor (rotating component) and a stator (stationary component) with wire windings that generate an alternating current (AC) output when the rotor spins within a magnetic field.

3. Voltage Regulator: The voltage regulator regulates the output voltage of the generator to maintain it within acceptable limits, typically around 230V or 400V for single-phase or three-phase systems, respectively. In parallel operation, all generators must have their voltage regulators synchronized to ensure that the output voltages are equal and in phase.

4. Governor System: The governor system controls the speed of the diesel engine to maintain a stable frequency output, typically 50Hz or 60Hz depending on the region. In parallel operation, all generators must be synchronized in terms of speed and frequency to prevent load imbalances and ensure smooth operation.

System Design Considerations for Parallel Operation

Designing a diesel generator system for parallel operation requires careful planning and consideration of various factors to ensure optimal performance and reliability. The following are key aspects to consider when designing a parallel operation system:

1. Generator Selection: Selecting the right size and type of generators is crucial for achieving an efficient parallel operation system. Generators should be matched in terms of capacity, voltage output, frequency, and other specifications to ensure compatibility and seamless synchronization. It is recommended to choose generators from the same manufacturer and model series to simplify maintenance and spare parts management.

2. Synchronization Panel: A synchronization panel is a critical component that controls the parallel operation of multiple generators by monitoring and adjusting their voltage, frequency, and phase relationship. The synchronization panel ensures that all generators operate in harmony to supply a balanced load and prevent issues such as voltage fluctuations or frequency deviations.

3. Protection System: A comprehensive protection system is essential to safeguard the generators and the connected load from potential faults or abnormalities during parallel operation. Protection devices such as circuit breakers, relays, and sensors are used to detect overloads, short circuits, under-voltage, over-voltage, and other electrical issues, triggering automatic shutdown or isolation of faulty units to prevent damage.

4. Control System: A centralized control system is used to manage the parallel operation of generators, including starting, stopping, load sharing, and synchronization functions. The control system may include manual or automatic modes of operation, as well as remote monitoring and control capabilities for real-time performance monitoring and troubleshooting.

Synchronization Methods for Parallel Operation

Synchronization is a critical process in parallel operation that ensures all generators are operating in unison to supply a balanced load without causing instability or damage to the system. There are several methods used for synchronizing diesel generators in parallel operation, including:

1. Manual Synchronization: In manual synchronization, operators adjust the speed and voltage of each generator manually to match the desired parameters before connecting them in parallel. This method requires careful monitoring and coordination to ensure that the generators are synchronized accurately to prevent issues such as voltage differentials or frequency deviations.

2. Automatic Synchronization: Automatic synchronization systems use electronic devices and control algorithms to synchronize the generators automatically without manual intervention. The system compares the voltage, frequency, and phase angle of each generator and adjusts them as needed to achieve synchronization within acceptable tolerances. Automatic synchronization reduces the risk of human error and improves the efficiency of parallel operation.

3. Synchronizing Check: Before connecting a generator in parallel, a synchronizing check is performed to verify that the voltage, frequency, and phase angle of the incoming generator match those of the busbar (existing system) within acceptable limits. This check ensures that the connection will not cause disturbances or damage to the system and helps to maintain stability during parallel operation.

Best Practices for Efficient and Reliable Parallel Operation

To ensure efficient and reliable parallel operation of diesel generators, it is essential to follow best practices and guidelines that promote optimal performance and minimize risks. 300kw diesel generator for data centers following are some key best practices for achieving successful parallel operation:

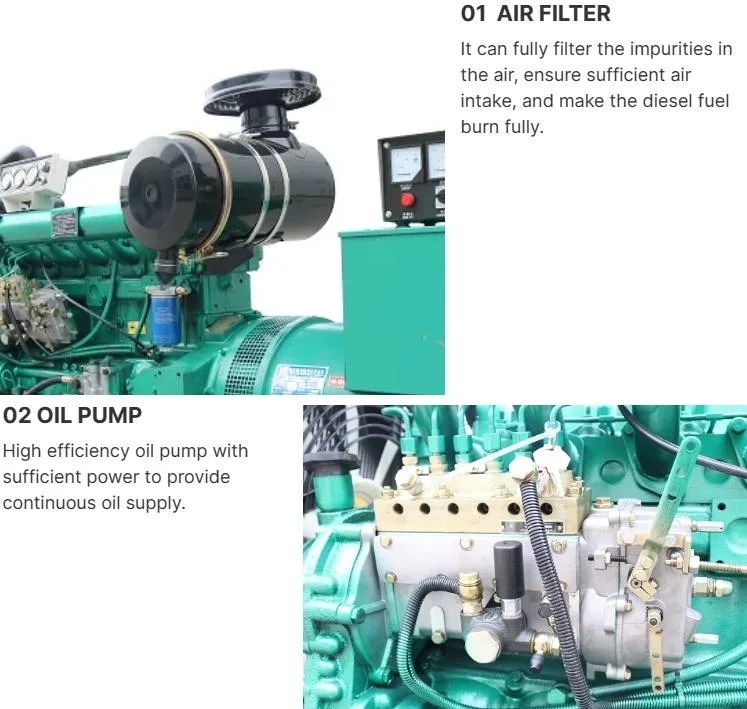

1. Regular Maintenance: Proper maintenance of diesel generators is crucial for their reliable operation in parallel systems. Regular inspections, servicing, and testing of components such as fuel filters, oil filters, air filters, and cooling systems help to prevent breakdowns and extend the service life of the generators. Maintenance schedules should be followed diligently to address any issues proactively and ensure peak performance.

2. Load Sharing: Proper load sharing among generators is essential to prevent overloading or underloading of individual units in a parallel system. Load sharing controls should be configured to distribute the load evenly based on the capacity and efficiency of each generator, ensuring that no unit is overloaded while others remain underutilized. This balance helps to optimize fuel consumption and minimize wear and tear on the equipment.

3. Monitoring and Control: Real-time monitoring and control of the parallel operation system are critical for identifying issues, optimizing performance, and ensuring safe operation. Monitoring parameters such as voltage, frequency, current, power factor, and temperatures enable operators to detect abnormalities or deviations and take corrective actions promptly. Remote monitoring capabilities allow for continuous supervision and quick response to alarms or alerts.

4. Training and Education: Proper training and education of operators and maintenance personnel are essential for the successful operation of diesel generators in parallel systems. Operators should be familiar with the equipment, control systems, synchronization procedures, and safety protocols to handle emergencies and troubleshoot problems effectively. Ongoing training programs help to enhance skills and knowledge, ensuring a competent workforce for managing parallel operation systems.

Conclusion

Diesel generators for parallel operation offer a reliable and efficient solution for meeting high power demands in various applications. By combining the output of multiple generators in parallel, users can achieve increased power capacity, enhanced reliability, improved efficiency, and scalability to adapt to changing load requirements. Understanding the working principles, system design considerations, synchronization methods, and best practices for parallel operation is essential for ensuring the successful and safe operation of diesel generators in parallel systems. By following guidelines and implementing proper maintenance and operational procedures, users can maximize the performance and longevity of their parallel operation systems, providing a dependable source of backup power when needed.