Diecasting: Precision Manufacturing for Fashionable Industries

Diecasting is a manufacturing procedure that plays a critical duty in generating high-precision metal parts used in different sectors. This method includes requiring liquified steel right into a mold cavity under high pressure, producing parts with intricate details and phenomenal precision. Given that its growth in the mid-19th century, diecasting has evolved significantly, coming to be a cornerstone in fields such as auto, aerospace, electronics, and consumer goods. The capacity of diecasting to produce complex forms with constant high quality and performance makes it important in modern production.

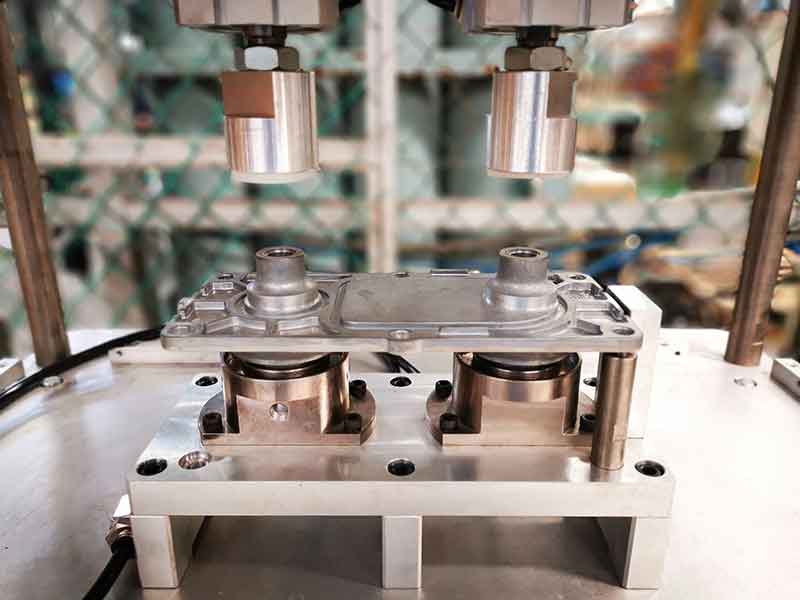

The diecasting procedure begins with the creation of a die, which is a specific mold and mildew made from hardened steel. This die is developed to hold up against the rigors of duplicated usage, making sure that each cast part maintains its exact shape and specs. Once the die is ready, molten steel- commonly aluminum, zinc, magnesium, or copper- is forced into the mold and mildew cavity under high pressure. This stress is important for making certain that the steel loads every contour of the mold, resulting in a part that is both precise and detailed. The fast cooling and solidification of the metal within the die additionally boost the precision of the end product.

Among the primary benefits of diecasting is its capability to produce parts with outstanding dimensional precision and smooth surface areas. This accuracy reduces the need for extra machining and completing, which can save time and lower production expenses. Moreover, diecast components are recognized for their strength and sturdiness, making them excellent for applications that need high performance and dependability. The ability to create complex shapes in a single step also sets diecasting besides various other manufacturing procedures, which might need multiple actions to accomplish the very same result.

Diecasting is also highly effective, both in terms of material use and manufacturing speed. The procedure generates very little waste, as excess metal can be recycled and recycled in subsequent casting procedures. This effectiveness not just makes diecasting an eco-friendly choice but additionally contributes to lower production expenses. Furthermore, diecasting machines can generate a high quantity of components in a reasonably brief quantity of time, making them an optimal option for automation. This capacity is particularly valuable in sectors such as vehicle manufacturing, where big amounts of the same components are needed. To receive supplementary information kindly look at www.senadiecasting.com.my/

In spite of its numerous advantages, diecasting is not without its challenges. The first cost of producing the molds can be high, which might be a barrier for small manufacturing runs. Furthermore, the procedure requires specific control of temperature level and stress to make sure consistent high quality, which can be practically requiring. Developments in modern technology, nonetheless, have actually attended to a number of these difficulties. Modern diecasting machines are furnished with advanced controls and monitoring systems that enhance precision and integrity, making the procedure more obtainable and efficient than in the past.

The future of diecasting looks promising, with recurring advancements poised to more improve the process and broaden its applications. Advancements in materials science are leading to the development of brand-new alloys that supply enhanced mechanical properties and rust resistance. These sophisticated products can boost the performance and long life of diecast components in demanding applications. Additionally, the assimilation of electronic innovations, such as computer-aided style (CAD) and simulation software, is enhancing the die design and optimization process, minimizing preparations and manufacturing prices. As markets remain to look for top notch, cost-effective production remedies, diecasting is readied to play a significantly essential duty in meeting these requirements.