Demystifying Excavator Machines: The Parts

Excavation machines are an vital piece of machinery in construction, gardening, and mining sectors. These powerful machines are known for their versatility and capability to carry out a variety of functions, including excavating profound trenches to lifting heavy loads. However, many people may not completely understand the parts that make up an excavator and how these components work together to ensure effective operation.

In this writing, we will investigate the core components of an excavator, analyzing each section to provide insight on their roles and importance. By demystifying these essential components, we aim to improve your knowledge of this remarkable piece of heavy-duty equipment and its vital role in multiple projects. Whether you are just starting out in the construction industry or simply curious about how excavators work, this resource will provide you with the knowledge you need.

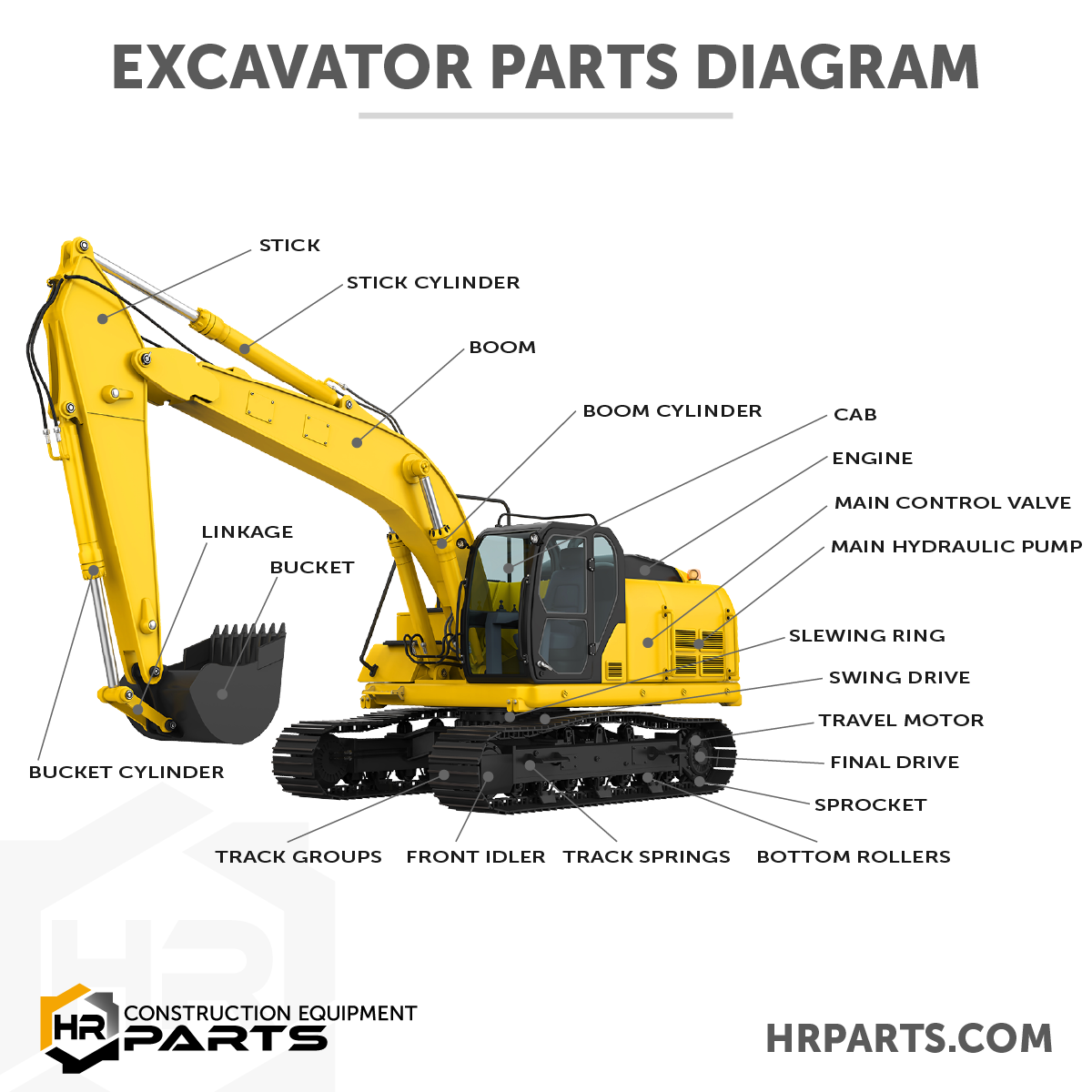

Standard Excavator Components

Diggers are sophisticated machines composed of several key parts that collaborate to perform multiple excavating and hoisting tasks. The cab is one of the most essential parts, as it contains the operator. It includes instruments, gauges, and often a HVAC system to ensure comfort and efficiency while operating the machine. cat parts of the cab differs, but security and visibility are always emphasized to keep the operator aware of their surroundings.

The undercarriage is another essential component of an excavator. It provides stability and mobility, allowing the machine to move across various terrains. This section includes tracks or wheels, depending on the kind of excavator, and has parts such as wheels and sprockets that facilitate movement. A well-designed undercarriage ensures that the excavator can navigate construction sites and difficult landscapes successfully.

The boom and arm assembly are important for the excavating function of the machine. The boom is the long arm that connects to the body of the excavator, providing the extension needed for digging operations. Attached to the boom is the arm, which allows for further extension and movement of the bucket or attachment. Together, these components facilitate a varied tasks, from digging deep trenches to lifting heavy materials, making them essential to the excavator's functions.

Understanding the Hydraulic Mechanism

The hydraulic mechanism is the core of an excavator, providing the force essential for its operations and functions. It works by employing hydraulic liquid, which is compressed and channeled through different components to create motion. This system enhances the excavator's capacity to perform heavy lifting, burrowing, and other demanding tasks with ease. The hydraulic power produced allows for accurate control over the arm, bucket, and pivot capabilities.

At the core of the hydraulic system are hydraulic devices, which are driven by the engine and create the tension required to transport the hydraulic **fluid*. The **fluid travels through a network of hoses and tubes to reach hydraulic actuators. These cylinders convert the hydraulic energy into physical power, enabling the movement of the excavator’s parts. The performance of this system is vital, as it affects how swiftly and efficiently an excavator can function.

Additionally, the hydraulic system includes screens and controls that help maintain optimal performance and security. Filters prevent foreign particles from affecting the components, while controls regulate the flow of the hydraulic fluid. Comprehending the intricacies of the hydraulic system is crucial for anyone wishing to understand how excavators function and why they are able to handle such difficult tasks in industry and other fields.

Maintenance and Safety Advice

Consistent maintenance is crucial for the longevity and optimal operation of excavators. Operators should ensure that all liquid levels, such as engine oil, hydraulic fluid, and coolant, are monitored frequently. Maintaining these fluids at ideal levels not only prevents equipment failures but also boosts the general performance of the machine. Additionally, inspecting filters and replacing them as required can aid in maintaining a clean system, reducing wear and tear on components.

Security should consistently be a main priority when operating excavators. Workers must be properly trained and familiar with the specific model they are operating. Conducting a pre-operation inspection is crucial to identify any likely issues before beginning work. This includes verifying that all safety devices are functioning properly, brakes are in excellent condition, and that wear on tracks or tires is monitored. Workers should also be mindful of their surroundings and ensure that the worksite is clear of hazards, such as overhead power lines.

Ultimately, it is necessary to follow the manufacturer's guidelines for upkeep schedules and to use original parts when repairs are required. Maintaining a log of upkeep tasks can assist track the machine's health and detect trends that may require attention. By focusing on both upkeep and security, operators can ensure that their excavators function efficiently and safely, reducing downtime and enhancing productivity on the job site.