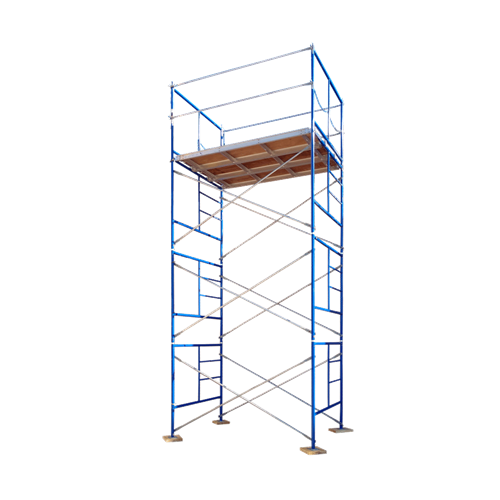

Customized Scaffolding Designs for Facility Constructions

The Makeup of a Scaffold: Understanding Its Elements

To understand the makeup of a scaffold, focus on its key features like supplying stability for employees at diverse elevations and guaranteeing project performance. Parts include steel, light weight aluminum, or timber products made for safety and security and stability. Scaffold frames come in numerous kinds and materials, with adjustable elevations and cross-bracing for assistance. Platforms are critical for employee safety and security, requiring proper weight distribution and secure attachment. Safety measures involve mindful examination, safe base plates, guardrails, and routine checks. Checking out these aspects even more improves expertise of scaffold building and construction and safety treatments.

Trick Functions of a ScaffoldWhat important functions does a scaffold play in various building tasks?

The functions of a scaffold are vital in offering a secure and effective working environment for construction workers. The framework of a scaffold is created to sustain workers, products, and tools at elevated heights during building, upkeep, or fixing jobs. Safety is a primary worry when it comes to scaffolding, and guidelines are in place to ensure that scaffolds are set up, made use of, and took apart appropriately to avoid accidents and injuries.

One crucial function of a scaffold is to give a secure platform for workers to perform jobs at various elevations. The framework of the scaffold should be sturdy and safe to support the weight of workers and materials. Furthermore, scaffolds enable employees to accessibility hard-to-reach locations of a building or framework securely. By complying with safety regulations and standards, such as using proper fall protection tools and evaluating the scaffold regularly, building jobs can be completed successfully and without cases.

Main Parts of a Scaffold

Scaffolds consist of numerous main elements that are essential for ensuring the stability and safety of raised work systems in building and construction tasks. The primary components of a scaffold include scaffold products and scaffold layout. Scaffold products vary based on the requirements of the building project and can consist of steel, aluminum, timber, or a mix of these materials. The scaffold design incorporates the layout and structure of the scaffold, ensuring it can support the intended lots securely.

The selection of scaffold products is crucial in figuring out the strength, durability, and total safety of the scaffold. Steel scaffolds are known for their robustness and capability to support heavy loads, making them suitable for huge building and construction projects. Light weight aluminum scaffolds, on the various other hand, are lightweight yet long lasting, making them excellent for jobs that require constant repositioning. Wood scaffolds are commonly utilized for smaller tasks as a result of their cost-effectiveness.

In scaffold layout, variables such as the scaffold's height, weight ability, and configuration are thoroughly considered to meet security regulations and task demands. Proper scaffold design is essential to prevent crashes and guarantee a safe and secure working environment for building workers.

Recognizing the structural structure of scaffold systems is essential for guaranteeing stability and security on building and construction websites. Scaffold frameworks play a vital role in offering the necessary support for employees and products at different elevations. To comprehend the principle much better, take into consideration the adhering to bottom line concerning scaffold frameworks:

Kinds of Frameworks: Scaffold frameworks been available in various types such as walk-through structures, ladder frames, and masonry structures, each offering particular purposes on building sites.

Material Make-up: Frames are typically built from steel or light weight aluminum, giving durability and stamina to sustain the scaffold structure.

Interlacing Mechanism: Lots of scaffold frameworks include an interlocking system that enables very easy setting up and disassembly, enhancing efficiency on-site.

Adjustable Levels: Some framework kinds use flexible height settings, making it possible for employees to customize the scaffold to suit different project requirements.

Cross-Bracing for Stability: Cross-bracing is often incorporated into structure styles to boost scaffold security and prevent guiding or tipping throughout use.

Comprehending these elements of scaffold frameworks is necessary for making sure a secure and reputable workplace on construction tasks.

Significance of Scaffold PlatformsAnalyzing the critical duty of scaffold platforms in making certain architectural stability and safety at elevated worksites is essential for building and construction specialists.

Scaffold systems serve as the crucial straight frameworks where employees stand, relocate, and do jobs. System security is paramount, as it straight influences the safety and security of workers and the success of the building and construction task.

Appropriate weight distribution on scaffold systems is essential to avoid overloading, which can bring about platform failing and accidents. Making sure that platforms can sustain the designated load ability is important in keeping a risk-free workplace.

Furthermore, scaffold platforms need to be securely connected to the scaffold frame to stop any movement or instability during use. Construction experts should meticulously examine scaffold systems before each usage to recognize any type of indications of damage or put on that might compromise their security.

Precaution for Scaffold Setting UpThinking about the essential nature of scaffold security and platform integrity, the implementation of stringent safety measures during scaffold setting up is important to alleviate risks and assure a secure working environment. Abiding by safety standards and making sure correct training are essential elements of scaffold setting up. Here are five key safety measures to adhere to:

- Check Tools: Before assembly, thoroughly analyze all scaffold components for any damages or issues that can endanger safety.

- Protect Base Plates: Ensure that base plates are firmly positioned on a solid surface to supply security and protect against tipping.

- Usage Guardrails: Mount guardrails on all open sides and ends of the scaffold to prevent drops and enhance worker safety and security.

- Appropriately Planked Platforms: Scaffold platforms should be correctly planked with materials with the ability of supporting desired lots to prevent structural failings.

- Routine Safety And Security Checks: Conduct routine safety evaluations during setting up to identify and attend to any security hazards without delay.

Exist Any Laws or Guidelines for the Optimum Height a Scaffold Can Be Constructed To?

Scaffold stability is crucial in ensuring safety on building sites. Elevation policies determine the optimum acceptable elevation for scaffolds to maintain architectural stability. Safety and security precautions, such as routine examinations and adherence to guidelines, are important, particularly in severe weather.

Can Scaffolds Be Used in Extreme Climate Issues Such as Heavy Rainfall or Snow?

Scaffolds can be utilized in severe weather conditions with proper precautions. Waterproofing techniques like covering with tarpaulins and sealing joints can safeguard against hefty rain. Cold weather safety measures consist of utilizing non-slip surface areas and making sure stability in snow. scaffolding for sale

Just How Usually Should Scaffolds Be Evaluated for Deterioration or Damages?

Scaffolds need to be evaluated frequently according to security requirements to assure structural honesty. Evaluation regularity relies on usage, with many regulations suggesting once a week checks. Regular upkeep methods are crucial for determining wear and tear or damage quickly.

Are There Any Specific Weight Limits for Scaffolds to Make Sure Safety?

Weight restrictions for scaffolds are vital to assure safety on building and construction sites. Security policies normally determine specific weight abilities for different kinds of scaffolding based on their layout and materials. Sticking to these restrictions is important.

What Are Some Common Mistakes or Errors to Avoid When Setting Up a Scaffold?

When creating a scaffold, essential errors to stay clear of include incorrect supporting, forgeting safe and secure footing, making use of harmed elements, going beyond weight limits, and neglecting safety guidelines. Guarantee thorough training, regular inspections, and conformity with guidelines.

Final thoughtTo summarize, understanding the vital features and parts of a scaffold, including frames and platforms, is crucial for assuring safety during assembly.

By sticking to precaution and guidelines, workers can effectively use scaffolds for numerous building tasks.

It is vital to prioritize the appropriate assembly and upkeep of scaffolds to avoid mishaps and guarantee a safe and secure working environment.