Crt Cathode Ray Tube

🛑 👉🏻👉🏻👉🏻 INFORMATION AVAILABLE CLICK HERE👈🏻👈🏻👈🏻

"Picture tube" redirects here. For the PaintShop Pro image type, see PaintShop Pro § Picture tubes.

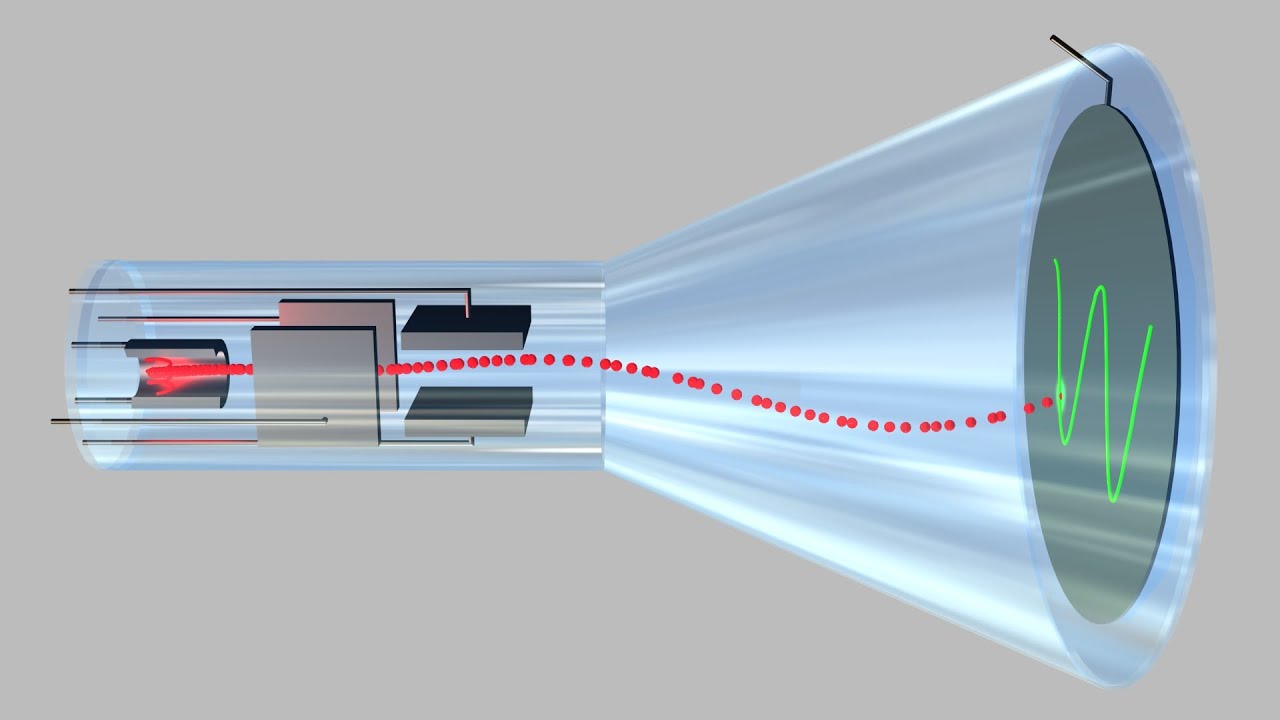

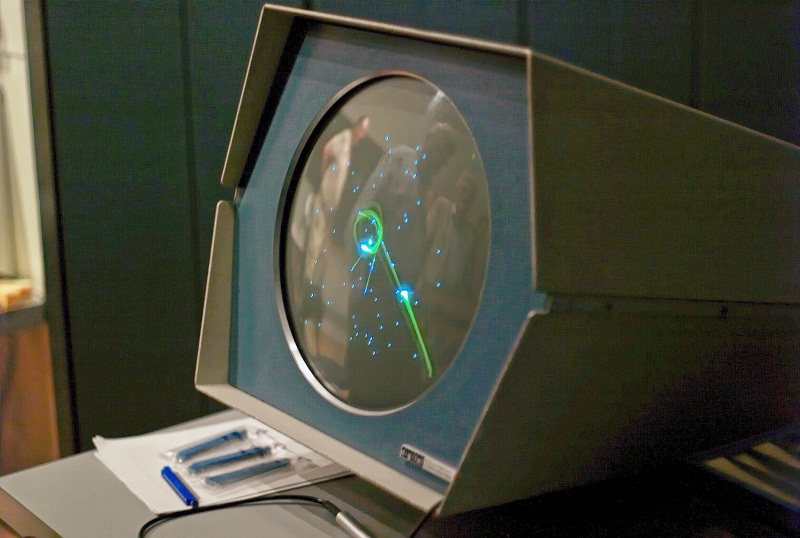

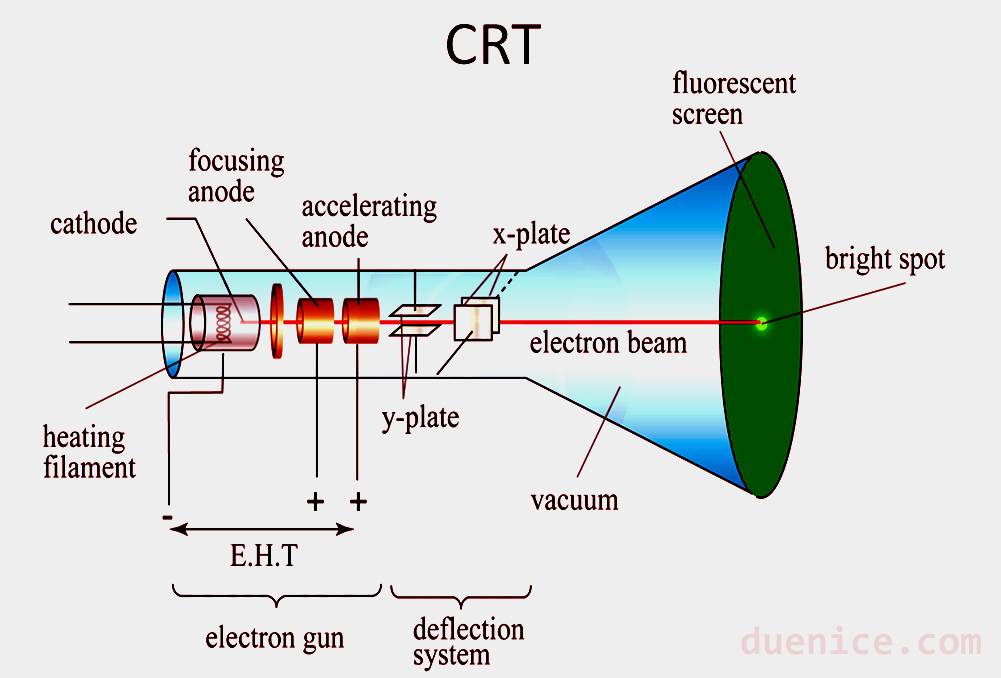

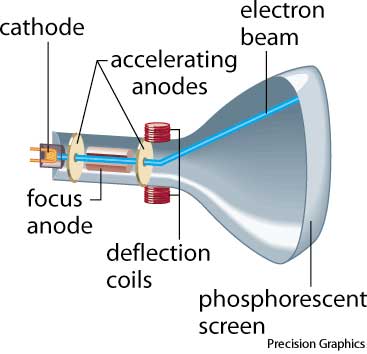

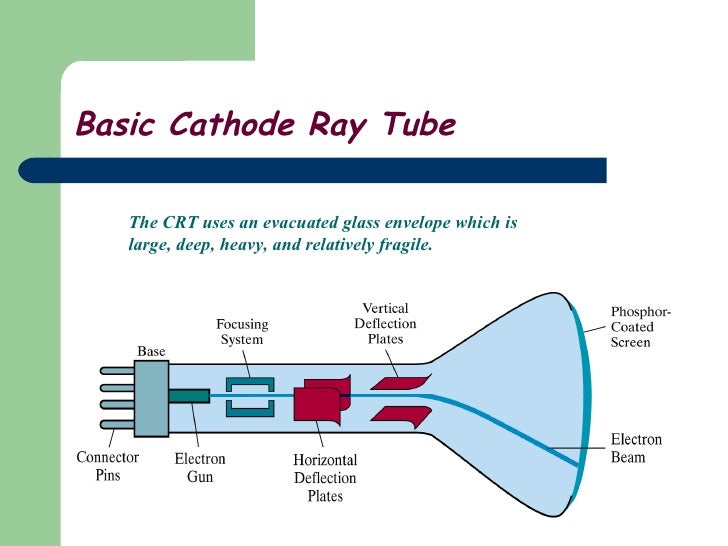

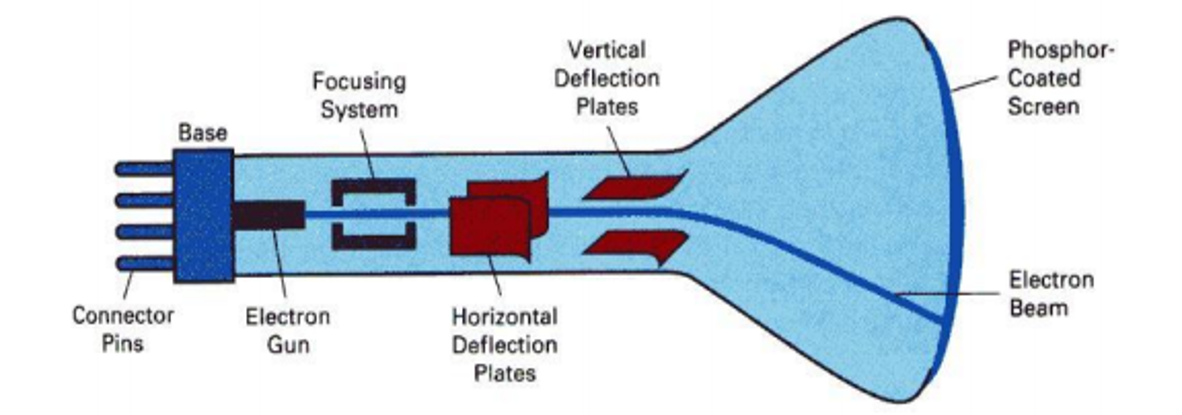

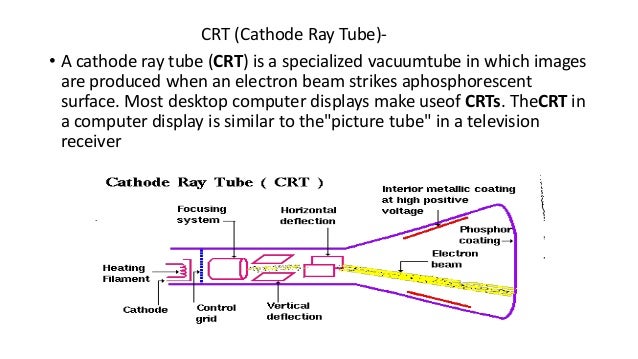

A cathode-ray tube (CRT) is a vacuum tube containing one or more electron guns, the beams of which are manipulated to display images on a phosphorescent screen.[2] The images may represent electrical waveforms (oscilloscope), pictures (television set, computer monitor), radar targets, or other phenomena. A CRT on a television set is commonly called a picture tube. CRTs have also been used as memory devices, in which case the screen is not intended to be visible to an observer.

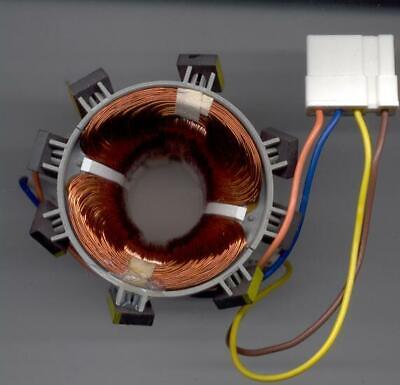

In television sets and computer monitors, the entire front area of the tube is scanned repeatedly and systematically in a fixed pattern called a raster. In color devices, an image is produced by controlling the intensity of each of three electron beams, one for each additive primary color (red, green, and blue) with a video signal as a reference.[3] In modern CRT monitors and televisions the beams are bent by magnetic deflection, using a deflection yoke. Electrostatic deflection is commonly used in oscilloscopes.[3]

A CRT is a glass envelope which is deep (i.e., long from front screen face to rear end), heavy, and fragile. The interior is evacuated to approximately 0.01 pascals (9.9×10−8 atm)[4] to 133 nanopascals (1.31×10−12 atm),[5] to facilitate the free flight of electrons from the gun(s) to the tube's face without scattering due to collisions with air molecules. As such, handling a CRT carries the risk of violent implosion that can hurl glass at great velocity. The face is typically made of thick lead glass or special barium-strontium glass to be shatter-resistant and to block most X-ray emissions. CRTs make up most of the weight of CRT TVs and computer monitors.[6][7]

Since the Early 2010s, CRTs have been superseded by flat-panel display technologies such as LCD, plasma display, and OLED displays which are cheaper to manufacture and run, as well as significantly lighter and less bulky. Flat-panel displays can also be made in very large sizes whereas 40 in (100 cm) to 45 in (110 cm)[8] was about the largest size of a CRT.[9]

A CRT works by electrically heating a tungsten coil[10] which in turn heats a cathode in the rear of the CRT, causing it to emit electrons which are modulated and focused by electrodes. The electrons are steered by deflection coils or plates, and an anode accelerates them towards the phosphor-coated screen, which generates light when hit by the electrons.[11][12][13]

Before the invention of the integrated circuit, CRTs were thought of as the most complicated consumer electronics product.[14]

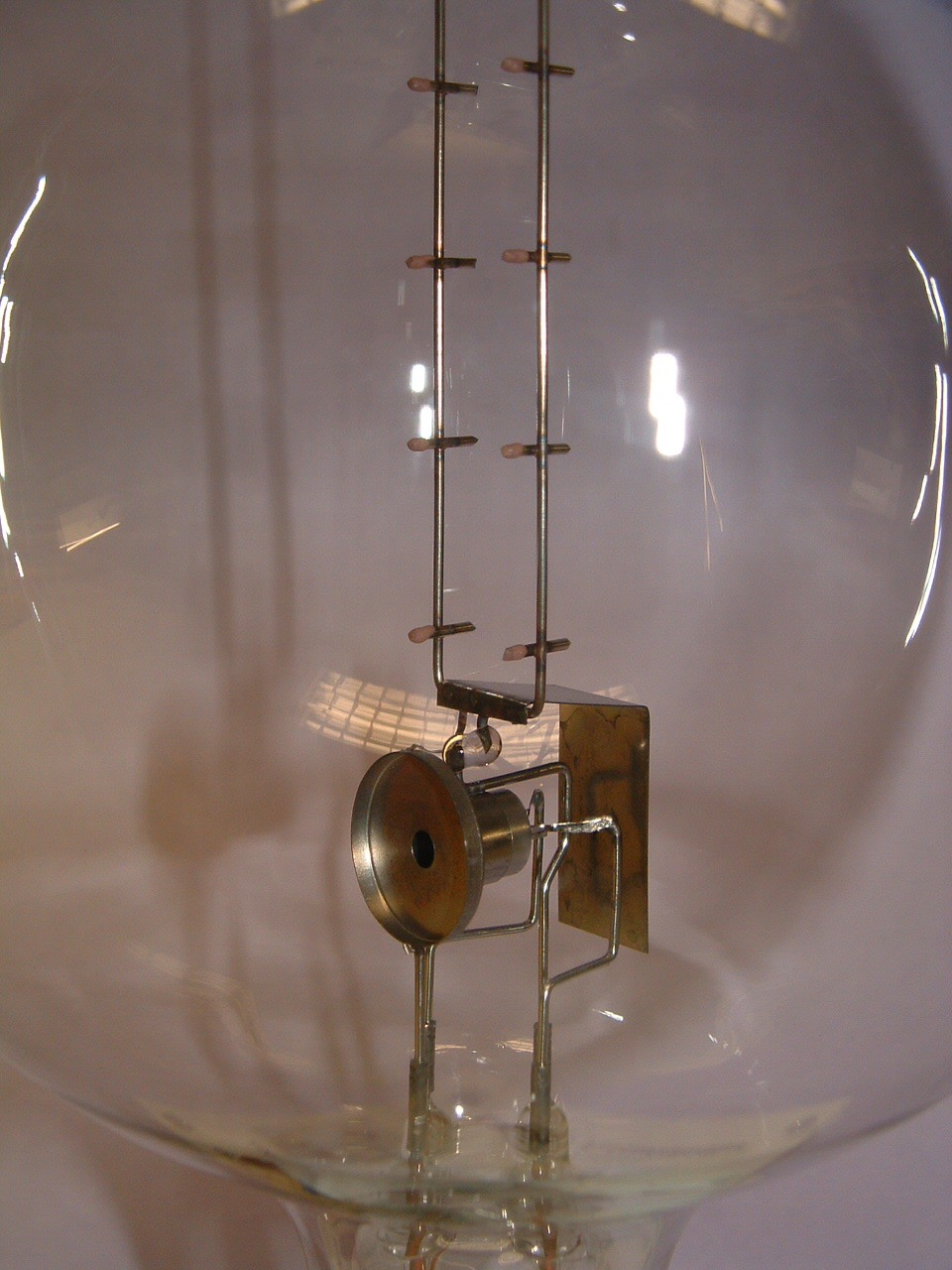

Cathode rays were discovered by Julius Plücker and Johann Wilhelm Hittorf.[15] Hittorf observed that some unknown rays were emitted from the cathode (negative electrode) which could cast shadows on the glowing wall of the tube, indicating the rays were traveling in straight lines. In 1890, Arthur Schuster demonstrated cathode rays could be deflected by electric fields, and William Crookes showed they could be deflected by magnetic fields. In 1897, J. J. Thomson succeeded in measuring the charge-mass-ratio of cathode rays, showing that they consisted of negatively charged particles smaller than atoms, the first "subatomic particles", which had already been named electrons by Irish physicist, George Johnstone Stoney in 1891. The earliest version of the CRT was known as the "Braun tube", invented by the German physicist Ferdinand Braun in 1897.[16] It was a cold-cathode diode, a modification of the Crookes tube with a phosphor-coated screen. Braun was the first to conceive the use of a CRT as a display device.[17]

In 1908, Alan Archibald Campbell-Swinton, fellow of the Royal Society (UK), published a letter in the scientific journal Nature in which he described how "distant electric vision" could be achieved by using a cathode ray tube (or "Braun" tube) as both a transmitting and receiving device.[18][19] He expanded on his vision in a speech given in London in 1911 and reported in The Times[20] and the Journal of the Röntgen Society.[21][22]

The first cathode-ray tube to use a hot cathode was developed by John Bertrand Johnson (who gave his name to the term Johnson noise) and Harry Weiner Weinhart of Western Electric, and became a commercial product in 1922.[citation needed] The introduction of hot cathodes allowed for lower acceleration anode voltages and higher electron beam currents, since the anode now only accelerated the electrons emitted by the hot cathode, and no longer had to have a very high voltage to induce electron emission from the cold cathode.[23]

In 1926, Kenjiro Takayanagi demonstrated a CRT television that received images with a 40-line resolution.[24] By 1927, he improved the resolution to 100 lines, which was unrivaled until 1931.[25] By 1928, he was the first to transmit human faces in half-tones on a CRT display.[26] By 1935, he had invented an early all-electronic CRT television.[27]

It was named in 1929 by inventor Vladimir K. Zworykin,[28] who was influenced by Takayanagi's earlier work.[26] RCA was granted a trademark for the term (for its cathode-ray tube) in 1932; it voluntarily released the term to the public domain in 1950.[29]

In the 1930s, Allen B. DuMont made the first CRTs to last 1,000 hours of use, which was one of the factors that led to the widespread adoption of television.[30]

The first commercially made electronic television sets with cathode-ray tubes were manufactured by Telefunken in Germany in 1934.[31][32]

In 1947, the cathode-ray tube amusement device, the earliest known interactive electronic game as well as the first to incorporate a cathode-ray tube screen was created.[33]

From 1949 to the early 1960s, there was a shift from circular CRTs to rectangular CRTs, although the first rectangular CRTs were made in 1938 by Telefunken.[34][23][35][36][37][38] While circular CRTs were the norm, European TV sets often blocked portions of the screen to make it appear somewhat rectangular while American sets often left the entire front of the CRT exposed or only blocked the upper and lower portions of the CRT.[39][40]

In 1954, RCA produced some of the first color CRTs, the 15GP22 CRTs used in the CT-100,[41] the first color TV set to be mass produced.[42] The first rectangular color CRTs were also made in 1954.[43][44] However, the first color rectangular CRTs to be offered to the public were made in 1963. One of the challenges that had to be solved to produce the rectangular color CRT was convergence at the corners of the CRT.[37][36] In 1965, brighter rare earth phosphors began replacing dimmer and cadmium-containing red and green phosphors. Eventually blue phosphors were replaced as well.[45][46][47][48][49][50]

The size of CRTs increased over time, from 19 inches in 1938,[51] to 21 inches in 1955,[52][53] 35 inches by 1985,[54] and 43 inches by 1989.[55] However, experimental 31 inch CRTs were made as far back as 1938.[56]

In 1960, the Aiken tube was invented. It was a CRT in a flat-panel display format with a single electron gun.[57][58] Deflection was electrostatic and magnetic but due to patent problems it was never put into production. It was also envisioned as a Head-up display in aircraft.[59] By the time patent issues were solved RCA had already invested heavily in conventional CRTs.[60]

In 1987, flat-screen CRTs were developed by Zenith for computer monitors, reducing reflections and helping increase image contrast and brightness.[61][62] Such CRTs were expensive which limited their use to computer monitors.[63] Attempts were made to produce flat-screen CRTs using inexpensive and widely available float glass.[64]

In 1990, the first CRTs with HD resolution were released to the market by Sony.[65]

In the mid 1990s, some 160 million CRTs were made per year.[66]

Flat-panel displays dropped in price and started significantly displacing cathode-ray tubes in the 2000s. After several predictions,[67][68] LCD monitor sales began exceeding those of CRTs in 2003-2004[69][70][71] and LCD TV sales started exceeding those of CRTs in the US in 2005,[72] in Japan in 2005-2006,[73][74][75] in Europe in 2006,[76] globally in 2007-2008,[77][78] and in India in 2013.[79]

In the mid 2000s, Canon and Sony presented the surface-conduction electron-emitter display and field-emission displays, respectively. They both were flat-panel displays that had one (SED) or several (FED) electron emitters per subpixel in place of electron guns; the electron emitters were placed on a sheet of glass and the electrons were accelerated to a nearby sheet of glass with phosphors using an anode voltage; the electrons were not focused making each subpixel essentially a flood gun CRT. They were never put into mass production as LCD technology was significantly cheaper, eliminating the market for such displays.[80]

The last known manufacturer of (in this case, recycled)[81] CRTs, Videocon, ceased in 2015.[82][83] CRT TVs stopped being made around the same time.[84]

In 2015, several CRT manufacturers were convicted in the US for price fixing. The same occurred in Canada in 2018.[85][86]

Worldwide sales of CRT computer monitors peaked in 2000, at 90 million units, while those of CRT TVs peaked in 2005 at 130 million units.[87]

Beginning in the late 90s to the early 2000s CRTs began to be replaced with LCDs, starting first with computer monitors smaller than 15 inches in size[88] largely because of their lower bulk.[89] Among the first[90] manufacturers to stop CRT production was Hitachi, in 2001,[91][92] followed by Sony in Japan in 2004,[93] Thomson in the US in 2004,[94][95] Matsushita Toshiba picture display in 2005 in the US,[96] 2006 in Malaysia[97] and 2007 in China,[98] Sony in the US in 2006,[99] Sony in Singapore and Malaysia for the Latin American and Asian markets in 2008,[93][100] Samsung SDI in 2007[101][102] and 2012[103][104] and Cathode Ray Technology(formerly Philips) in 2012[105][106] and Videocon in 2015-16.[107][108][109][82] Ekranas in Lithuania[110] and LG.Philips Displays[111] went bankrupt in 2005 and 2006 respectively. Matsushita Toshiba stopped in the US in 2004 due to losses of $109 million,[112] and in Malaysia in 2006 due to losses that almost equaled their sales.[97] The last CRT TVs at CES were shown by Samsung in 2007[113] and the last mass produced model was introduced by LG in 2008 for developing markets due to its low price.[114][115] The last CRT TV by a major manufacturer was introduced by LG in 2010.[116][117]

CRTs were first replaced by LCD in developed markets such as Japan and Europe in the 2000s and continued to be popular in developing markets such as Latin America,[118][87] China, Asia and the Middle East due to their low price compared to contemporary flat panel TVs,[119] and later in markets like rural India, however in around 2014 even rural markets started favoring LCD over CRT, leading to the demise of the technology.[120]

Despite being a mainstay of display technology for decades, CRT-based computer monitors and televisions are now virtually a dead technology. Demand for CRT screens dropped in the late 2000s. The rapid advances and falling prices of LCD flat panel technology — first for computer monitors, and then for televisions — spelled doom for competing display technologies such as CRT, rear-projection, and plasma display.[121] Despite efforts from Samsung and LG to make CRTs competitive with their LCD and plasma counterparts, offering slimmer and cheaper models to compete with similarly sized and more expensive LCDs,[122][123][124][125][126] CRTs eventually became obsolete and were relegated to developing markets once LCDs fell in price, with their lower bulk, weight and ability to be wall mounted coming as pluses.

Most high-end CRT production had ceased by around 2010,[127] including high-end Sony and Panasonic product lines.[128][129] In Canada and the United States, the sale and production of high-end CRT TVs (30-inch (76 cm) screens) in these markets had all but ended by 2007. Just a couple of years later, inexpensive "combo" CRT TVs (20-inch (51 cm) screens with an integrated VHS player) disappeared from discount stores.

Electronics retailers such as Best Buy steadily reduced store spaces for CRTs. In 2005, Sony announced that they would stop the production of CRT computer displays. Samsung did not introduce any CRT models for the 2008 model year at the 2008 Consumer Electronics Show; on 4 February 2008, they removed their 30" wide screen CRTs from their North American website and did not replace them with new models.[130]

In the United Kingdom, DSG (Dixons), the largest retailer of domestic electronic equipment, reported that CRT models made up 80–90% of the volume of televisions sold at Christmas 2004 and 15–20% a year later, and that they were expected to be less than 5% at the end of 2006. Dixons ceased selling CRT televisions in 2006.[131]

CRTs' demise has made maintaining arcade machines made before the wide adoption of flat-panel displays difficult, due to a lack of spare replacement CRTs. (CRTs may need replacement due to wear as explained further below.) Repairing CRTs, although possible, requires a high level of skill.[132]

While CRTs had declined dramatically in the late 2000s, they are still widely used by consumers and some industries. CRTs do have some distinct advantages over other newer technologies.

Because a CRT doesn't need to draw a full image and instead uses interlaced lines, a CRT is faster than an LCD which draws the entire image. CRTs are also able to correctly display certain resolutions, such as the 256x224 resolution of the Nintendo Entertainment System (NES).[133] This is also an example of the most common usage of CRTs by consumers, retro video gaming. Some reasons for this include:

Some industries still use CRTs because it is either too much effort, downtime, and/or cost to replace them, or there is no substitute available; a notable example is the airline industry. Planes such as the Boeing 747-400 and the Airbus A320 used CRT instruments in their glass cockpits instead of mechanical instruments.[134] Airlines such as Lufthansa still use CRT technology, which also uses floppy disks for navigation updates.[135]

CRTs also tend to be more rugged than their flat panel counterparts,[11] although rugged LCDs also exist.

On CRTs, refresh rate depends on resolution, both of which are ultimately limited by the maximum horizontal scanning frequency of the CRT; motion blur also depends on the decay time of the phosphors; phosphors that decay too slowly for a given refresh rate may cause smearing or motion blur on the image. In practice CRTs are limited to a refresh rate of 160hz.[143] LCDs that can compete with OLED (Dual Layer, and mini-LED LCDs) are not available in high refresh rates, although quantum dot LCDs (QLEDs) are available in high refresh rates (up to 144Hz)[144] and are competitive in color reproduction with OLEDs.[145]

CRT monitors can still outperform LCD and OLED monitors in input lag, as there is no signal processing between the CRT and the display connector of the monitor, since CRT monitors often use VGA which provides an analog signal that can be fed to a CRT directly. Video cards designed for use with CRTs may have a RAMDAC to generate the analog signals needed by the CRT.[146][11] Also, CRT monitors are often capable of displaying sharp images at several resolutions, an ability known as multisyncing.[147] Due to these reasons CRTs are sometimes preferred by PC gamers in spite of their bulk, weight and heat generation.[148][137]

The body of a CRT is usually made up of three parts: A screen/faceplate/panel, a cone/funnel, and a neck.[149][150][151][152][153] The joined screen, funnel and neck are known as the bulb or envelope.[36]

The neck is made from a glass tube[154] while the funnel and screen are made by pouring and then pressing glass into a mold.[155][156][157][158][159] The glass, known as CRT glass[160][161] or TV glass,[162] needs special properties to shield against x-rays while providing adequate light transmission in the screen or being very electrically insulating in the funnel and neck. The formulation that gives the glass its properties is also known as the melt. The glass is of very high quality, being almost contaminant and defect free. Most of the costs associated with glass production come from the energy used to melt the raw materials into glass. Glass furnaces for CRT glass production have several taps to allow molds to be replaced without stopping the furnace, to allow production of CRTs of several sizes. Only the glass used on the screen needs to have precise optical properties. The optical properties of the glass used on the screen affects color reproduction and purity in Color CRTs. Transmittance, or how transparent the glass is, may be adjusted to be more transparent to certain colors (wavelengths) of light. Transmittance is measured at the center of the screen with a 546nm wavelength light, and a 10.16mm thick screen. Transmittance goes down with increasing thickness. Standard transmittances for Color CRT screens are 86%, 73%, 57%, 46%, 42% and 30%. Lower transmittances are used to improve image contrast but they put more stress on the electron gun, requiring more power on the electron gun for a higher electron beam power to light the phosphors more brightly to compensate for the reduced transmittance.[63][163] The transmittance must be uniform across the screen to ensure color purity. The radius (curvature) of screens has increased (grown less curved) over time, from 30 to 68 inches, ultimately evolving into completely flat screens, reducing reflections. The thickness of both curved[164] and flat screens graudally increases from the center outwards, and with it, transmittance is gradually reduced. This means that flat-screen CRTs may not be completely flat on the inside.[164][165] The glass used in CRTs arrives from the glass factory to the CRT factory as either separate screens and funnels with fused necks, for Color CRTs, or as bulbs made up of a fused screen, funnel and neck. There were several glass formulations for different types of CRTs, that were classified using codes specific to each glass manufacturer. The compositions of the melts were also specific to each manufacturer.[166] Those optimized for high color purity and contrast were doped with Neodymium, while those for monochrome CRTs were tinted to differing levels, depending on the formulation used and had transmittances of 42% or 30%.[167] Purity is ensuring that the correct colors are activated (for example, ensuring that red is displayed uniformly across the screen) while convergence ensures that images are not distorted. Convergence may be modified using a cross hatch pattern.[168][169][170]

CRT glass used to be made by dedicated companies[171] such as AGC Inc.,[172][173][174] O-I Glass,[175] Samsung Corning Prec

Spankingserver Only Spanking

Moms Try Sons

Private Gold 121

Curvy Busty Big Tits Ass

Rae Lil Black Bdsm

Cathode-ray tube - Wikipedia

Cathode Ray Tubes (CRTs) | US EPA

Cathode-ray tube - Wikipedia

What is Cathode Ray Tube (CRT)? - Definition, Working ...

What is CRT (Cathode Ray Tube)? | SYSNETTECH Solutions

Cathode Ray Tube (CRT) | Science Facts

Cathode Ray Tubes | Chemdemos

Cathode Ray Tube (CRT) Construction and Working

CRT(Cathode Ray Tube) Display and its Parts

Crt Cathode Ray Tube