Cost-Effective Strategies For Petroleum Equipment Maintenance And Repairs

Marshall NoahPetroleum equipment is crucial in the petroleum industry. It contributes significantly impact on the smooth operation of businesses. To ensure optimal functionality and prevent expensive downtime, it is vital to prioritize regular maintenance and timely repairs.

This blog will delve into cost-effective strategies for maintaining and repairing petroleum equipment. So, without further ado, let's dive right in.

Importance Of Petroleum Equipment Maintenance And Repair

Timely repairs also help to identify and rectify minor issues before they escalate into major problems, ultimately saving costs in the long run. Also, proper maintenance and repair contribute to the safety of employees, customers, and the environment, ensuring compliance with industry regulations. Overall, investing in petroleum equipment maintenance and repair is essential for a sustainable and profitable operation in the petroleum industry.

1- Regular Preventive Maintenance

Regular preventive maintenance is the cornerstone of cost-effective equipment management. By implementing a proactive maintenance plan, businesses can identify and address minor issues before they escalate into major problems. This approach minimizes the likelihood of unexpected breakdowns, reduces repair costs, and extends the lifespan of the equipment.

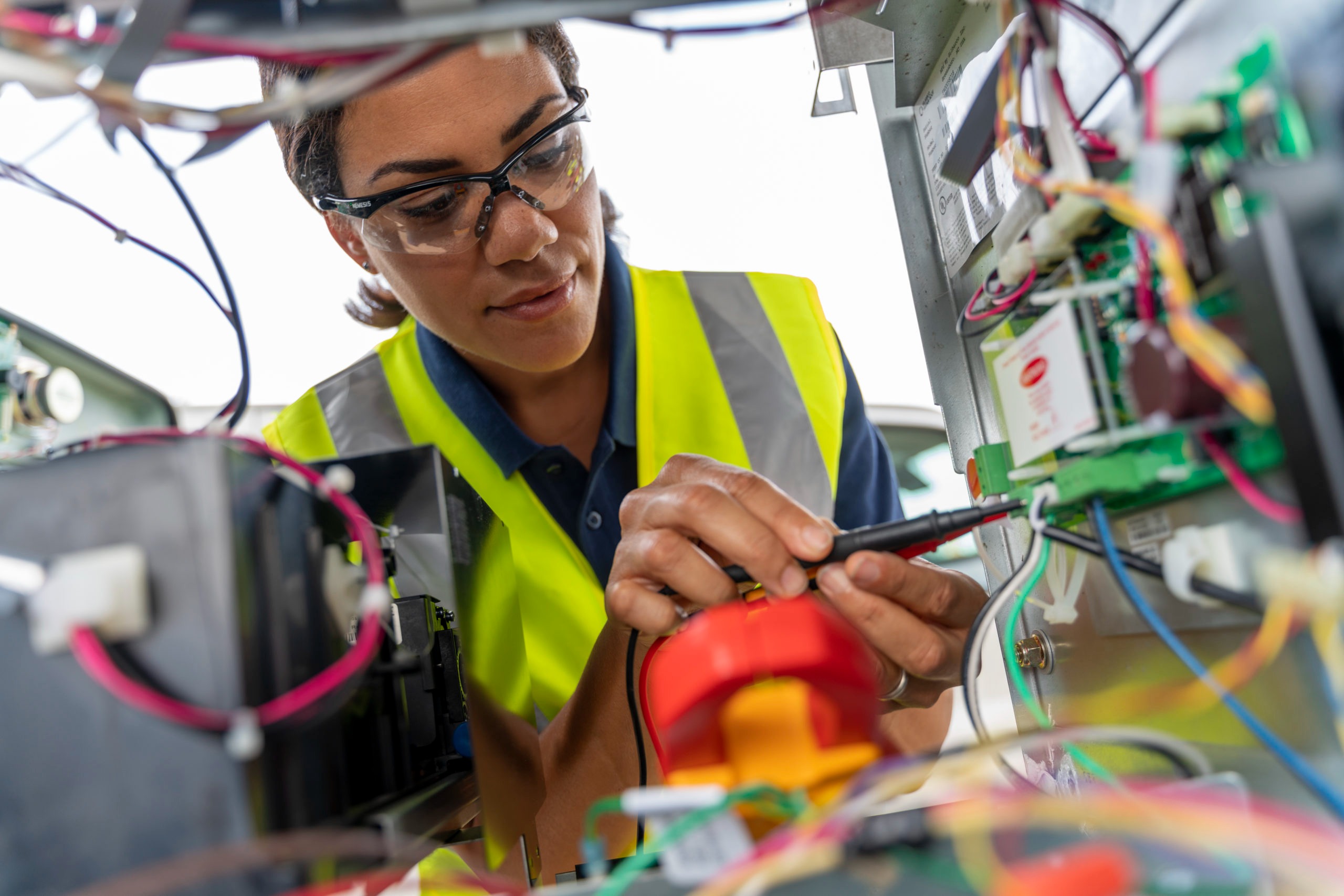

Professional petroleum equipment services can help streamline preventive maintenance, ensuring thorough inspections and timely servicing.

2- Training And Education

Investing in training and education for maintenance staff is a wise strategy to optimize equipment maintenance and repair efforts. Equipping technicians with the necessary skills and knowledge to identify and resolve issues efficiently can significantly reduce downtime and associated costs.

Training programs provided by petroleum equipment services can cover various aspects, including safety protocols, troubleshooting techniques, and preventive maintenance procedures.

3- Utilizing Technology

Leveraging technological advancements can greatly enhance maintenance and repair processes. For example, advanced monitoring systems, such as IoT sensors and predictive analytics, allow for real-time equipment performance monitoring and early detection of potential failures.

This proactive approach helps businesses to schedule maintenance activities strategically. Petroleum equipment services often offer integrated technology solutions according to specific equipment needs.

4- Documentation And Record-Keeping

Maintaining accurate documentation and records of equipment maintenance and repairs is essential for cost-effective management. Detailed descriptions help businesses to track the maintenance history, identify recurring issues, and plan future maintenance schedules effectively. Many petroleum equipment services provide digital platforms or software solutions to streamline documentation and record-keeping processes.

5- Prioritizing Safety

Safety should always be a top priority for petroleum equipment maintenance and repairs. Regular safety audits, training programs, and strict adherence to maintenance procedures recommended by service providers will create a safe working environment.

Final Words

Petroleum equipment like canopies, fuel dispensers, gauges, hoses, and valves requires extra attention for maintenance. Regular inspection and maintenance of gas station canopies and other equipment are necessary to ensure structural integrity, prevent potential hazards, and avoid costly repairs or replacements.

Power Up Your Petroleum Operations with APEC - Unleashing Efficiency, Reliability, and Innovation for Unparalleled Success. We are here to guide you 24/7 for more details visit our site now!