Comprehensive Guide To General Purpose Polyester Resin

Vaishali AegisPolyester Resin for gp:

The general purpose unsaturated polyester resin is extensively used in industrial purposes, chemical equipment, auto industry, marine industry, and FRP cooler bodies. They are fabricated with an innovative technique of production to meet international quality standards. We compile with requirements of industries interested in superior performance and improved efficiency of their finished product.

General applications of polyester resin:

· Flowerpot

· Automobile components

· Dust bin

· Sports equipment

· Water tank

· Safety helmet

· Garden furniture

· Container

· Bathtub

· Panels

· Statues

· Machine cover

Product features and benefits:

The polyester resin for gp is a quick curing unsaturated polyester resin that depends on the orthophthalic raw material for laminating purposes. It serves longer-term and ideal for both gun spray-up and layup. The resin offers outstanding mechanical properties, influence, and water resistance. The glass fiber laminate formed with this resin has good rigidity, excellent mechanical strength, and exceptional durability.

· Medium reactivity

· Muddy yellow and transparent in color

· Efficient heat resistance

· Good water resistance

Post curing:

It is suggested to mature the products for 24 hours, and post-curing should be operated for a minimum of three hours at 2-3 hours or 800 Celsius at room temperature. It is vital for getting the best properties.

Usage:

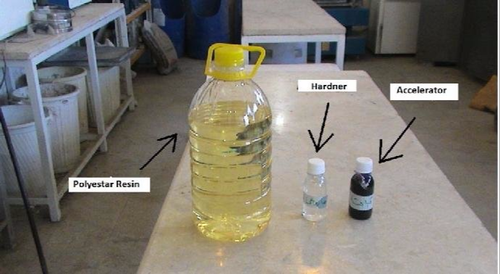

The polyester resin for gp is optimum if the laminate is entirely post cured. The volume of the Accelerator and catalyst must be wholly mixed before the catalyst is added to avoid a direct blending which may give rise to an explosion.

Storage and packaging:

The polyester resin remains stable for 4 months at 250C and 3 months at 300C in the dark. At an elevated temperature, the resin stability worsens, mainly when exposed to direct sunlight. 'No smoking' rules must be rigorously followed. In case of leakage, use earth or sand to absorb and spade off for disposal according to local regulations. And in the case of fire, use dry chemical foam, water spray, or carbon dioxide to extinguish the flame.

The polyester resin is packed using HDPE carboys ( 30, 35, 40, and 45 kgs) and HDPE drum barrels (225kgs) of standard net size and weight. Specific packing size provided for projects on returnable containers. Also, technical services are offered to comply with standards

Health and safe:

Never add accelerator metal salts or pre accelerated resin to peroxides while adding peroxides to a resin solution, and mix the resulting product thoroughly. In hot diluents or processes, make sure you do not add any organic peroxides. Prevent the impurities of Accelerator, a promoter from materials such as Copper, Iron, Cobalt storing acids, salts, and sanding dust. Recommended containers include polypropylene, glass, Teflon, stainless steel, or Poky-ethylene to prevent material's impurities during its handling.

What are the advantages of the unsaturated Polyester Resin:

Polyester resin for gp has a wide variety of features that are contemplated advantages to many applications that make them highly compliant to combine structures like fiberglass. Some of the advantages include:

· Due to the low viscosity benefit, it makes any compound easy to shape while laminating.

· It has a short curing time, i.e. (<12-24 hours )

· It gives excellent flexibility once it is cured. It makes it an incredible ingredient for combining structure like fiberglass

· Polyester can hold out against temperatures up to 80 degree Celsius

· The protraction capacity is ultimately good. When used in compounds, it produces a three times more flexible structure compared to carbon fiber.

· Good wetting is also another feature of polyester. It has good wetting to glass fibers, making the creation of new compounds easier

· During curing, it gives a comparatively low shrinkage rate at between 4-8 %. But the rate can be expected to lower under certain situations, ensuring excellent consistency in structural applications.

· Linear thermal extension ranges from 100-200 x 10-6 K-1

· Water-resistance capacity, cured polyester resin offers outstanding, extendable durability to water, having been utilized as a waterproofing system to protect various structures and used in the marine industry for boat construction.

· Polyester resin also offers broad chemical resistance to a range of components from vegetable oil to sulfuric acid, making it the popular resin choice in many coating and lining systems.

· Excellent chemical resistance capacity to aging and weathering

· Polyester resin holds out well against extreme weather conditions like ice. Snow, rain, and strong wind, as well as UV rays and high temperatures.

· Polyester resin is available at a comparatively low cost compared to other resins on the market by as much as five times.

What are the disadvantages of the Polyester Resin:

When compared to resin-based or resins, polyester resins do have some drawbacks that could be discerned as resin's limitations in certain circumstances; some of the disadvantages are as follows:

· It has lower mechanical properties when compared to epoxy resin, for example. On the other hand, unsaturated polyester resin for gp is more resilient but less rigid.

· Increased shrinkage is another factor though it can be minimized by adding thermoplastic components.

· It has a robust styrene smell, but with the possible effort, it can be reduced.

· Sufficient bubble-free mixing is required to ensure a qualitative laminate.

· No matter what resin it might be, safety is the primary concern. But this resin posses the toxic nature of its fumes, especially of its catalyst. MEKP constitutes a safety risk if the right protection is not used. And to mitigate these risks, flame retardant resin can also be utilized.

· Not suitable for bonding numerous substrates such as steel unless a primer is used

· Waste is also another disadvantage as many polyester resin-based compounds are sent to landfill every year, which is considerably increasing. But enough effort has been made to recycle it, from catalyst-driven recovery to the utilization of glycol degradation.

Conclusion:

All the information regarding polyester resin for gp is comprehensively discussed above, like its economic and straightforward use. It is considered a significant component in several industries, from aerospace to construction. It offers excellent physical and chemical properties and exclusively affordable compared to other resins like urethanes and epoxies. Also it gives superior performances in multiple cases.