Castellated Holes

💣 👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

Copyright 2016 PrototypePCB | All Rights Reserved

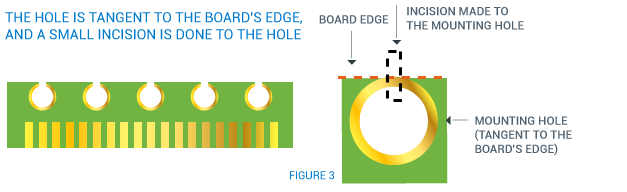

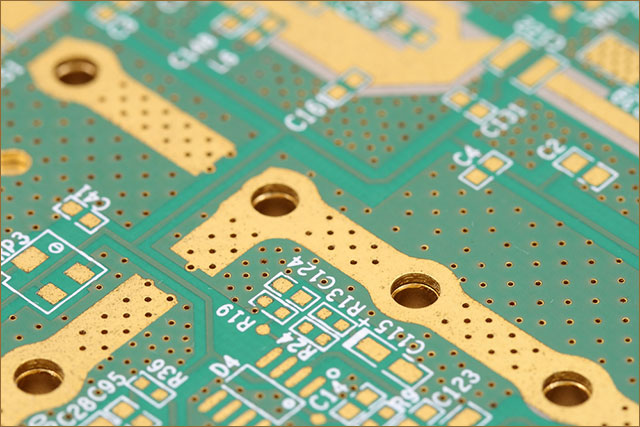

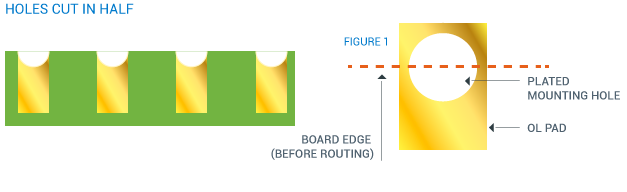

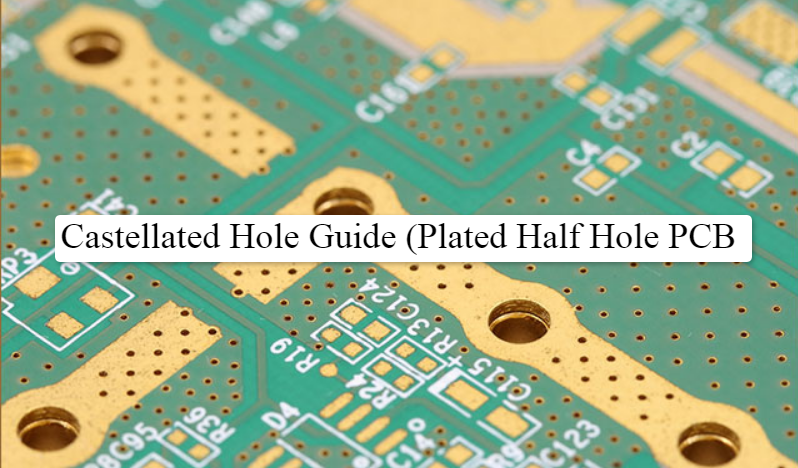

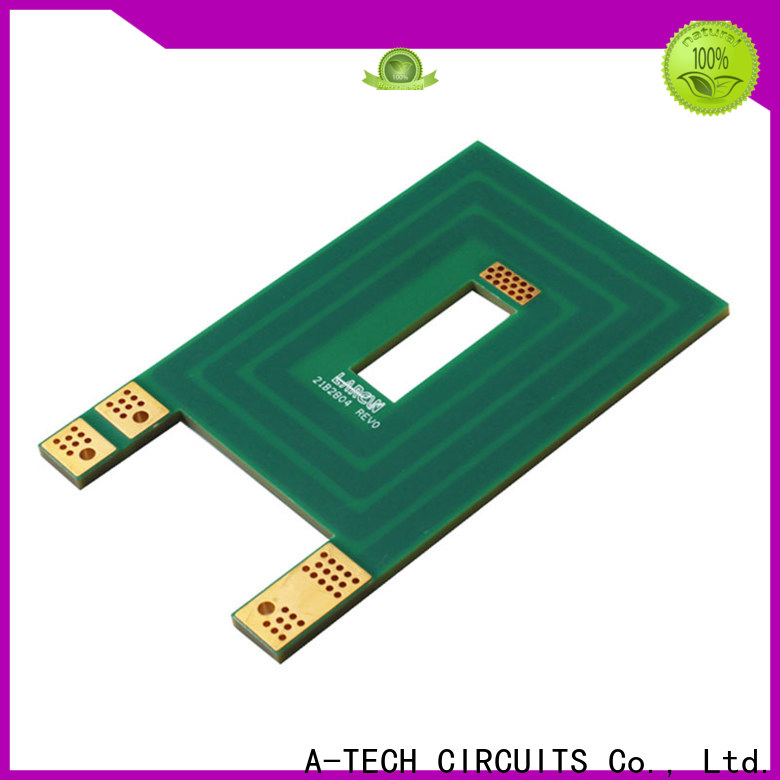

Castellated features are vias or thru holes that are cut through to create a partial or half hole for the purpose of creating an opening into the side of the hole barrel. These partial features are used for the purpose of mounting a PCB to another PCB by means of solder, or insertion of specially design edge connectors. There are multiple designs that constitute a feature that would fall under the castellation format.

There are several factors that contribute to the complexity of a castellated hole. The main critical design attributes are:

The hole size allows for a aplate breaka process to occur at the final fabrication operation. This post plate processing allows for more efficient removal of potential burring at the profile interface of the plated hole. This process may not be applicable to Type 2 parts depending on the dimensional requirements at the interface of the two holes.

Number of holes ensures that for any quantity of parts will have sufficient processing time, should any hand deburring activity be required.

Single hole feature allows better processing for the plate break process mentioned above. Type 2 parts may require additional hand deburr processing.

The size of the feature allows any surface finish to be used. As hole size decreases, a surface such as HASL becomes more difficult to process and the quality of the castellation may be affected.

The requirement for an outerlayer pad top and bottom ensures a 3-point wrap (top, side, and bottom) of the feature. This minimizes the possibility that the metal will peel away from the laminate.

Similar to Class I parts, except OL pad top and bottom are at or below the minimum .005a recommended.

Type 1, 3, & 4 parts have minimal concerns.

Type 2 parts may require additional hand finish rework to remove errant burrs. This is a result of the inability to utilize the plate break process properly due to the design used for this castellation style.

As hole size reaches the range above, the plate break process becomes less effective, thus resulting in added manual hand finish processing which is very time consuming.

HASL is not preferred, as the hole is difficult to efficiently clean of any burring and depending on the part design, may cause the hole barrel to become detached from the castellated feature.

If the design does not follow the recommended path of pads top and bottom, the metal may also become detached causing an improperly produced castellation.

When castellated features are required, it is best to use the following general rules when at all possible.

Sign Up

Sign In

Sign Up

Login

Solder Flux

Solder Paste

Solder Spheres

Solder Wire

What are Castellated Holes on a PCB?

EDI CON CHINA 2021

06 to 07 Sep, 2021

China

PCB WEST 2021

5 to 8 October, 2021

United States

SMTA INTERNATIONAL (SMTAI) 2021

01 to 04 Nov, 2021

United States

PCB Directory is the largest directory of PCB Manufacturers and Fabricators on Internet.

We have listed the leading Printed Circuit Board manufacturers around the world

and made them searchable by their capabilities - Laminates Used, Board Thickness

Supported, Layers supported etc.

Rigid PCB Manufacturers

Flexible PCB Manufacturers

Rigid-flex PCB Manufacturers

FR-4 PCB Manufacturers

Rogers PCB Manufacturers

RF PCB Manufacturers

High Tg PCB Manufacturers

USA PCB Manufacturers

Duroid PCB Manufacturers

Teflon PCB Manufacturers

2020 PCB Directory. All Rights Reserved.

The Largest Directory of PCB Manufacturers

Write an Answer

×

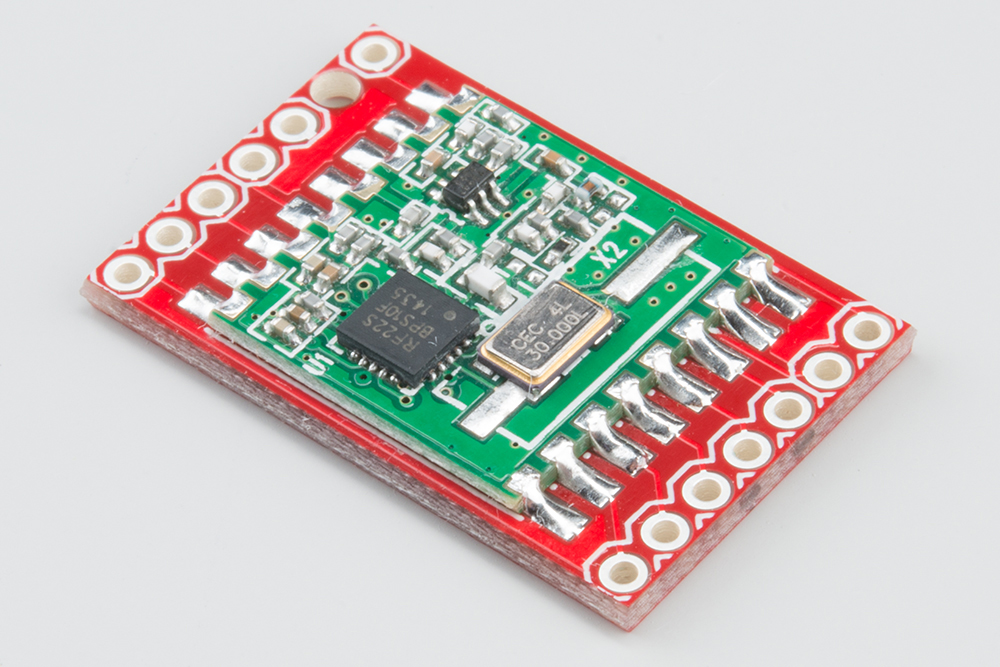

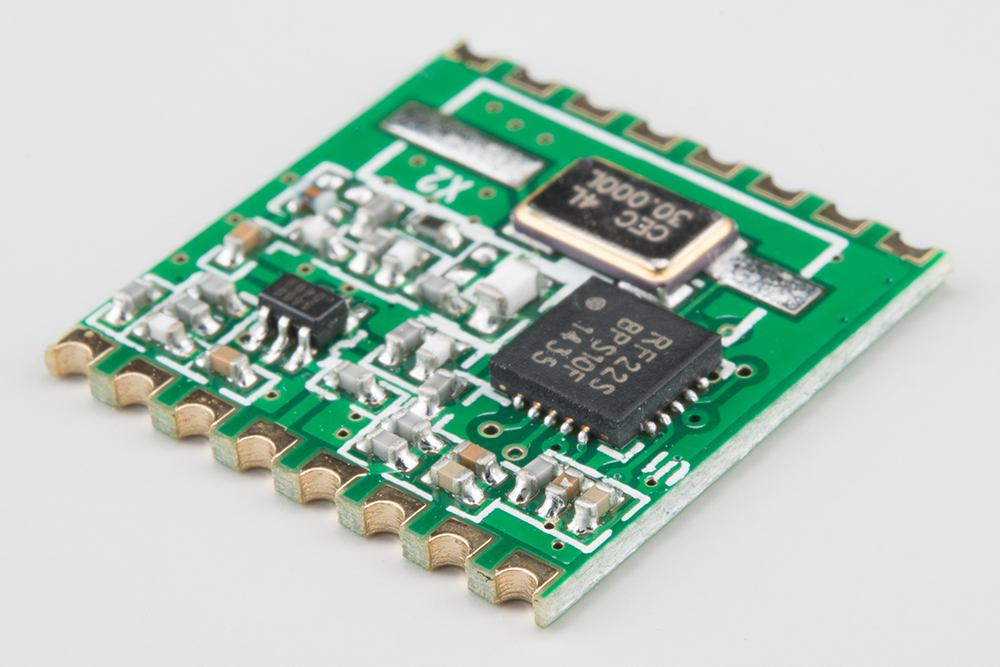

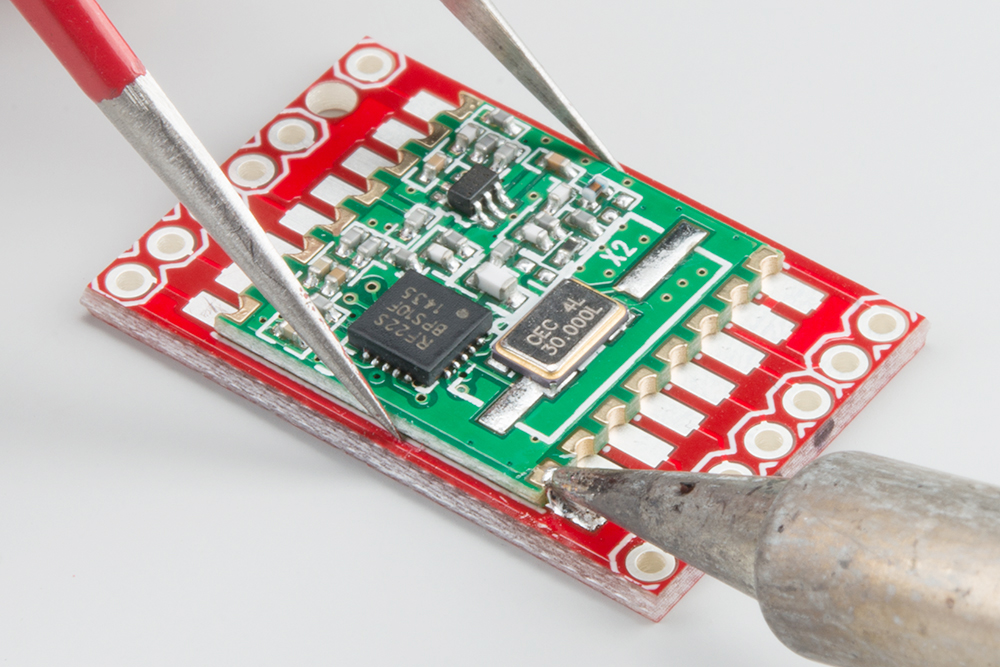

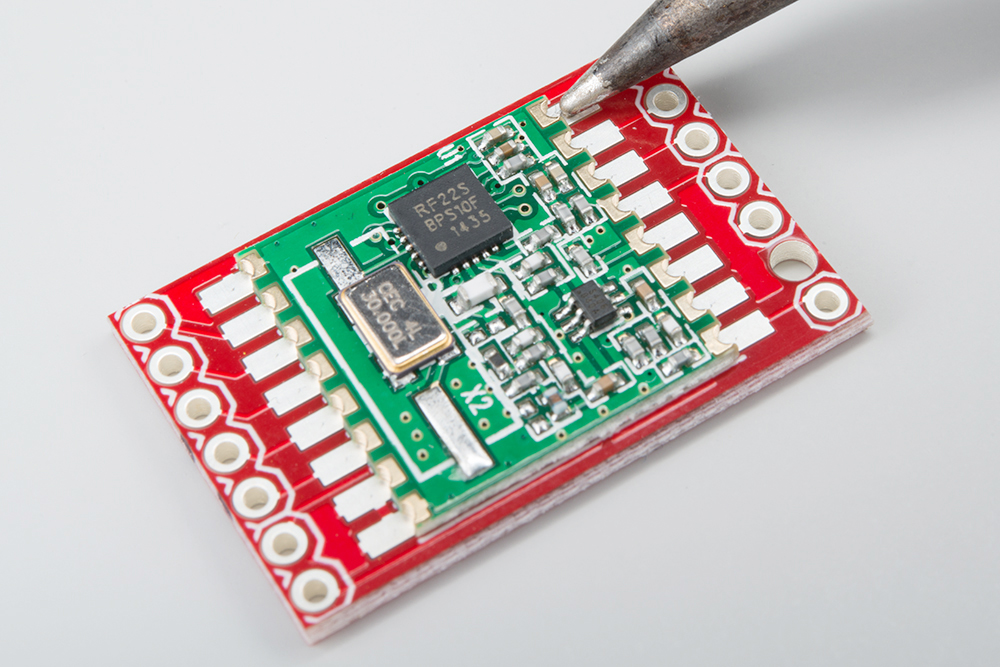

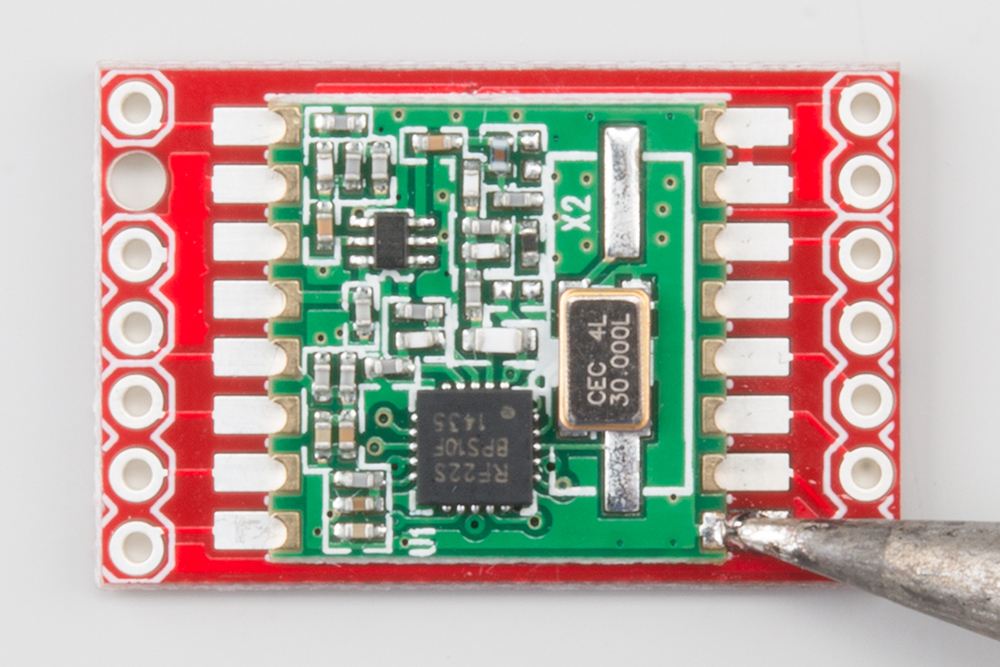

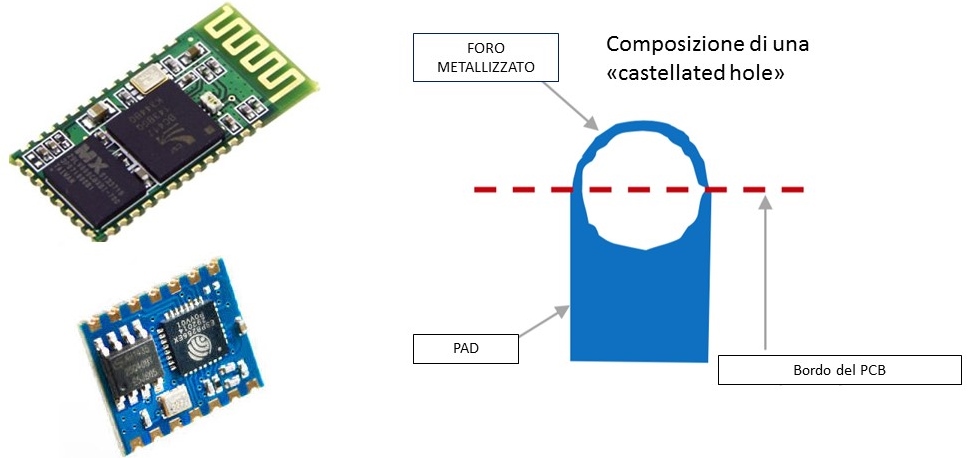

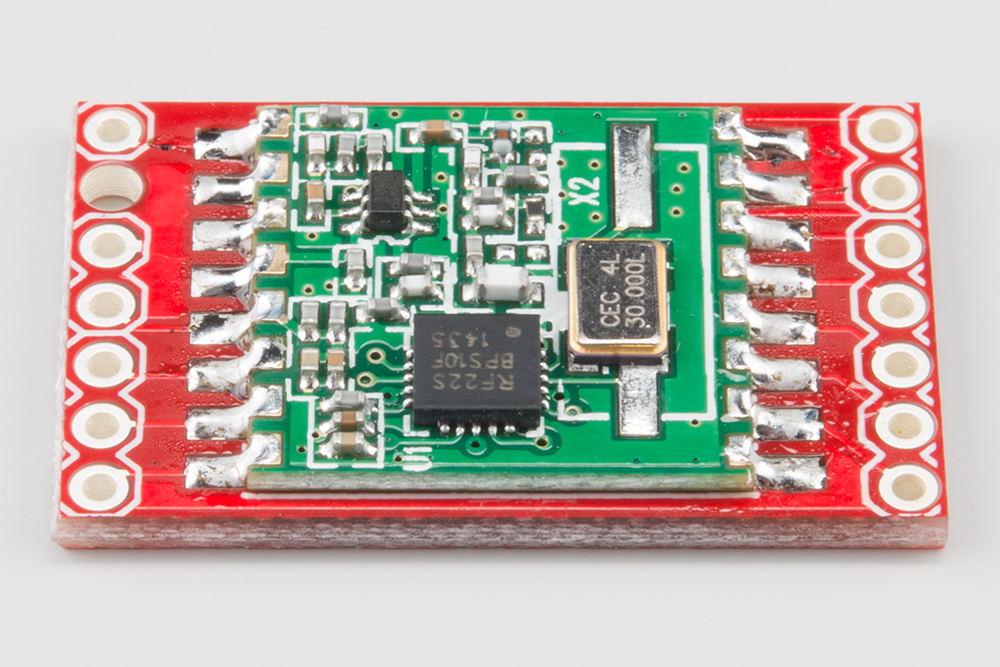

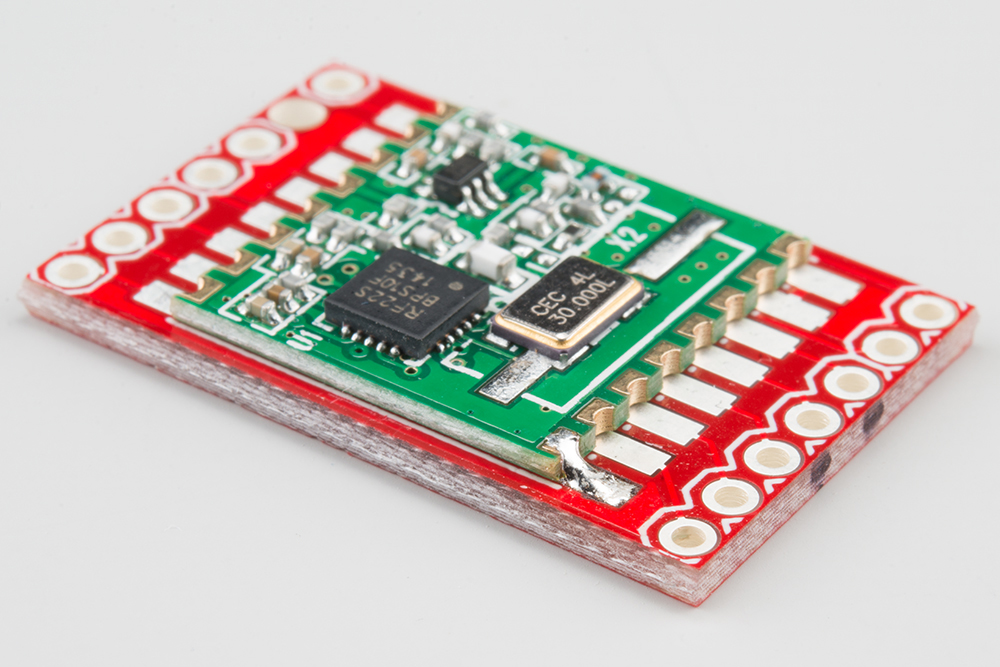

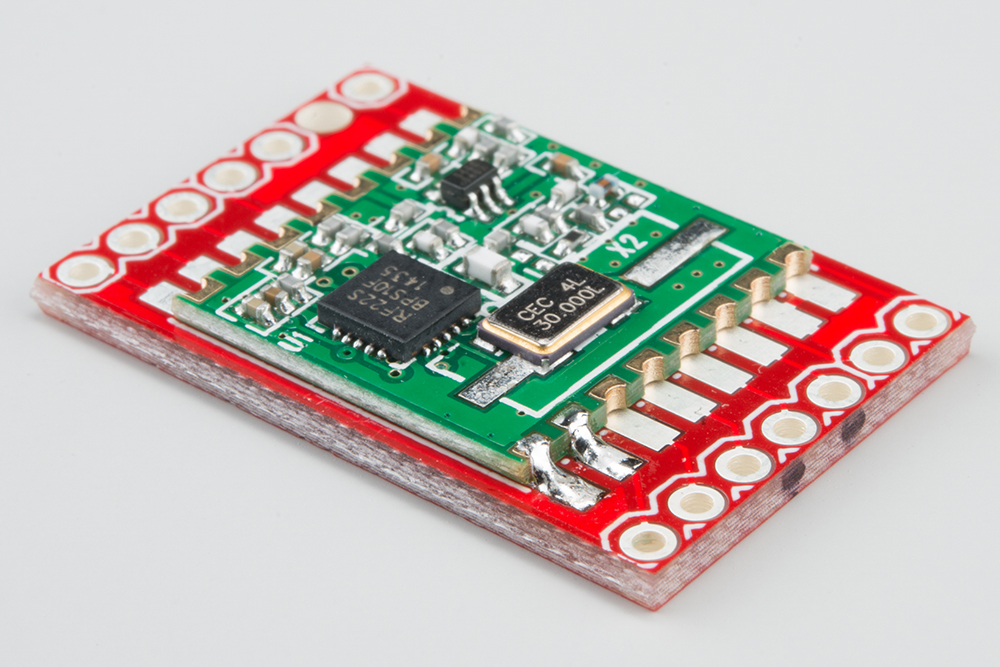

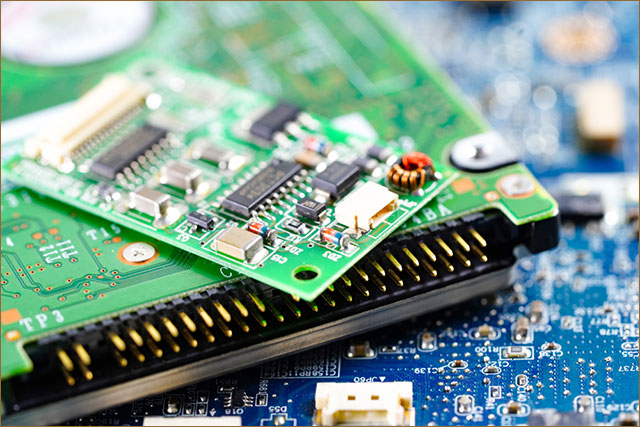

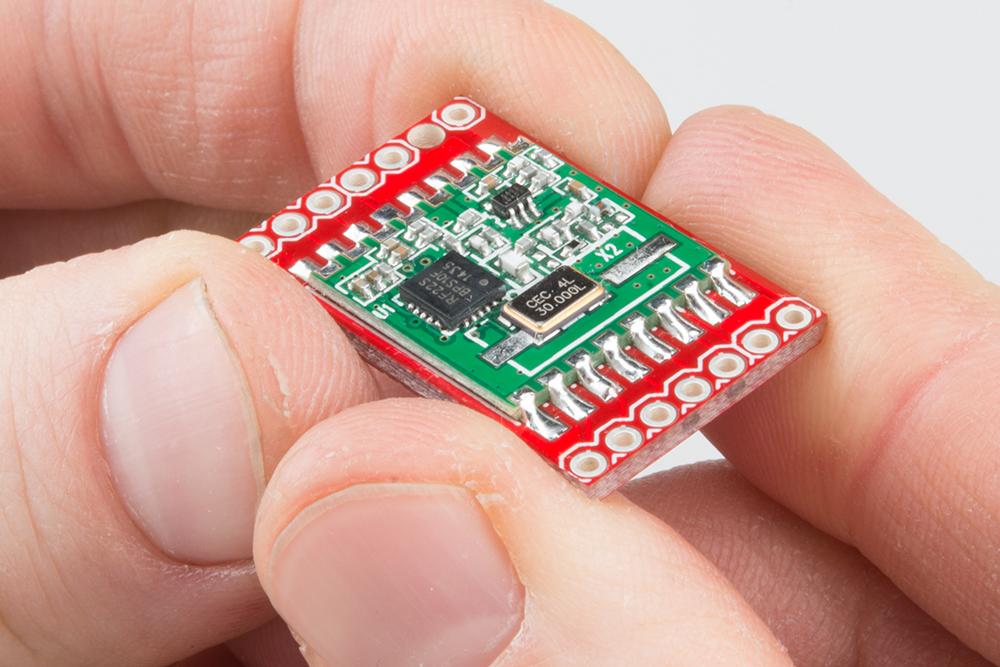

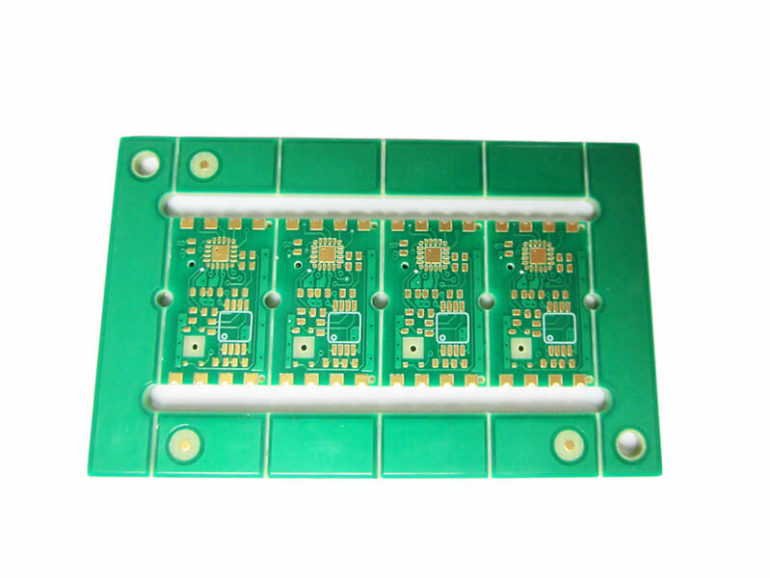

Castellated Holes or Castellations are indentations created in the form of semi-plated holes on the edges of the PCB boards. These Castellations help to mount one PCB board on top of another during assembly. Depending upon the application, instead of half holes, they may also look like a small or larger portion of a broken circle. Such holes are designed to provide proper alignment between the boards while soldering. This mounting process takes place with the help of castellated holes and called board-to-board soldering. Castellated holes are created on various PCB modules (Bluetooth or Wi-Fi modules), these modules can then be used as independent parts to be mounted onto another board during the assembly process.

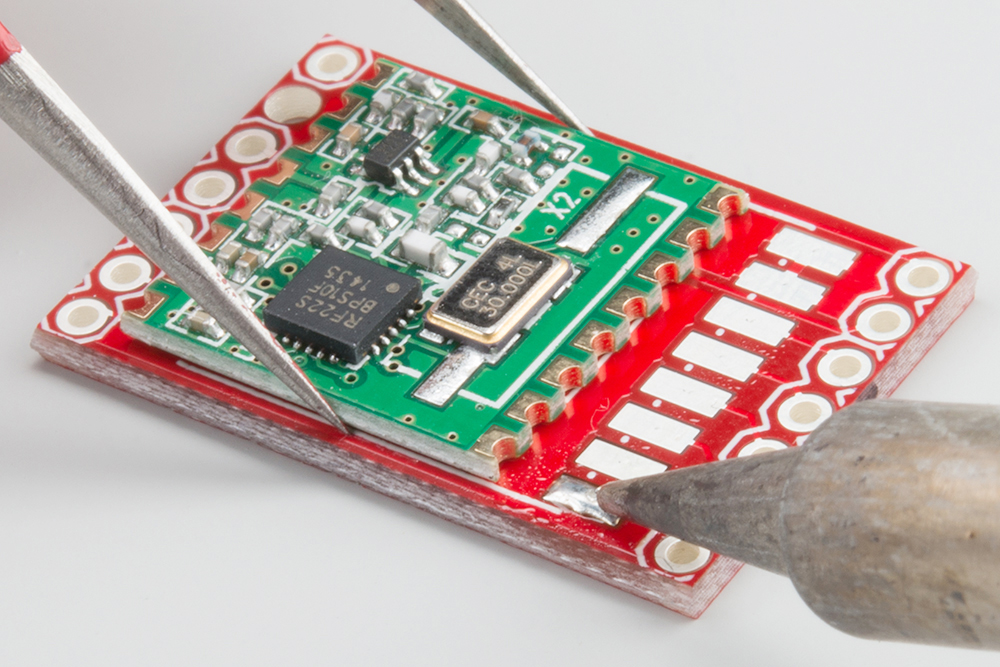

Through Hole Technology (THT) and Surface Mount Technology are commonly used during PCB assembly process. Apart from these, board-to-board soldering is used, when there is a need to mount a board on the top of another PCB. Castellations serve as a link between the module and the board onto which the module has to be soldered.

By creating these holes on the board edges, they can be used to replicate certain parts of a PCB circuit. For example, if there is a circuit that includes an inverter, filter, or feedback loops. These small sub-circuits can be mass-produced, tested and can be soldered on to the main PCB that contains other parts of the circuit whenever required.

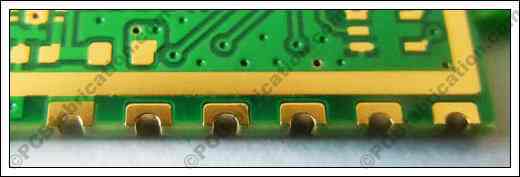

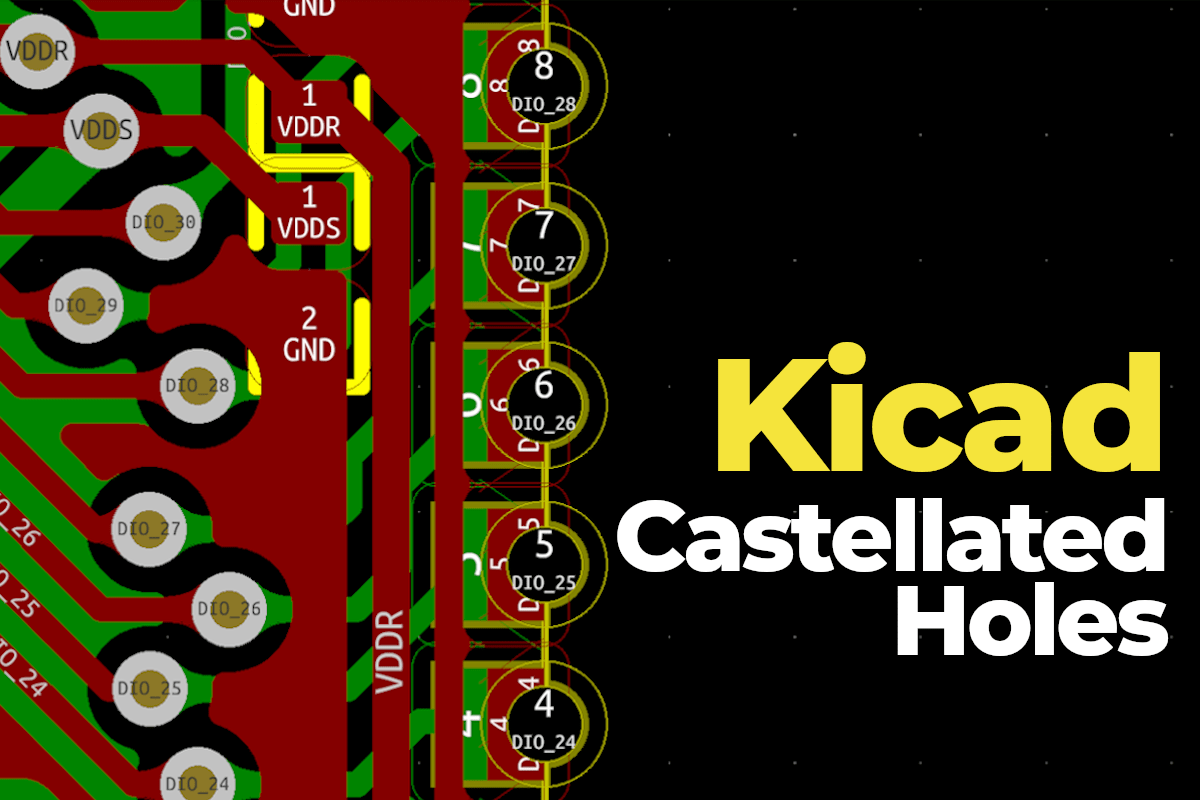

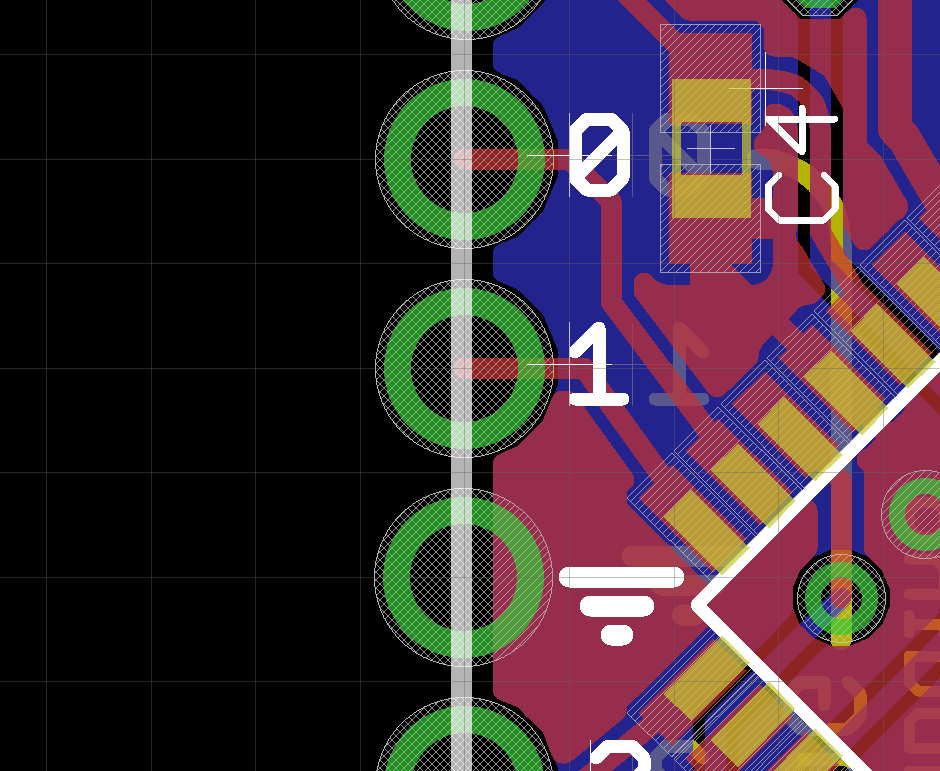

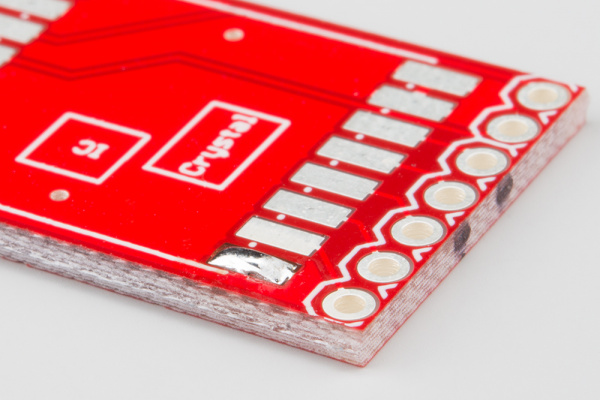

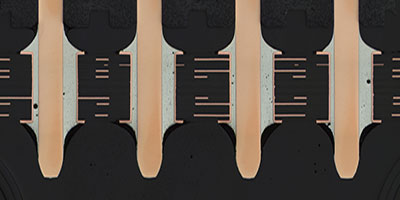

The castellated holes/ vias are created using a normal via process, which includes Drilling holes and copper plating. These holes look like semi-circles on the edges of the board since they are cut through to form a partial hole or half hole to create an opening on the board edges. Castellated holes can be created in various ways:

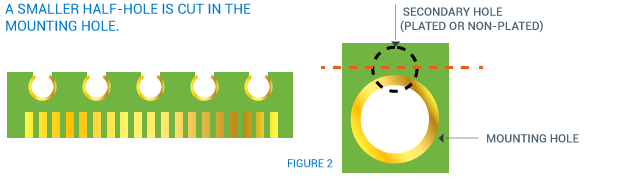

Holes with Smaller cut-in Half Holes

Holes with smaller lead-in holes for post-processing: They are designed for connector applications.

Recommended Specification for Castellated Holes

There are some design attributes for castellated holes to be followed:

Castellated holes on PCBs are used in a wide range of industries such as telecommunication, computer application, industrial control, power, automobile and high-end consumer electronics, and many more.

Circuit Technology Center has announced that it has expanded its Haverhill, Massachusetts facility by over 10,000 square feet... read more

https://prototypepcb.com/castellated-holes/

https://www.pcbdirectory.com/community/what-are-castellated-holes-on-a-pcb

Fist Fisting Porno

Cum Swap Sluts

Private Islands Online

Castellated Holes | Prototype PCB

What are Castellated Holes on a PCB? - PCB Directory

Castellated Holes | AISLER

Castellated PCB - Castellated Holes on a PCB - Its type ...

Castellated Holes - Bittele Electronics

How to Design Castellated Holes in a PCB for an SMD Module ...

Castellated Mounting Holes | PCB Fabrication | PCB ...

What are Plated Half-Holes/Castellated Holes? – Feedback ...

What Are Castellated Holes (PCB) ~ Information Guide Africa

Plated Half-Holes, Castellated PCB | Fuchuangke Technology

Castellated Holes