Cam Tube Bend

👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

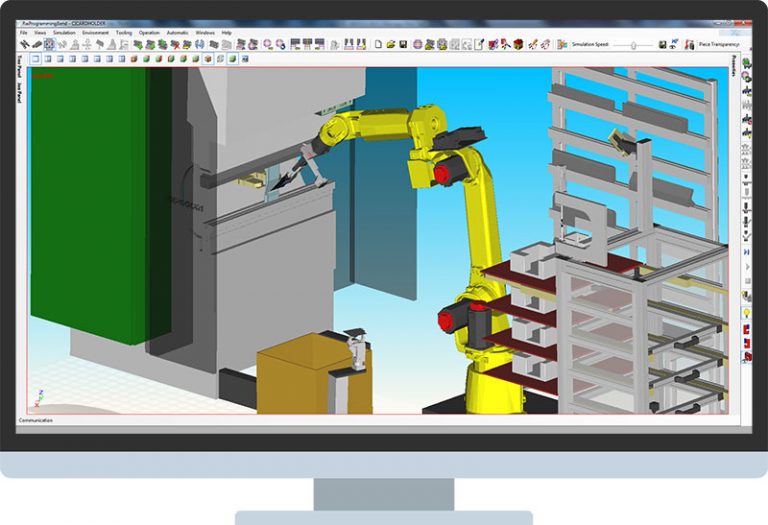

A new version of the TubeWorks tube bending CAD/CAM software, which now provides tubular metal fabricators with powerful pre-production tools for laser cutting as well as tube bending, is available from the tube bending machine manufacturer Unison.

Developed by the UK-based software consultancy 3DCompound, TubeWorks is a specialist add-in module for the popular SolidWorks mechanical CAD package. By combining powerful visualisation capabilities with automatic code extraction and file generation, the software enables metal fabricators to substantially increase the productivity of their tube handling operations through optimal use of manufacturing data. The time that it takes to develop programs for CNC tube bending and laser tube cutting machines, for example, is typically reduced from hours to just minutes.

Automatic extraction

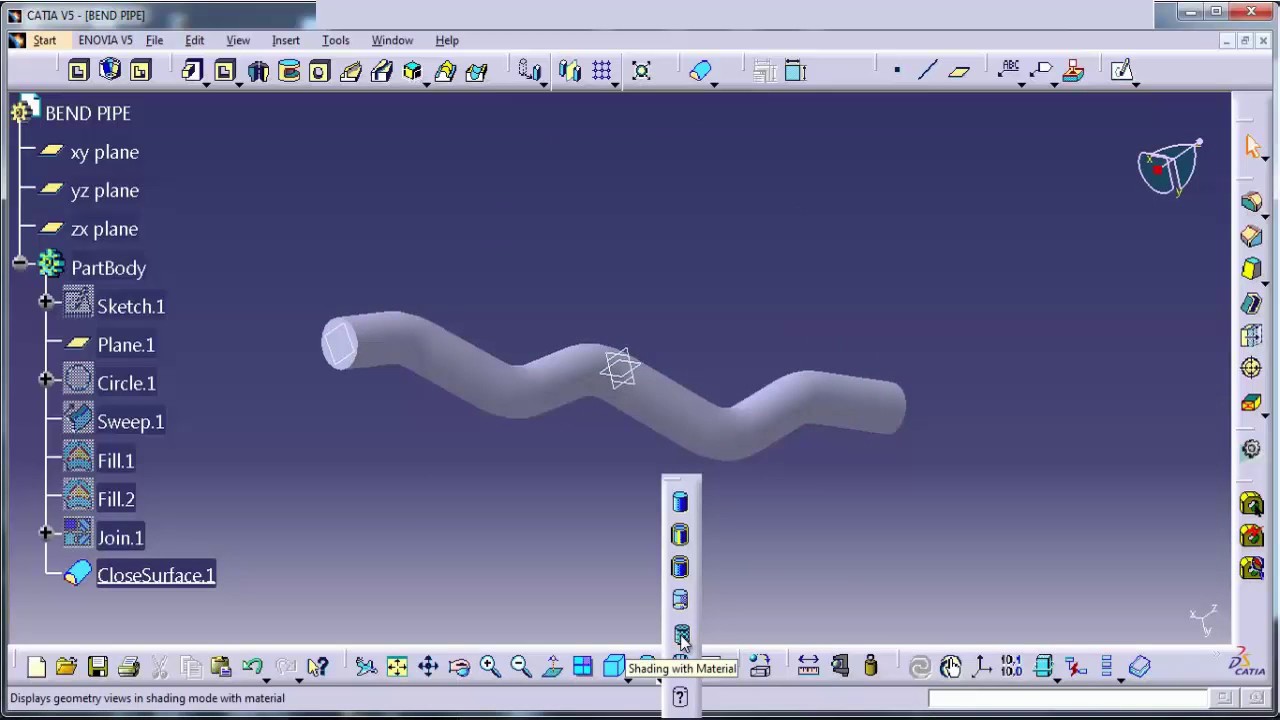

For tube bending, the software automatically extracts key manufacturing information such as bend angles and rotations from a native SolidWorks model or a common CAD file such as STEP, IGES or ParaSolid and creates the bend table for immediate use on a CNC bending machine, as well as the XYZ coordinates and a 2D drawing of the modelled tube. Version 2.6 of TubeWorks extends this functionality significantly, by enabling users to ‘unbend’ the CAD models of bent tubes into flat (or straight) configurations containing full details of all holes and cut-outs, to provide the input data for laser tube cutting machines.

Fully integrated

TubeWorks is a fully integrated add-in for the SolidWorks CAD package and is available exclusively from Unison. It eliminates the need for any additional software to generate manufacturing data for the design, development and production of tubular metal parts, while providing completely unfettered access to SolidWorks’ powerful design functions. A video demonstrating TubeWorks’ key features and ease of use can be viewed on Unison’s website at: http://unisonltd.com/products/software/tube-works/

Tube processing made easy

October 15, 2019

In "Laser micro-machining"

Current issue (E-mag) EN-FR-DE

Current issue (PDF) EN-FR-DE

Past issues (pdf)

Bulletin d’informations (E-MAG) WATCH & JEWELLERY

Bulletin d’informations (PDF) WATCH & JEWELLERY

Past issues (pdf)

Advertising – Service

Advertising – Machine-tools

Advertising – Lubrication

Advertising – Trade Show

Advertising – Machine-tools

Advertising – Machine-tools

Advertising – Cleaning

Advertising – Machine-tools

Advertising – Trade Show

Advertising – Machines

Advertising – Trade Show

Microtechnology community

Be informed as soon as we publish

RSS - Posts

Blog’s Archives by date

Blog’s Archives by date

Select Month

August 2021

July 2021

June 2021

May 2021

April 2021

March 2021

February 2021

January 2021

December 2020

November 2020

October 2020

September 2020

August 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

January 2020

December 2019

November 2019

October 2019

September 2019

August 2019

July 2019

June 2019

May 2019

April 2019

March 2019

February 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

November 2017

October 2017

September 2017

August 2017

July 2017

June 2017

May 2017

April 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

April 2016

March 2016

February 2016

January 2016

December 2015

November 2015

October 2015

September 2015

August 2015

July 2015

June 2015

May 2015

April 2015

March 2015

February 2015

January 2015

December 2014

November 2014

October 2014

September 2014

August 2014

July 2014

June 2014

May 2014

April 2014

March 2014

February 2014

January 2014

December 2013

November 2013

October 2013

September 2013

August 2013

July 2013

June 2013

May 2013

April 2013

March 2013

February 2013

January 2013

December 2012

November 2012

October 2012

September 2012

August 2012

July 2012

June 2012

May 2012

April 2012

March 2012

February 2012

January 2012

December 2011

November 2011

October 2011

September 2011

August 2011

July 2011

June 2011

May 2011

April 2011

March 2011

February 2011

January 2011

December 2010

November 2010

October 2010

September 2010

August 2010

July 2010

June 2010

May 2010

April 2010

March 2010

February 2010

January 2010

December 2009

November 2009

October 2009

September 2009

August 2009

July 2009

June 2009

May 2009

April 2009

March 2009

February 2009

January 2009

December 2008

November 2008

Blog’s Articles by field

Blog’s Articles by field

Select Category

3D printing

Additive manufacturing

Artificial intelligence

Assembly

Automation

Bar loading

Bonding

CAD/CAM

Clamping

Cleaning

Companies

Components

Control

Cybersecurity

Deep-drawing

Design

Economy

EDM

ERP

Events

General about Eurotec

Grinding

Hard turning

High Precision Machining

High precision turning

High speed machining

Honing

Hotel and experiences

Innovation

Jobs

Know-how

Laser micro-machining

Logistics

Lubrication

Machines

Machining

Marking

Material

Medical

MEM

Metrology

Micro Manufacturing

Milling

MIM

Molding

Motion

Moulding

Outillage

Peripherals

Plasma cutting

Plastic and composites

Poll

Product development

Rapid manufacturing

Robotics

Safety at work

Season’s Greetings

Services

Sheet metal

Sintering

Software

Special Resilience

Subcontracting

Surface technology

Sustainability

Swarf Management

Swiss Economy

The regions

Tooling

Trade show

Training

Transfer machines

Turning

Uncategorized

Watchmaking

Waterjet cutting

Welding

Werkzeuge

Pages

About us

Advertising

Articles

Cleaning

Companies/Clusters and Services

Complete issues

Control, Robotics, Software and CAM

Lubrication

Machining

Sub-contracting

Tooling, peripherals and components

Trade shows

Articles by companies

Best wishes for 2020

Best wishes for 2021

Bulletin d’informations Complete issues

Contact

De la sous-traitance mécanique à la métrologie de pointe : retour sur les 75 ans de Marcel Aubert

English/Français/Deutsch

Meilleurs voeux 2021

Newsletter

NGL bietet eine Reihe von Hochleistungsprodukten an, die an die Vorschriften angepasst sind

NGL, une gamme de nettoyage performante et adaptée à la réglementation

Plasturgy

PRIVACY POLICY STATEMENT

Provisional list of trade fairs 2021

Sondage janvier 2021

Special 60 years

Special 60 years

Subscription

Surface treatment

Survey January 2021

Topics

Editorial

Umfrage Januar 2021

Vom Unterlieferanten im Maschinenbaubereich zur Messtechnik der Spitzenklasse: Rückblick auf 75 Jahre Geschäftstätigkeit der Firma Marcel Aubert

What they think!

Metal fabricators who use SolidWorks CAD software can now accelerate the pre-production phase of tube bending by using a new add-in from Unison.

TubeWorks features a fully searchable tooling log that enables users to quickly check which bending tools will be needed for producing a part.

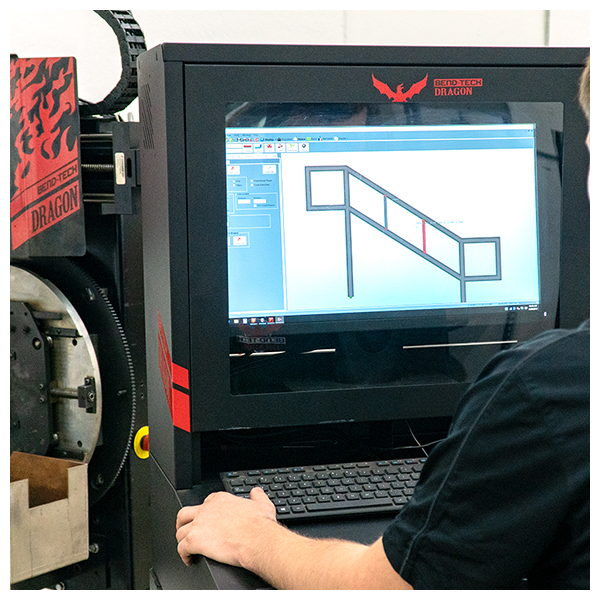

Unison tube bending machines are backed by software tools that enable users to quickly create production-ready programs.

Unison has launched a PC-based CAD/CAM product for tubular metal fabricators who use SolidWorks CAD software that, according to the company, enables them to reduce order processing and pre-production development time from hours to minutes.

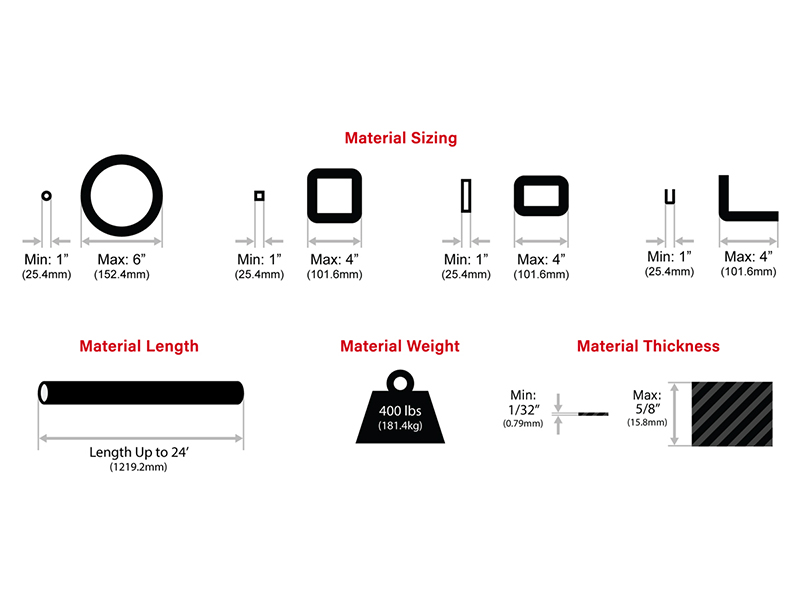

The software add-in, called TubeWorks, automatically extracts key manufacturing information, including tube specifications and CNC bending data, from both native SolidWorks models and common CAD file formats such as STEP, IGES and ParaSolid. It can handle tube models with round (tube and bar), square, rectangular, oval or flat-sided oval cross-sections.

Unison secured exclusive worldwide sales for TubeWorks from its developer, 3DCompound Ltd., a UK-based software consultancy that specializes in the development of third-party value-added products for SolidWorks. The company was founded by an accredited SolidWorks Elite Application Engineer with an extensive background in CAD and tube bending technology. It produces a variety of software tools, ranging from macros to fully integrated add-in modules.

According to Alan Pickering, Managing Director of Unison, "Automating the extraction of manufacturing data from CAD files helps bending machine users to create production-ready programs much more quickly and efficiently. TubeWorks will provide our customers with an enormous competitive advantage and is an important addition to our growing portfolio of software tools. As well as offering a smart solution for metal fabricators seeking to accelerate their request-for-quotation (RFQ) procedures, the software will help companies with in-house bending machines to reduce design-to-manufacturing times."

3DCompound's Managing Director Ali Jani said, "We chose Unison as a partner because its innovative culture matches well with our own. Unison's all-electric tube bending machines are widely regarded as some of the best in the industry, enabling companies to push performance boundaries in metal tube fabrication. Our new TubeWorks add-in is designed with the same principles and for the same markets. We believe that the software provides users with a unique and powerful means of enhancing the productivity of their tube bending operations."

"The TubeWorks add-in is fully integrated into SolidWorks, allowing users to take full advantage of the CAD software's powerful design functions, and eliminates the need for any additional standalone solutions for generating manufacturing data during the design, development and production of tubular parts," said a company spokesperson. "The add-in software is inherently intuitive and easy to use, requires no special training and can be mastered within 10 minutes."

In addition to its manufacturing data extraction capabilities, TubeWorks offers a variety of functions to further help users minimize the pre-production design time of machine-based tube bending. These include automated centerline creation through tubular geometry (for both round and non-round profiles) and automated conversion of imported tube models into native SolidWorks models for CLR (centerline radius) modification. The software also extensively automates the generation of 2D drawings, as well as the creation of reports for the YBC data that will be used to control the bending machine and for the XYZ coordinates of the modeled tube.

To help maximize flexibility and ease of use, TubeWorks is fully functional in a multi-body part environment. A searchable tooling log enables users to quickly check the types of tools - such as bend former, mandrels, wiper dies, etc. - that will be necessary for a particular bending operation, while a tooling recommendation function verifies whether a part can be produced using existing tools, or suggests suitable substitutes. The software also includes a tube length calculator, which evaluates the total length of tube that will be needed for fabricating the specific formed part.

Manufacturing News is a monthly metalworking manufacturing publication that informs over 100,000 monthly readers of manufacturing solutions and new technology and the application of that technology in precision machining, production machining, fabricating of metals and composite materials. We welcome news releases that fit our editorial profile. The manufacturing we write about is the machining or fabricating that results in the creation of components, i.e., the manufacturing of discrete parts.

Gross Publications, Inc.

1133 Airline Drive, Suite 2100

Grapevine, Texas 76051

USA

Phone: 817-488-8488

Fax: 817-488-7813

Email: info@mfgnewsweb.com

© Gross Publications, Inc.

Follow us online:

Naked Israel Women Beautiful

Baby Legs Spread Ru

Covered Cum Wife

Big Ass Twerk Compilation

Mila Kunis Leaked Naked Pictures

CAD/CAM Software for Tube Bending and Laser Tube Cuttin…

Tube Bending CAD/CAM Software - mfgnewsweb.com

See Bend Live Webcams & Weather Report in Oregon ... - …

Bend Cutting - Metalix CAD/CAM Sheet Metal Software

CAD/CAM | Software | Sheet Metal Processing | Products|A…

Dural Bend - Tube and Pipe Bending Machines

Tube and pipe basics: How to achieve the perfect bend

Cam Tube Bend