CNC Machined Plastic Prototypes and Low Volume Parts Can Be Fun For Anyone

The Definitive Guide to Fixturing and Routing of Plastics with CNC - LMT Onsrud

Disadvantages, Nylon 6/6 will absorb wetness, triggering it to swell and lose some dimensional accuracy. It can also warp if there is a big amount of asymmetric product removal throughout machining, due to internal tensions intrinsic in the material. Typical Applications, Nylon is most typically found in medical gadgets, circuit board mounting hardware, vehicle engine compartment parts, and zip ties.

CNC Milling Services California

CNC Milling Services CaliforniaAcrylic, Summary, Acrylic, also known as Plexiglass or Luctie, is the trade name for PMMA plastic. It is difficult, with good impact strength and scratch resistance, and can be easily glued using acrylic cement. Also Found Here , It is well fit for any applications that need optical transparency or transparency, or as a less resilient but cheaper alternative to polycarbonate.

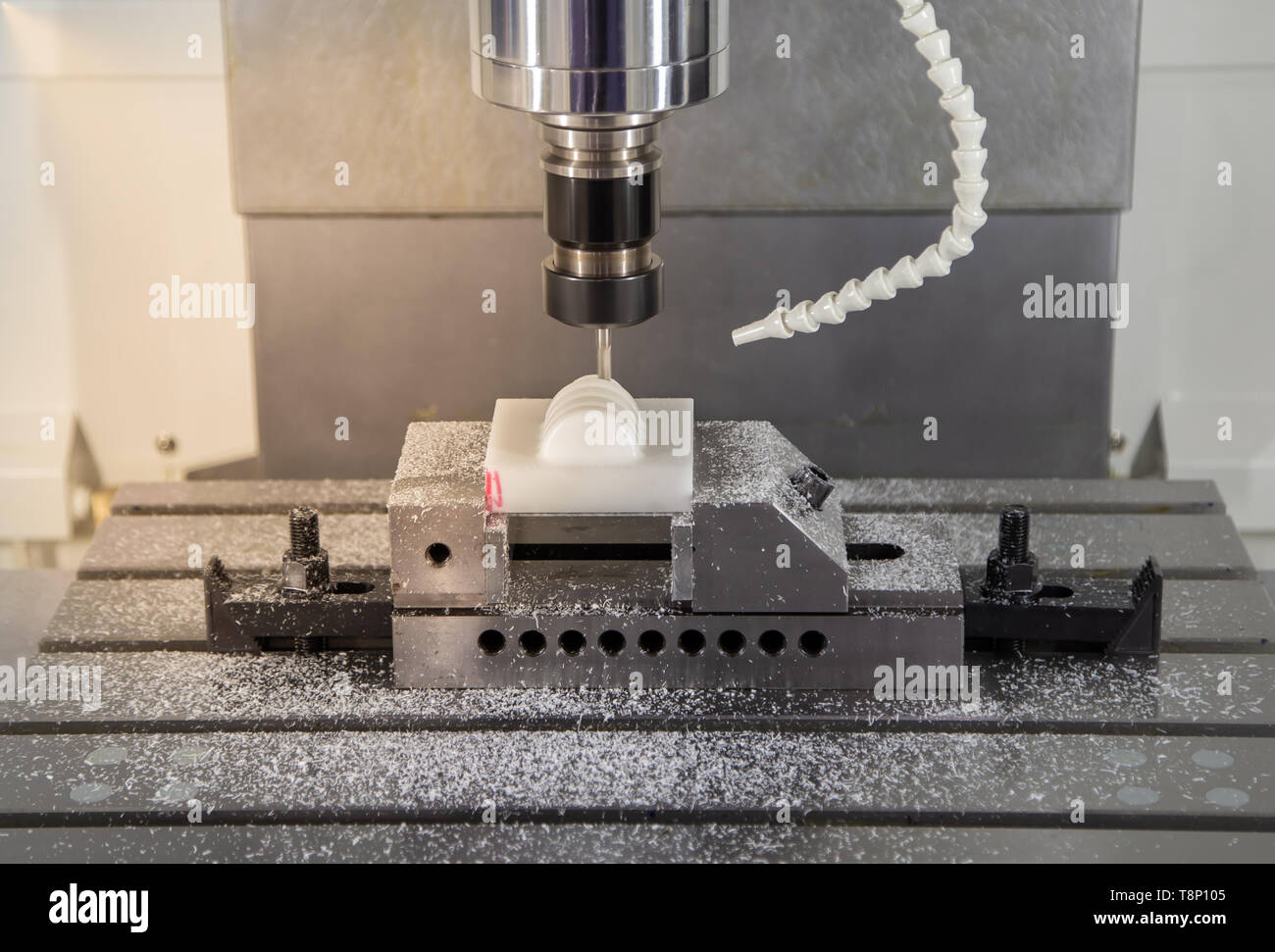

Any machined surface areas on a piece of acrylic will lose their openness and take on a frosted, translucent appearance. Due to the fact that of this, is it normally a great concept to keep in mind if an acrylic part needs to be left at stock thickness to preserve openness or not. If transparency is required on a machined surface area, it can be polished as an extra post processing action.

Delrin, Overview, Delrin is a particular brand of acetal homopolymer (aka POM). It has a slippery, low friction surface, exceptional dimensional stability, and high tightness. Advantages, Delrin is a good plastic for these or any other applications that will experience lots of friction, require tight tolerances, or need a high stiffness material.

The Best Guide To Custom CNC Machining and Plastic Fabrication from ePlastics

The material also has internal tensions that make it prone to deforming in areas that are thin or have big amounts of asymmetric material elimination. Common Applications, Delrin is typically utilized in equipments, bearings, bushings, and fasteners, or to make jigs and fixtures for assembly. HDPEOverview, HDPE means high density polyethylene.

It is well matched for making plugs and seals, due to its chemical resistance and slipperiness, but is likewise a good option for weight-sensitive or electrically delicate applications. Downsides, HDPE's main drawback it its poor strength, particularly in stress and flexing. Common Applications, HDPE is frequently utilized in fluid applications, such as fuel tanks, plastic bottles, and fluid flow pipes.