Build Your Own CNC Machine by Patrick Hood Daniel and Things To Know Before You Buy

Inexpensive Cnc Projects : Build Your Own Cnc Machine, Paperback by Davis, Ro 9781500328139 - eBay

Inexpensive Cnc Projects : Build Your Own Cnc Machine, Paperback by Davis, Ro 9781500328139 - eBay4 Easy Facts About Build Your Own CNC Machine by James Floyd - CircuitMix Described

no longer supports Web Explorer. To browse Academia. edu and the wider web faster and more firmly, please take a couple of seconds to update your browser.

DIY 80/20 Aluminum Extrusion CNC Machine - 8020CNC.com

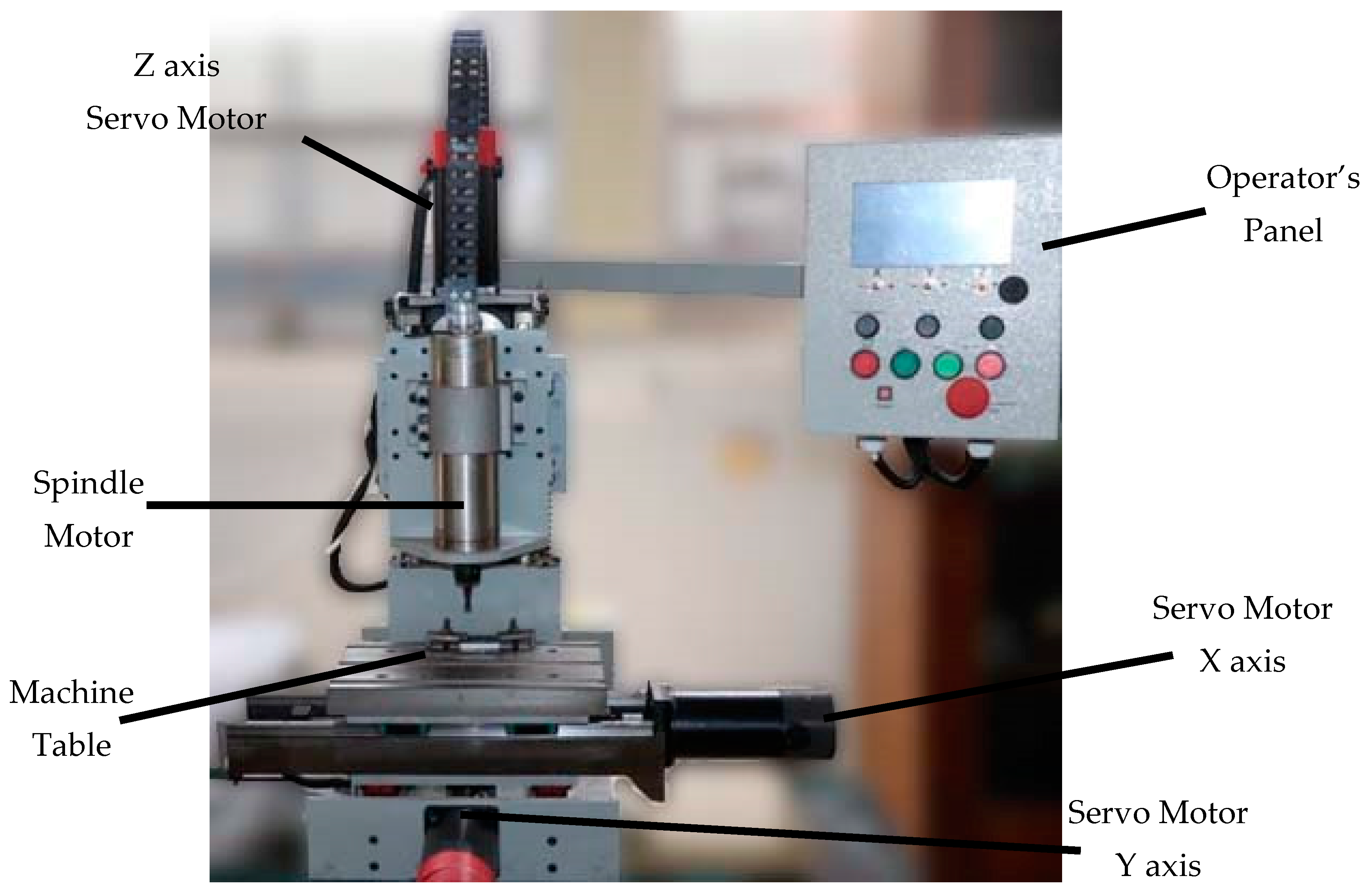

DIY 80/20 Aluminum Extrusion CNC Machine - 8020CNC.comDepending on the number of corners you cut with the DIY CNC Router, and how fancy your CNC Mill project is, a CNC Mill is probably the most costly, hardest to do, however a lot of flexible do it yourself CNC Device. While there have actually been some scratch-built CNC Milling makers done, you're best off converting a manual milling maker to CNC up until you have a lot of CNC experience under your belt.

There are a great deal of possibilities. Some to think about in order of heaviest/most expensive to lightest/cheapest consist of: Bridgeport-style Knee Mill: These are expensive, and the heavy knee is not specifically well suited to CNC. OTOH, there are a lot of CNC 'd knee mills out there and nothing says, "Milling Machine" like a Bridgeport.

The Main Principles Of Linuxcnc driver boards - AlfikrahRF-45 and Clones: These are Chinese-made Bed Mills that are readily available from all sorts of places and in all sorts of variations. They have a work envelope and rigidness similar to a Bridgeport, but without the heavy knee, so they're much better fit to CNC tasks. Their biggest downside is their spindle, which is restricted to 1600 rpm.

How to Make a Three Axis CNC Machine (Cheaply and Easily) : 12 Steps (with Pictures) - Instructables

How to Make a Three Axis CNC Machine (Cheaply and Easily) : 12 Steps (with Pictures) - InstructablesGrizzly G0704: These mills are a little smaller sized than an RF-45, however they are a perfect CNC platform. Folks like Hoss at Hossmachine can supply complete details of whatever you need to understand, plans, and frequently sets to aid with conversions. If the table and journeys are big enough for your tasks, this will be a cheaper and faster job than an RF-45.

I don't believe I 'd go any smaller than the X2, however you can do some incredible things with one as Hossmachine has shown (full automated tool changer and VMC design enclosure). Here's a fantastic article on picking a donor device for your DIY CNC Mill Job. An important note: Some beginners begin considering transforming a drill press to a milling machine.

The Best Guide To Building Your Own Cnc Milling Machine (1) - ID:5c12270de44e8It will require a lot effort to produce an average result that it just isn't worth it. Here are A Reliable Source : My DIY RF-45 Mill Conversion Hoss's G0704 CNC Conversion at a relatively early phase: he added a lot more!.