Boring Holes

💣 👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

Afghanistan Algeria Angola Anguilla Antigua and Barbuda Argentina Armenia Aruba Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bermuda Bhutan Bolivia Bosnia and Herzegovina Botswana Brazil Brunei Darussalam Bulgaria Cambodia Cameroon Canada Cayman Islands Central African Republic Chad Chile China Colombia Costa Rica Croatia Cuba Cyprus Czech Republic Denmark Dominica Dominican Republic Ecuador Egypt El Salvador Estonia Ethiopia Finland France French Guiana Gabon Georgia Germany Ghana Greece Grenada Guadeloupa Guatemala Guyana Haiti Honduras Hong Kong Hungary Iceland India Indonesia Iran Iraq Ireland Israel Italy Ivory Coast Jamaica Japan Jordan Kazakhstan Kenya Korea (South) Kuwait Laos Latvia Lebanon Lesotho Libya Lithuania Luxembourg Macedonia Malawi Malaysia Malta Martinique Mauritania Mexico Moldova Montenegro Montserrat Morocco Mozambique Namibia Nepal Netherlands New Caledonia New Zealand Nicaragua Nigeria Norway Oman Pakistan Panama Paraguay Peru Philippines Poland Portugal Qatar Republic of Congo Romania Russia Saint Kitts and Nevis Saint Lucia Saint Vincent and the Grenadines Saudi Arabia Senegal Serbia Singapore Slovak Republic Slovenia South Africa South Sudan Spain Sri Lanka Sudan Suriname Swaziland Sweden Switzerland Syria Taiwan Tanzania Thailand Togo Trinidad and Tobago Tunisia Turkey Turkmenistan Turks and Caicos Islands Ukraine United Arab Emirates United Kingdom United States Uruguay Uzbekistan Venezuela Vietnam Virgin Islands (British) Yemen Zambia Zimbabwe

Česky Dansk Deutsch English English (US) Español Français Italiano Magyar Nederlands Polski Português Suomi Svenska Türkçe Русский ไทย 한국어 中文 日本語

Based on your preferences, we have established the following country settings.

United Kingdom-English

GB-EN

Settings

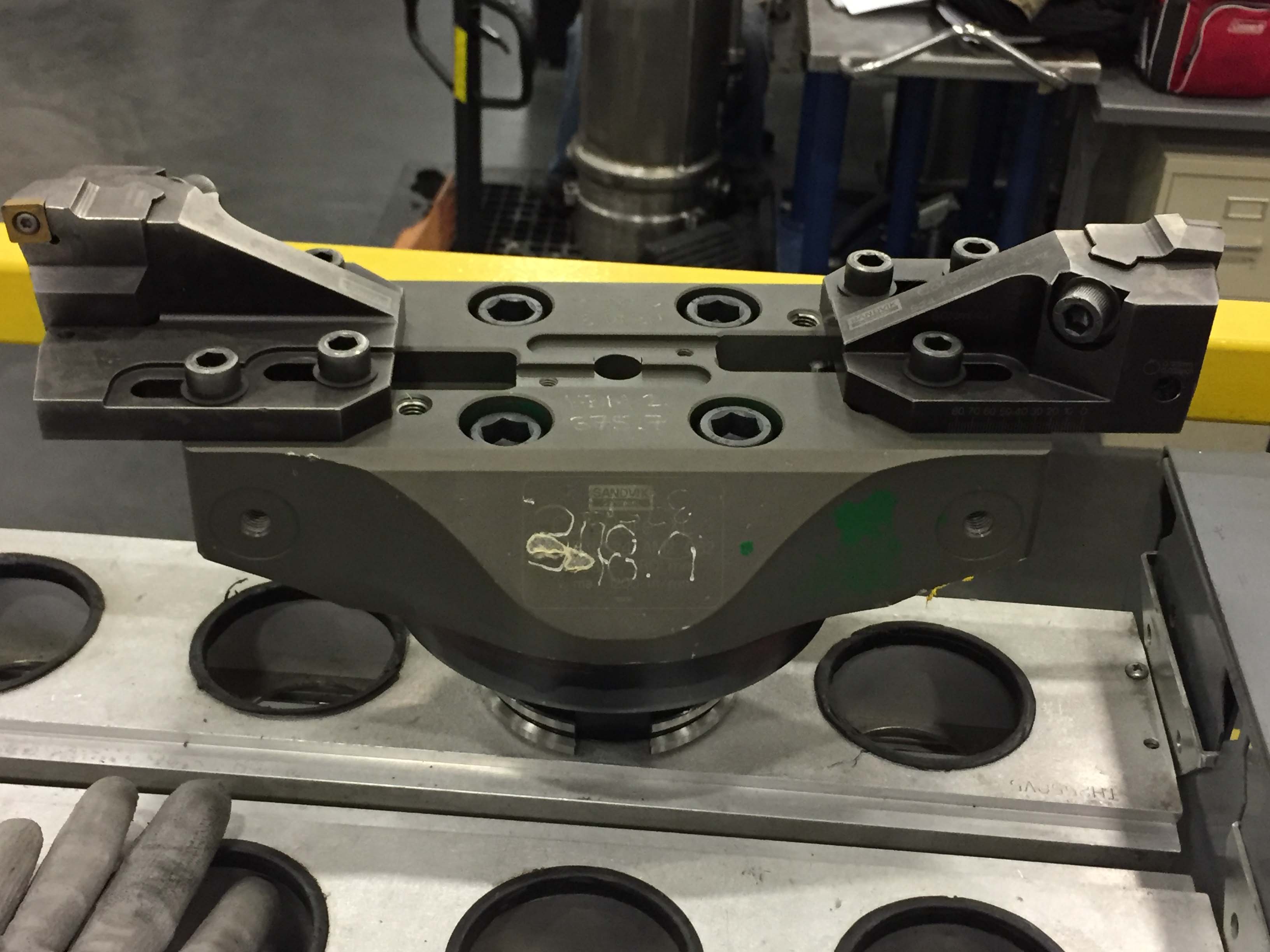

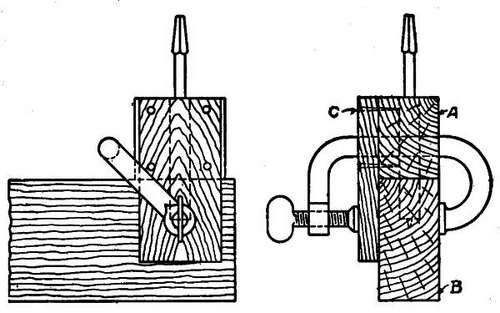

Boring is a machining process for enlarging or improving the quality of an existing hole. When boring holes, there are several flexible tool systems available in a wide diameter range for both rough and fine boring.

These initial considerations will affect the choice of boring tools and how they are applied when boring holes.

The quality of the hole affects the type of operation and choice of tool.

Consider the hole dimension, limitations and quality demands:

Identify the type of operation, roughing or finishing:

Machining of an existing hole with focus on metal removal in order to prepare for finishing. The existing holes are made by methods such as drilling, casting, forging and flame cutting. For hole tolerances larger or equal to IT9.

Machining of an existing hole to achieve a close hole tolerance and high quality surface finish. Small cutting depths, generally below 0.5 mm (0.020 inch). For hole tolerances between IT6 and IT8.

Identify what type of component to work with.

Register for our free e-learning programme

Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing. Sandvik Coromant owns over 1,700 patents worldwide, employs over 7,700 staff, and is represented in 150 countries.

Česky Dansk Deutsch English English (US) Español Français Italiano Magyar Nederlands Polski Português Suomi Svenska Türkçe Русский ไทย 한국어 中文 日本語

United Kingdom-English

GB-EN

Settings

Boring is a machining process for enlarging or improving the quality of an existing hole. When boring holes, there are several flexible tool systems available in a wide diameter range for both rough and fine boring.

These initial considerations will affect the choice of boring tools and how they are applied when boring holes.

The quality of the hole affects the type of operation and choice of tool.

Consider the hole dimension, limitations and quality demands:

Identify the type of operation, roughing or finishing:

Machining of an existing hole with focus on metal removal in order to prepare for finishing. The existing holes are made by methods such as drilling, casting, forging and flame cutting. For hole tolerances larger or equal to IT9.

Machining of an existing hole to achieve a close hole tolerance and high quality surface finish. Small cutting depths, generally below 0.5 mm (0.020 inch). For hole tolerances between IT6 and IT8.

Identify what type of component to work with.

Register for our free e-learning programme

Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing. Sandvik Coromant owns over 1,700 patents worldwide, employs over 7,700 staff, and is represented in 150 countries.

https://www.sandvik.coromant.com/en-gb/knowledge/boring/pages/default.aspx

https://www.sandvik.coromant.com/en-gb/knowledge/boring/Pages/default.aspx?nodeid=899

Step Daughter Pov Porno

Jennifer Lopez Booty Mp3

Muslim Girl Pray Porn

Boring holes - Sandvik Coromant

Boring holes - Sandvik Coromant

Boring (manufacturing) - Wikipedia

Boring 101 - A Guide To Everything Boring – Rigibore

Difference Between Drilling, Boring & Reaming - Cargister

6 DIFFERENT METHODS OF BORING USED FOR SOIL …

I want a borehole on my property as a source of drinking ...

Kola Superdeep Borehole - Wikipedia

Bore hole water

Boring Holes