Beyond the Great Wall: Understanding the China Plus One Strategy

In recent years, the global manufacturing landscape has experienced significant shifts, prompting many companies to rethink their operational strategies. One of the most noteworthy approaches that has emerged is the China Plus One strategy. This concept seeks to diversify supply chains beyond the traditional reliance on China, acknowledging both the opportunities and risks inherent in sourcing from a single country. As businesses face challenges such as rising labor costs, geopolitical tensions, and disruptions caused by events like the pandemic, the need for a more resilient and flexible approach has become evident.

The China Plus One strategy encourages companies to establish alternative manufacturing locations while maintaining a presence in China. By doing so, organizations can mitigate risks associated with overdependence on a single market, tap into new opportunities, and enhance their competitive edge. This strategy not only aims to safeguard supply chains but also allows companies to better respond to the ever-changing global economic landscape. Understanding this approach is crucial for businesses looking to thrive in the current environment, as it represents a proactive response to both challenges and possibilities in international trade and manufacturing.

Overview of the China Plus One Strategy

The China Plus One strategy refers to a business approach adopted by companies seeking to diversify their supply chains beyond China. This strategy has gained significant traction as global companies recognize the risks associated with relying heavily on a single country for manufacturing and production. By adding an additional country to their supply chain portfolio, businesses aim to mitigate risks such as geopolitical tensions, trade disputes, and sudden disruptions caused by unforeseen events like the COVID-19 pandemic.

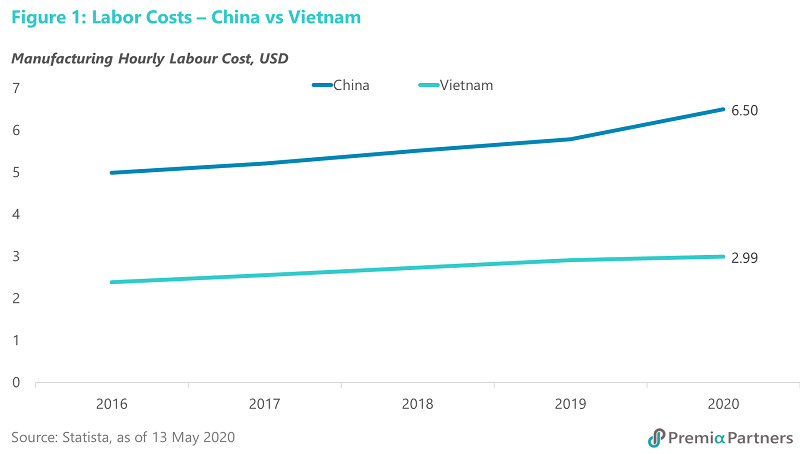

In implementing the China Plus One strategy, companies often look to establish operations in countries that offer competitive advantages such as lower labor costs, favorable trade agreements, or proximity to key markets. Southeast Asian nations like Vietnam, Thailand, and Indonesia have emerged as popular alternatives, providing a combination of cost efficiency and the ability to scale production quickly. The shift not only helps companies maintain supply chain resilience but can also lead to new market opportunities in emerging economies.

As firms adapt to the China Plus One strategy, they must carefully evaluate various factors, including logistics, political stability, and the business environment in potential countries. This strategic shift represents a significant change in the global manufacturing landscape, prompting companies to innovate and rethink their operational models to stay competitive in an increasingly interconnected world.

Benefits and Challenges of Implementation

The China Plus One strategy offers several benefits for companies looking to diversify their manufacturing bases. By establishing operations in additional countries, businesses can mitigate risks associated with political instability, trade tensions, or supply chain disruptions in China. This approach also enables companies to tap into new markets, access local resources, and leverage competitive advantage in regions with favorable labor costs or policies. Furthermore, having multiple production sites enhances flexibility, allowing firms to quickly respond to changing consumer demands and market conditions.

However, implementing the China Plus One strategy is not without its challenges. Businesses must navigate the complexities of establishing operations in new countries, including understanding local regulations, cultural differences, and labor market dynamics. Identifying suitable locations that align with operational needs and cost expectations can be daunting. Additionally, the transition may involve substantial investments in infrastructure and technology, which could strain financial resources and impact short-term profitability.

Moreover, companies may face supply chain complexities when juggling multiple production sites. Coordinating logistics, ensuring quality control, and maintaining effective communication across different locations can pose significant hurdles. Firms must also consider the potential risks associated with diversifying their supply chains, such as the reliability of local suppliers and the geopolitical landscape in the new regions. Balancing the benefits of diversification with these challenges requires careful planning and strategic decision-making.

Case Studies of Successful Adaptation

Many companies have successfully implemented the China Plus One strategy, enabling them to diversify their production and supply chains. For instance, a multinational electronics firm expanded its operations into Vietnam while maintaining its manufacturing base in China. This move not only mitigated risks associated with tariffs and political tensions but also allowed the company to leverage lower labor costs and a favorable business environment in Vietnam. As a result, the firm improved its flexibility in production and better managed supply chain disruptions.

Another example is a prominent apparel brand that shifted a portion of its manufacturing from China to Bangladesh. By doing so, the company capitalized on Bangladesh's reputation for affordable garment production. The decision was driven by the need for cost efficiency and responsiveness to changing consumer demands. This strategic shift successfully balanced the need for quality and speed in delivery, enabling the brand to remain competitive in the fast-paced fashion market.

Lastly, a major automobile manufacturer adopted the China Plus One strategy by establishing new production facilities in India. This allowed the company to tap into India's growing automotive market while also spreading its operational risks. The investment in India not only facilitated access to a young workforce but also positioned the manufacturer to benefit from local sourcing of materials and components. This diversification has enhanced the company's resilience and capacity for innovation in the crowded automotive industry.