Basics of Card Printing 2024

https://t.me/fakeidpro- How Card Printers Work

- Printing Process

- Magnetic Stripe Encoding

- Smart Card Encoding

- Card Lamination

- Card Security Features

- Glossary of Terms

Telegram channel: https://t.me/fakeidpro

How ID card printers work

The Original Way to Make ID Cards

Prior to the early 1990s, the most common method of producing an ID card was known as the film-based method. This involved taking a person’s photo, cutting it out and laminating it to a card-sized piece of paper containing the person’s name, ID number and any other personal information.

Although the initial investment for a film-based system was relatively low, the time, labor and individual cost per card was high. Plus, these cards were easily counterfeited. As a result, a new method called digital printing arose during the late 1980s and early 1990s.

Benefits of Digital Printing

Image quality

The image quality of plastic cards produced with digital printing technology is far superior to those produced through the traditional manual method described above. The cards look better because digitized photo images are sharper and can be edited for color quality. Placement of various graphical elements of the card is more consistent and text is clearer and more readable.

Flexibility

Plastic card printers can print text, line art and photographic images. They also can encode magnetic stripes and provide smart card chip programming contact stations, all in a single-step process. Card design software used to produce the cards provides users the flexibility to change designs, store and access multiple designs, create variable text fields and implement database programs to store images and track information.

Security

Plastic card printers also can apply various types of card protection materials to make cards resistant to tampering and alteration. These protection materials, including hologram overlays, make cards more secure because they cannot be easily reproduced or counterfeited.

Durability

Card protection materials such as overlay varnishes, overlaminate patches and secure card media each provide various levels of card durability by making the cards resistant to abrasion, UV light exposure, water damage and exposure to liquid chemicals.

Economy

In-house printing of plastic cards using a digital card printer takes far less time than the old film-based method. While the intial capital cost is higher, the cost per card is far less than the old method.

Convenience

Printing your own plastic cards gives you the convenience of being able to produce cards when you need them, where you need them, letting you issue new cards on demand. Having your own card printer capability also makes it easy to make changes to card content or design quickly.

Printing Process

Dye Sublimation and Thermal Transfer

Most plastic card printers feature the same basic printing operations - dye sublimation and/or thermal transfer printing. Both techniques involve a ribbon being heated as it passes under a thermal print head. The difference is that thermal transfer ribbons heat up and transfer ink onto the plastic card, and dye sublimation ribbons heat up and undergo a chemical change process that turns the ink into a gaseous state which then permeates the plastic card.

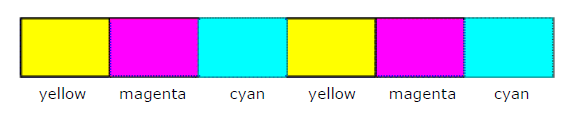

The ribbon used in color dye sublimation printing is divided into three separate color panels: yellow, magenta and cyan (see Figure 1). This configuration is referred to as YMC.

The ribbon used in color dye sublimation printing is divided into three separate color panels: yellow, magenta and cyan (see Figure 1). This configuration is referred to as YMC.

These three colors are the primary colors used in printing to produce all other colors including black.

The dye from the ribbon is applied to the plastic card via a multi-pass operation. This means the card will pass under the print head once for each of the three colored ribbon panels, applying each color separately.

The term dye sublimation also is referred to as dye diffusion. When the dye on the ribbon is heated by the print head it is transformed from a solid to a gas and diffused onto the plastic card (the card is specially coated to absorb the color dye). The hotter the elements in the print head, the more dye is converted to a gas and absorbed into the plastic card. At 300 dpi the picture quality and continuous color tones produced by a dye sublimation printer outperform most laser or ink jet printers with higher resolutions.

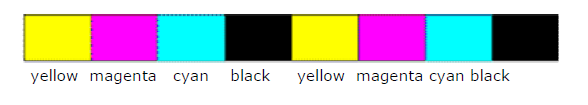

The advantage of dye sublimation is the millions of colors that can be created. The colors result from a combination of the panels on the ribbon. By combining these colors and varying the intensity of the heat, providing various shades of each color, you are virtually unlimited in your color selection. Thermal transfer differs from dye sublimation in that thermal transfer uses ink rather than dye. Both dye sublimation and thermal ink (sometimes refered to as resin) can be combined in one ribbon (see Figure 2). This ribbon is referred to as a YMCK ribbon. The letter "K" is the designator for the color black in the printing industry.

Why do you need a separate black panel, when you can create black by mixing the three basic YMC colors together?

The answer to this question is simple. When black is created by mixing the YMC colors together it creates what is referred to as "composite black." Composite black typically looks muddy or has a grayish tint when compared to thermal transfer (TT or resin) black. Composite black is not recommended for printing bar codes since combining the three colors together does not produce the sharp edge many scanners require (this is invisible to the naked eye but can be observed under magnification). Composite black also is invisible to IR scanners because there is no carbon in the dye. Since you may not know what type of scanner will be used, the rule is to always use TT (resin) black to print bar codes.

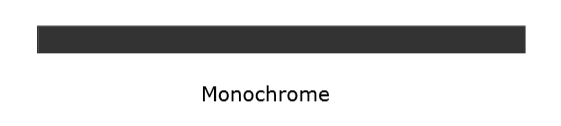

All color printers are capable of printing in monochrome using a single color ribbon. These ribbons are less expensive than full-color multi-panel ribbons and can be either dye or ink (thermal transfer). The most commonly used monochrome ribbon is black, but there are several other colors available, including red, green and blue.

Dye sublimation ribbons are preferred when you are printing pictures, because they can produce many shades of gray for a smoother look and a better picture quality. A resin black picture normally uses a dithered gray scale (gray made from a combination of pixels which limits the number of shades), producing a coarser, grainy look to the image.

Thermal transfer (resin) ribbons should be used to print text, bar codes or single color graphics such as simple logos. Black monochrome ribbons are represented by the letter "K" followed by a lower case "r or d", (Kr or Kd). The "r" designates a thermal transfer ribbon with resin ink. The "d" designates a dye sublimation ribbon.

Reverse transfer

This process prints images on the reverse side of a retransfer film. The film is then laminated to the face of a PVC card with heat and pressure. The process uses the same four color panels as a dye sublimation printer but produces much higher quality because the dye bleeds less on the film than it does on a PVC card. Also, since the film is laminated to the card it is virtually impossible to tamper with the card without destroying it.

Inkjet printing

Inkjet printing has been around for a long time and is common in today's office. However, it has just been introduced to ID card printing. Currently, only Fargo has inkjet printers and they require specially formulated ink and PVC cards to work.

There are three main steps to producing a drop with thermal technology. First, the chamber holding the ink bubble is heated. Second, the bubble bursts due to heat and the ink drop shoots out of the nozzle. Finally, the vacuum from the drop leaving the chamber draws the next bubble into the chamber. There are between 300 and 600 nozzles per print head, all of which can fire at the same time. "These deliver drop volumes of around 8 - 10 [picoliters] (a [picoliter] is a million millionth of a [liter]), and dot sizes of between 50 and 60 microns in diameter." Thirty microns is the smallest dot size visible to the naked eye.

There are 300 to 600 of these firing mechanisms per print head. Four to eight of these tiny drops are fired onto the paper to make a color dot. Larger dots of 35 picoliters are usually created with black inks. Part of this difference is that the colors are usually created with dye-based ink and the black ink is a pigment-based ink. Dye-based inks produce a wide range of vibrant colors whereas pigment-based inks are more durable and water-resistant. Pigment-based inks also have larger molecules because they are particles suspended in solution. Because thermal technology uses heat to create the drop, all the inks used must be heat resistant. This narrows the selection of inks and their characteristics such as water-resistance.

Magnetic Stripe Encoding

Magnetic stripe cards have been in existence since the early 1970s when they were used on paper and filmbased ID cards as well as credit cards. Magnetic stripe technology is widely used throughout the world and remains the dominant technology in the United States for transaction processing and access control. Other technologies such as PDF bar codes and smart chip cards now are capturing part of the magnetic stripe market because they can hold more information.

Magnetic stripe encoding terms:

Coercivity

A technical term used to designate how strong a magnetic field must be to affect data encoded on a magnetic stripe. Coercivity is measured in Oersteds (Oe). Coercivity is the measure of how difficult it is to encode information in a magnetic stripe.

HiCo

Abbreviation for High Coercivity. HiCo magnetic stripes provide the highest level of immunity to damage by stray magnetic fields. They are more difficult to encode than LoCo magnetic stripes because the encoding requires more power. HiCo magnetic stripe cards are slightly more expensive for this reason.

LoCo

Abbreviation for Low Coercivity. Easier to encode and slightly less expensive than HiCo magnetic stripe cards.

ISO Magnetic Stripe Encoding

International Standards Organization specification for magnetic stripe encoding. The Fargo encoder supports dual high/low coercivity and tracks 1, 2 and 3.

JIS II Magnetic Stripe Encoding

Japanese Industrial Standard for magnetic stripe encoding; published and translated into English by Japan Standards Association.

Stripe-up/Stripe-down

Stripe-up means the magnetic stripe is on the front of the card and stripe-down means the magnetic stripe is on the back of the card. This information is important when ordering a printer since the magnetic encoder must be installed differently for stripe-up and stripe-down models at the factory. The most common is stripe-down.

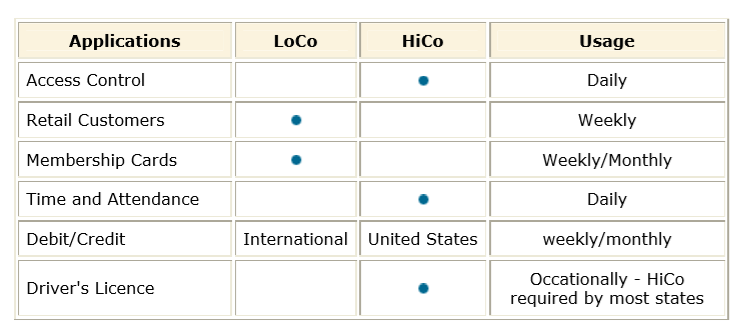

Select the right type for the job

Selecting which type of magnetic stripe to adopt depends on how the card is to be used. Will the magnetic stripe be used daily, once a month or just a couple of times a year? The chart below shows some of the applications where magnetic stripes are used and which stripe is common for that application.

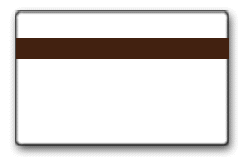

How to visually identify which kind of stripe is on a card

The easiest way to determine visually if a stripe on a card is HiCo or LoCo is by the color. HiCo stripes are black and LoCo stripes are a lighter brown. Magnetic stripe readers are "blind" as to whether a stripe is HiCo or LoCo and are designed to read both.

Smart Card Encoding

There are a wide variety of contact and contactless smart cards currently in use. The terms "smart chip card," "IC card" and "smart card" all refer to the same type of card. Smart cards have a chip embedded in them which can be programmed. Smart cards can store more than 100 times more information than a magnetic stripe and they can be reprogrammed to add, delete or rearrange data.

Smart cards were invented in Europe in the 1970s and were in wide use in Western Europe by the early '80s. Smart cards are an easy, inexpensive way for European businesses to do offline transaction verification. The reason offline verification is preferred is the high cost of telecommunications throughout Europe. The United States has been slow to implement smart cards because it would require replacing the widely installed magnetic stripe card reading equipment with smart card readers. The cost of having the current magnetic stripe readers "online" via telecommunications is relatively inexpensive in the U.S. compared to the rest of the world.

The second type of smart card contains both a microprocessor as well as memory. These cards can store massive amounts of information, plus the microprocessor enables the card to make its own decisions regarding the information stored.

Both types of chips can be addressed by Eltron card printers since they all offer an optional smart card contact station. The printer brings the card into the contact station and then passes programming signals from an external programmer to encode the smart chip.

Contactless smart cards utilize various RFID technologies to write and read. Many card printers print on these kinds of smart cards. Encoding or programming the electronic devices on these cards is typically accomplished by an external encoding or programming device, but contactless smart card encoders integrated into the card printer are becoming increasingly available.

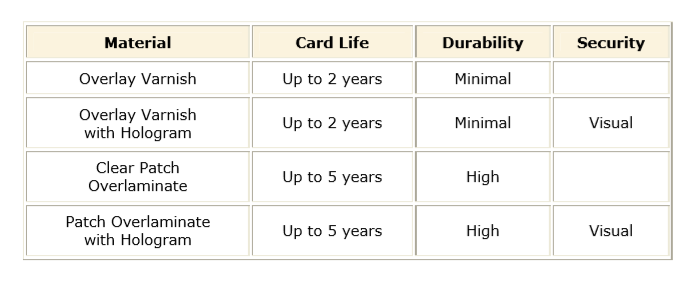

Card Lamination

Various types of materials are used to protect plastic cards from abrasion, wear, fading, alteration and duplications. Overlay varnishes and laminate patches are the most common materials used to enhance card durability and security.

Card durability has to do with how well the card withstands various forms of environmental stress. They include resistance to abrasion, such as passing the card through a magnetic stripe or bar code reader, protection from image fading when exposed to sunlight, and resistance to damage when immersed in water or exposed to chemicals.

Another important factor in applications such as driver's licensing is resistance to tampering, alteration and/or replication. With the use of protective materials such as laminate patches with holograms, cards can be constructed to eliminate the potential of tampering and alteration.

Card security means that the card can be verified for authenticity. Techniques include the application of overlay varnish or overlaminate materials with hologram images. Use of these materials in constructing cards makes replication by anyone without access to the custom hologram image materials virtually impossible.

Overlay varnishes provide card protection, but have a much shorter life span that laminate patches - and offer very little security (with the exception of some hologram varnishes). Varnishes are not a solid covering and have multiple tiny holes in the surface, which allows the dyes to be drawn away from the card. This will cause the image on the card to blur and fade due to UV light, shift in color or just wear away. The life expectancy of a plain plastic card is up to two years.

Laminate patches offer better protection than plain varnish, for both security and life expectancy. A patch laminate is, as its name implies, a polyester patch that is applied to the surface of the card after printing. Laminate patches, most often either .6 or 1.0 mil thick are applied via a hot roll laminating station. The life expectancy of a plastic card with a laminate patch is up to seven years.

Glossary of Terms

Access Control Cards

Plastic cards used to gain access to premises, usually associated with magnetic stripe and proximity cards.

Bar Code

An array of machine-readable rectangular bars and spaces arranged in a specific way defined in international standards to represent letters, numbers and other human-readable symbols.

Biometrics

Biometrics utilize "something you are" to authenticate identification. This might include fingerprints, retina pattern, iris, hand geometry, vein patterns, voice password or signature dynamics. Biometrics can be used with a smart card to authenticate the user. The user's biometric information is stored on a smart card, the card is placed in a reader and a biometric scanner reads the information to match it against that on the card. This is a fast, accurate and highly secure form of user authentication.

Coercivity

A technical term used to designate how strong a magnetic field must be to affect data encoded on a magnetic stripe. Coercivity is measured in Oersteds (Oe). Coercivity is the measure of how difficult it is to encode information in a magnetic stripe.

Color Matching

Several color matching options are included with Fargo Card Printer/Encoders. These options are built directly into the printer driver so they are easily selected. Colors print with more clarity, detail and accuracy.

Contact Smart Card Encoder

The contact smart card encoder connects the ISO contact pins mounted on the e-card docking station to a Gemplus GemCore 410 smart card coupler mounted inside the printer. The GemCore 410's digital I/O is converted to a RS-232 signal which is accessible to application programs through a dedicated DB-9 port on the outside of the printer labeled "Smart Card."

Contactless Smart Card Encoder

The contactless smart card encoder connects an antenna mounted on the e-card docking station to a Gemplus GemEasyLink 680SL coupler mounted inside the printer/encoder. Application programs can access Mifare® contactless cards via a RS-232 signal through a dedicated DB-9 port on the outside of the printer labeled "Mifare/Contactless."

Digital Imaging

Scanning or otherwise capturing images which may be subsequently edited, filed, displayed or printed on a plastic card.

Direct-to-Card (DTC) Printing

The Direct-to-card printing process prints digital images directly onto any plastic card with a smooth, clean, glossy PVC surface.

Dye Sublimation

Dye sublimation is the print process Fargo Card Printer/Encoders use to print smooth, continuous-tone, photo-quality images. This process uses a dye-based ribbon roll that is divided into a series of color panels. The color panels are grouped in a repeating series of three separate colors along the length of the ribbon: yellow, magenta and cyan (YMC). As the ribbon and card pass simultaneously beneath the printhead, hundreds of thermal elements heat the dyes on the ribbon. Once the dyes are heated, they vaporize and diffuse into the surface of the card. Varying the heat intensity of each thermal element within the printhead makes it possible for each transferred dot of color to vary saturation. This blends one color into the next. The result is continuous-tone, photo-realistic color images.

Docking Station

Fargo provides an optional e-card docking station on select models that can be ordered with encoders for one, two or three different types of e-cards. These printer/encoders allow application software to read and/or store information in the memory of e-cards. The optional encoders provide everything needed for an application program to communicate with a specific type e-card through a standard RS-232 interface. The Fargo e-card docking station comes standard with the read/write pins (as defined by ISO) needed to communicate with contact smart cards. The e-card docking station also can be ordered with a magnetic stripe encoder for either an ISO magnetic stripe that supports dual high/low coercivity tracks 1, 2 and 3 or a JIS II magnetic stripe.

Encoding

The process of electronically "writing" information on magnetic stripes or smart card chips.

E-card Encoder

Fargo Card Printer/Encoders support reading and/or storing information in up to three different types of ecards: ISO 7816 contact smart cards, Mifare® contactless smart cards and HID proximity cards.

Edge-to-Edge

Refers to the maximum printable area on a card. Printer/encoders with edge-to-edge printing capability can print just to the edge of a card resulting in printed cards with virtually no border.

HiCo

Abbreviation for High Coercivity. HiCo magnetic stripes provide the highest level of immunity to damage by stray magnetic fields. They are more difficult to encode than LoCo magnetic stripes because the encoding requires more power. HiCo magnetic stripe cards are slightly more expensive for this reason.

High-Volume Printing

Fast, efficient printing for producing large quantities of cards with minimal down time for supplies loading or maintenance.

High Definition Printing™ (HDP™)

The high-definition printing process prints full-color images onto clear HDP transfer film. The HDP film is then fused to the card through heat and pressure via a heated roller. This revolutionary technology enhances card durability and consistently produces the best card color available - even on tough-to-print matte-finished cards, proximity cards and smart cards.

High-Speed Printing

Fargo Card Printer/Encoders are among the fastest desktop card printer/encoders in the industry. Highspeed printing allows for more efficient card production - saving time, money and resources.

Hologram

A unique photographic printing that provides a three-dimensional effect on a flat surface. Holograms cannot be easily copied and are used for security and aesthetic purposes on cards.

Image Capture System

A hardware and software system used to obtain and save personal data and cardholder photographic images.

ISO Magnetic Stripe Encoder

International Standards Organization specification for magnetic stripe encoding. The Fargo encoder supports dual high/low coercivity and tracks 1, 2 and 3.

JIS II Magnetic Stripe Encoder

Japanese Industrial Standard for magnetic stripe encoding; published and translated into English by Japan Standards Association.

Lamination

The process of combining lamination material and core material using time, heat and pressure. Laminate patches used in card printers come on rolls, with and without carriers/liners.

LCD Display

The LCD - or Liquid Crystal Display - shows the current status of the printer and changes according to the printer's current mode of operation. LCD communicates an error with text, which is easier to interpret than LED lights.

Lockable Hopper

Some Fargo Card Printer/Encoders provide a lockable card hopper door. This lock is intended to help prevent theft of your blank card stock. This feature is especially helpful if using valuable card stock such as preprinted cards, smart cards or cards with built-in security features such as holograms.

LoCo

Abbreviation for Low Coercivity. Easier to encode and slightly less expensive than HiCo magnetic stripe cards.

Machine-Readable

A code or characters that can be read by machines.

Magnetic (“Mag”) Stripe

Mag stripe refers to the black or brown magnetic stripe on a card. The stripe is made of magnetic particles of resin. The resin particle material determines the coercivity of the stripe; the higher the coercivity, the harder it is to encode - and erase - information from the stripe. Magnetic stripes are often used in applications for access control, time and attendance, lunch programs, library cards and more.

Memory Card

A type of smart card. Also known as a synchronous card, it features 256 bit or 32 byte memory and is suitable for use as a token card or identification card.

Output Stacker

The output stacker stores printed cards in a first-in/first-out order. This feature makes it easy to keep printed cards in a specific order for faster issuance or to print serialized cards.

Oversized Cards

Oversized cards are used for more efficient visual identification and are available in many nonstandard sizes. The most popular sizes are CR-90 (3.63" x 2.37"/92 mm x 60 mm) and CR-100 (3.88" x 2.63"/98.5 mm x 67 mm).

Overlaminate

Protective clear or holographic material designed to offer advanced card security and durability. Two types are available from Fargo: Thermal Transfer Overlaminate is a .25 mil thick material that enhances card security and durability. PolyGuard Overlaminate is available in a 1 mil and .6 mil thick material and provides extraordinary protection for applications that require highly durable cards.

Overlay Panel

The clear overlay panel (O) is provided on dye sublimation print ribbons. This panel is automatically applied to printed cards and helps prevent images from premature wear or UV fading. All dye sublimation printed images must have either this overlay panel or an overlaminate applied to protect them.

Overlay Varnish

A thin transparent layer applied (using the print head) to cards to resist scratching and fading from exposure to UV radiation.

Over-the-Edge

Refers to the maximum printable area on a card. Printer/encoders with over-the-edge printing capability can print past the edge of a card resulting in printed cards with absolutely no border.

PolyGuard™

A card overlaminate available in 1 mil and .6 mil thicknesses that provides extraordinary card protection; ideal for harsh or more secure environments. Available as clear or with embedded holographic-type security images.

Proximity (“Prox”) Card

Proximity cards allow access and tracking utilizing contactless technology (usually by communicating through a built-in antenna).

Prox Card Encoder

The prox card encoder uses a HID ProxPoint® Plus reader mounted on the e-card docking station inside the printer/encoder. The ProxPoint is a "read only" device producing a Wiegand signal that is converted to RS232 using a Cypress Computer Systems CVT-2232. Application programs can read information from HID prox cards via a RS-232 signal through a dedicated DB-9 port on the outside of the printer labeled "Prox."

Resin Thermal Transfer

Resin thermal transfer is the process used to print sharp black text and crisp bar codes that can be read by both infrared and visible-light bar code scanners. It is also the process used to print ultra-fast, economical one-color cards. Like dye sublimation, this process uses a thermal printhead to transfer color from the ribbon roll to the card. The difference, however, is that solid dots of color are transferred in the form of a resin-based ink which fuses to the surface of the card when heated. This produces very durable, single-color images.

Smart Card

Smart cards have an embedded computer circuit that contains either a memory chip or a microprocessor chip. There are several types of smart cards: Memory, Contact, Contactless, Hybrid (Twin), Combi (Dual Interface), Proximity and Vicinity.

SmartGuard™

SmartGuard is a printer security option that uses a custom access card and a built-in reader to restrict printer access. With this feature, only those with a valid access card can print cards. This makes both your printed cards and your overall system more secure.

SmartShield™

This option allows the printer/encoder to print custom, reflective security images on the card that fluoresce under a black or UV light source.

Standard Cards

The standard card size is CR-80. CR-80 dimensions are 3.375" x 2.125" (85.6 mm x 54 mm).

Thermal Printing

The process of creating an image on a plastic card using a heated printhead.

Thermal Transfer Overlaminate

A card overlaminate available in a .25 mil thickness that increases card security and durability; often used for moderate durability applications or when additional security (such as holographic images) are needed.

Resolution

Dimension of the smallest element of an image that can be printed. Usually stated as dots per inch (dpi).

YMC

Yellow, magenta and cyan are the primary print colors for cards. The three colors are combined in varying degrees to make a full spectrum of colors. YMCKO is the same as YMC plus black (K) and clear protective overcoat (O).