Awg Outdoor

🛑 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

Awg Outdoor

From Wikipedia, the free encyclopedia

"AWG" redirects here. For other uses, see AWG (disambiguation) .

^ or, equivalently, Ω /km

^ or, equivalently, Ω/kft

^ Jump up to: a b c d Exactly, by definition

^ "ASTM B258-14 Standard Specification for Standard Nominal Diameters and Cross-sectional Areas of AWG Sizes of Solid Round Wires Used as Electrical Conductors" . West Conshohocken : ASTM International . Archived from the original on 22 July 2014 . Retrieved 22 March 2015 .

^ SteelNavel.com Body Piercing Jewelry Size Reference — illustrating the different ways that size is measured on different kinds of jewelry

^ The logarithm to the base 92 can be computed using any other logarithm, such as common or natural logarithm , using log 92 x = (log x )/(log 92).

^ ASTM Standard B258-02, page 4

^ The result is roughly 2.0050, or one-quarter of one percent higher than 2

^ Copper Wire Tables (Technical report). Circular of the Bureau of Standards No. 31 (3rd ed.). United States Department of Commerce. October 1, 1914.

^

Figure for solid copper wire at 68 °F , (Not in accordance to NEC Codebook 2014 Ch. 9, Table 8) computed based on 100% IACS conductivity of 58.0 M S /m, which agrees with multiple sources:

Lund, Mark. "American Wire Gauge table and AWG Electrical Current Load Limits" . Powerstream.com . Retrieved 2008-05-02 . (although the ft/m conversion seems slightly erroneous)

Belden Master Catalog, 2006, although data from there for gauges 35 and 37–40 seems obviously wrong.

High-purity oxygen-free copper can achieve up to 101.5% IACS conductivity; e.g., the Kanthal conductive alloys data sheet lists slightly lower resistances than this table.

^

NFPA 70 National Electrical Code 2014 Edition Archived 2008-10-15 at the Wayback Machine . Table 310.15(B)(16) (formerly Table 310.16) page 70-161, "Allowable ampacities of insulated conductors rated 0 through 2000 volts, 60°C through 90°C, not more than three current-carrying conductors in raceway, cable, or earth (directly buried) based on ambient temperature of 30°C." Extracts from NFPA 70 do not represent the full position of NFPA and the original complete Code must be consulted. In particular, the maximum permissible overcurrent protection devices may set a lower limit.

^ "Table 11: Recommended Current Ratings (Continuous Duty) for electronic equipment and chassis wiring". Reference Data for Engineers: Radio, Electronics, Computer and Communications (7th ed.). pp. 49–16.

^

Computed using equations from Beaty, H. Wayne; Fink, Donald G., eds. (2007), The Standard Handbook for Electrical Engineers (15th ed.), McGraw Hill, pp. 4–25, ISBN 978-0-07-144146-9

^

Brooks, Douglas G. (December 1998), "Fusing Current: When Traces Melt Without a Trace" (PDF) , Printed Circuit Design , 15 (12): 53

^

Preece, W. H. (1883), "On the Heating Effects of Electric Currents" , Proceedings of the Royal Society (36): 464–471

^

Preece, W. H. (1887), "On the Heating Effects of Electric Currents" , Proceedings of the Royal Society , II (43): 280–295

^

Preece, W. H. (1888), "On the Heating Effects of Electric Currents" , Proceedings of the Royal Society , III (44): 109–111

^ Jump up to: a b

Brooks, Douglas G.; Adam, Johannes (29 June 2015), "Who Were Preece and Onderdonk?" , Printed Circuit Design and Fab

^

Stauffacher, E. R. (June 1928), "Short-time Current Carrying Capacity of Copper Wire" (PDF) , General Electric Review , 31 (6)

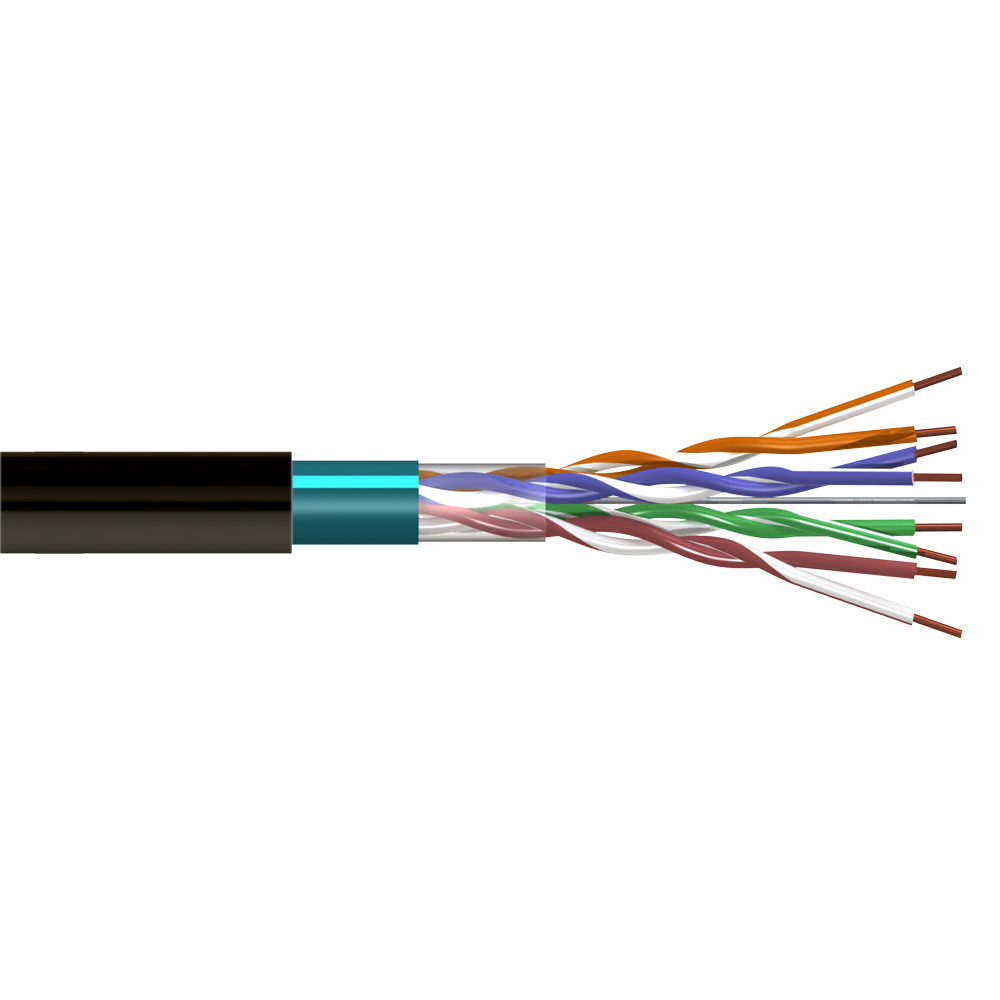

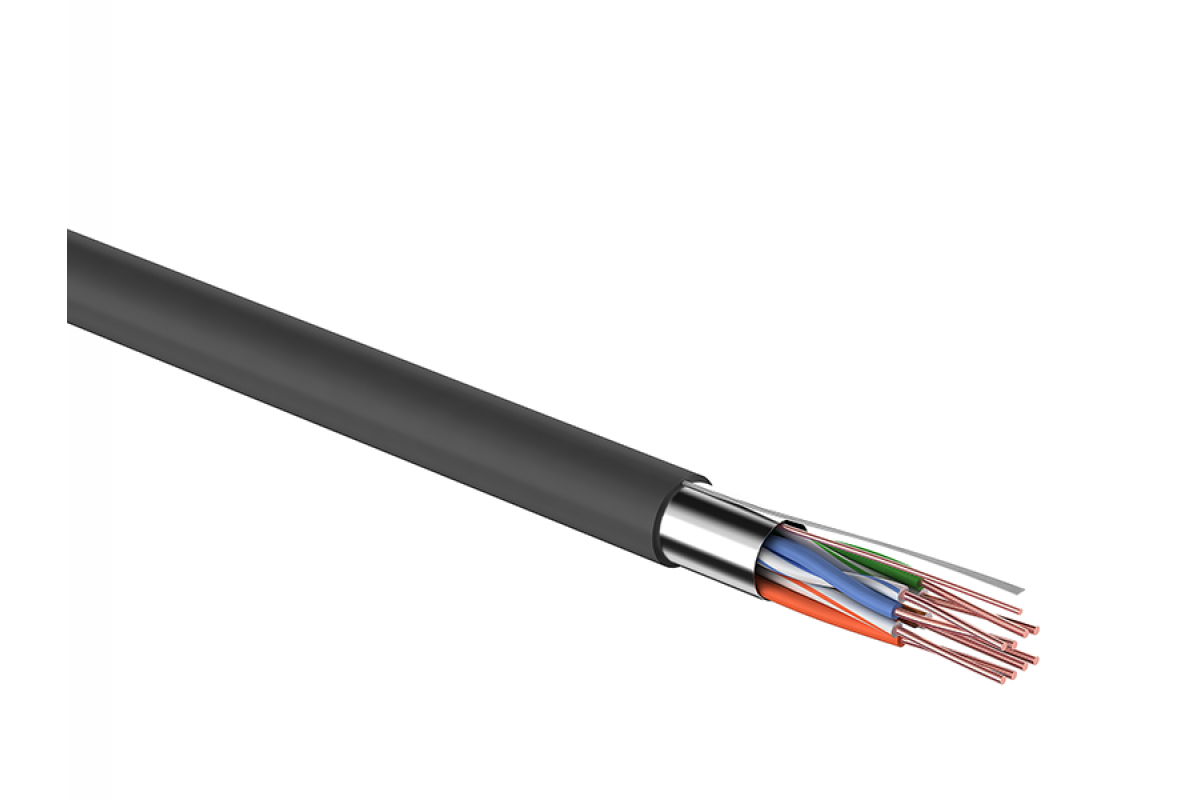

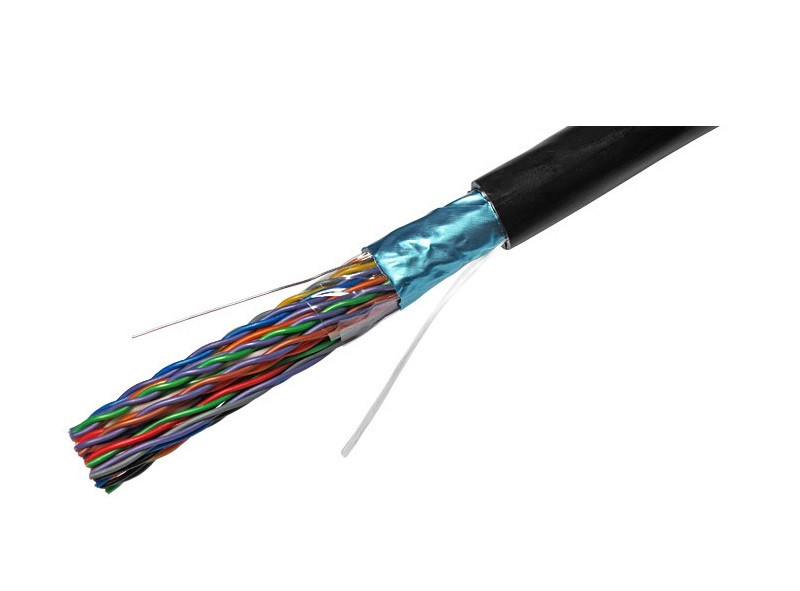

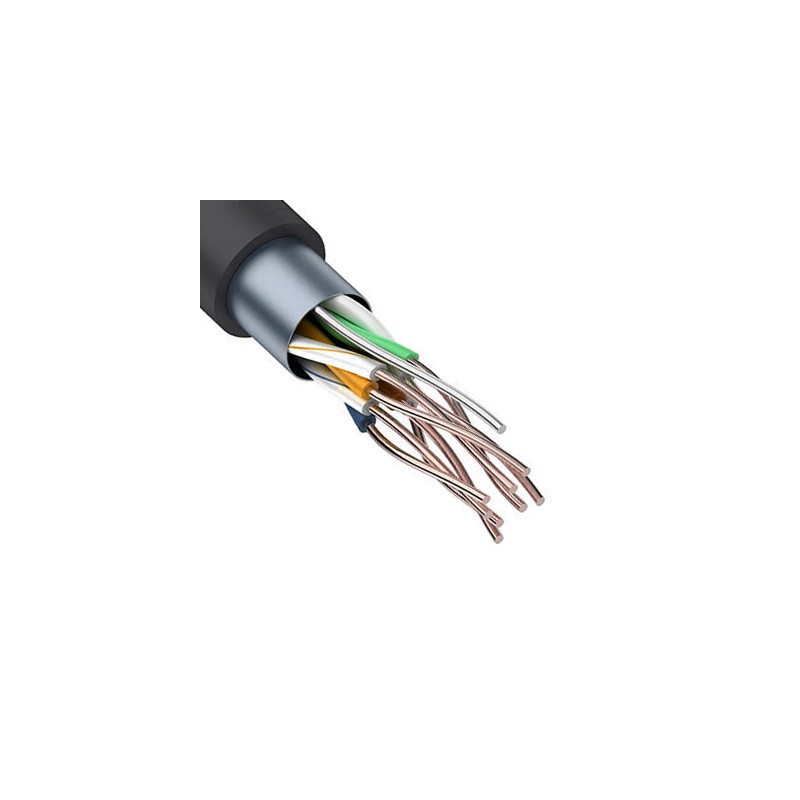

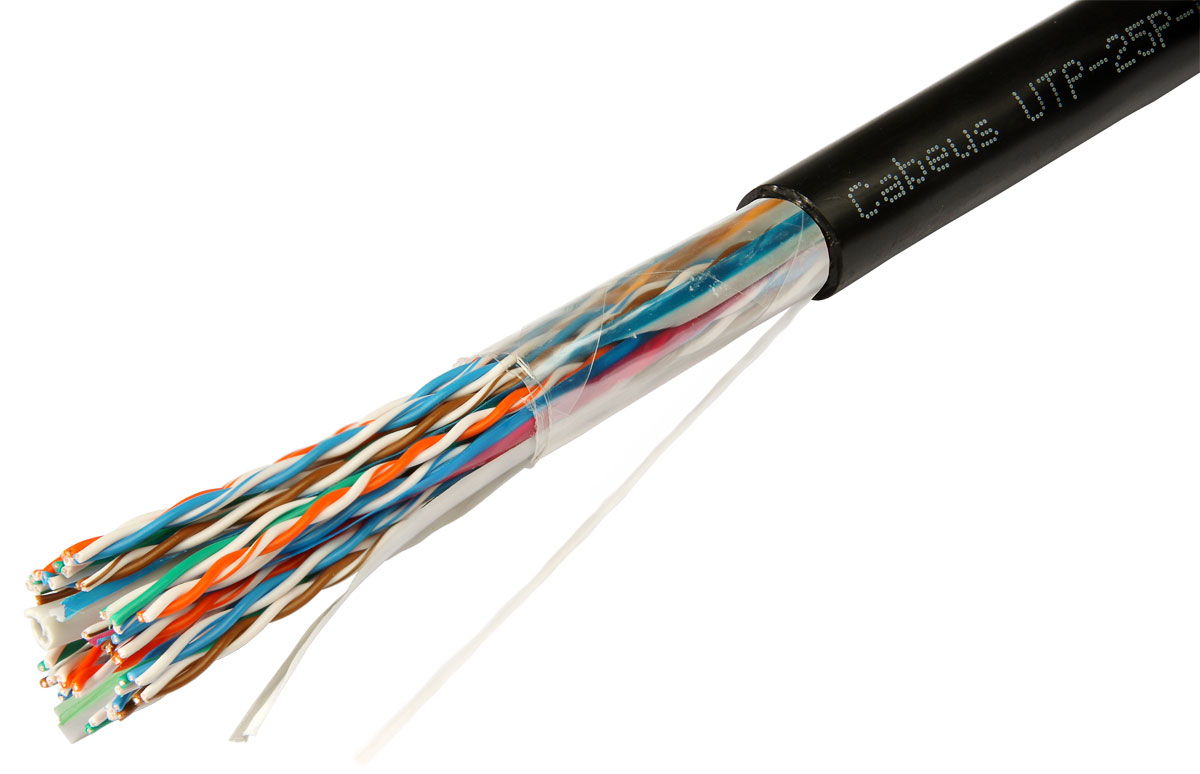

American Wire Gauge ( AWG ), also known as the Brown & Sharpe wire gauge , is a logarithmic stepped standardized wire gauge system used since 1857, predominantly in North America , for the diameters of round, solid, nonferrous, electrically conducting wire. Dimensions of the wires are given in ASTM standard B 258. [1] The cross-sectional area of each gauge is an important factor for determining its current-carrying ampacity .

Increasing gauge numbers denote decreasing wire diameters, which is similar to many other non-metric gauging systems such as British Standard Wire Gauge (SWG), but unlike IEC 60228 , the metric wire-size standard used in most parts of the world. This gauge system originated in the number of drawing operations used to produce a given gauge of wire. Very fine wire (for example, 30 gauge) required more passes through the drawing dies than 0 gauge wire did. Manufacturers of wire formerly had proprietary wire gauge systems; the development of standardized wire gauges rationalized selection of wire for a particular purpose.

The AWG tables are for a single, solid and round conductor. The AWG of a stranded wire is determined by the cross-sectional area of the equivalent solid conductor. Because there are also small gaps between the strands, a stranded wire will always have a slightly larger overall diameter than a solid wire with the same AWG.

AWG is also commonly used to specify body piercing jewelry sizes (especially smaller sizes), even when the material is not metallic. [2]

By definition, No. 36 AWG is 0.005 inches in diameter, and No. 0000 is 0.46 inches in diameter. The ratio of these diameters is 1:92, and there are 40 gauge sizes from No. 36 to No. 0000, or 39 steps. Because each successive gauge number increases cross sectional area by a constant multiple, diameters vary geometrically. Any two successive gauges (e.g., A and B ) have diameters whose ratio (dia. B ÷ dia. A ) is

92

39

{\displaystyle {\sqrt[{39}]{92}}}

(approximately 1.12293), while for gauges two steps apart (e.g., A , B , and C ), the ratio of the C to A is about 1.12293 2 = 1.26098. The diameter of a No. a AWG wire is determined, for gauges smaller than 00 (36 to 0), according to the following formula:

(See below for gauges larger than No. 0, i.e., No. 00, No. 000, No. 0000.)

The gauge can be calculated from the diameter using [3]

The standard ASTM B258-02 (2008), Standard Specification for Standard Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as Electrical Conductors , defines the ratio between successive sizes to be the 39th root of 92, or approximately 1.1229322. [4] ASTM B258-02 also dictates that wire diameters should be tabulated with no more than 4 significant figures, with a resolution of no more than 0.0001 inches (0.1 mils) for wires larger than No. 44 AWG, and 0.00001 inches (0.01 mils) for wires No. 45 AWG and smaller.

Sizes with multiple zeros are successively larger than No. 0 and can be denoted using " number of zeros /0", for example 4/0 for 0000. For an m /0 AWG wire, use n = −( m − 1) = 1 − m in the above formulas. For instance, for No. 0000 or 4/0, use n = −3 .

The sixth power of 39 √ 92 is very close to 2, [5] which leads to the following rules of thumb:

The table below shows various data including both the resistance of the various wire gauges and the allowable current ( ampacity ) based on a copper conductor with plastic insulation. The diameter information in the table applies to solid wires. Stranded wires are calculated by calculating the equivalent cross sectional copper area . Fusing current (melting wire) is estimated based on 25 °C (77 °F) ambient temperature. The table below assumes DC , or AC frequencies equal to or less than 60 Hz, and does not take skin effect into account. "Turns of wire per unit length" is the reciprocal of the conductor diameter; it is therefore an upper limit for wire wound in the form of a helix (see solenoid ), based on uninsulated wire.

In the North American electrical industry, conductors larger than 4/0 AWG are generally identified by the area in thousands of circular mils (kcmil), where 1 kcmil = 0.5067 mm 2 . The next wire size larger than 4/0 has a cross section of 250 kcmil. A circular mil is the area of a wire one mil in diameter. One million circular mils is the area of a circle with 1000 mil (1 inch) diameter. An older abbreviation for one thousand circular mils is MCM .

AWG gauges are also used to describe stranded wire. The AWG gauge of a stranded wire represents the sum of the cross-sectional areas of the individual strands; the gaps between strands are not counted. When made with circular strands, these gaps occupy about 25% of the wire area , thus requiring the overall bundle diameter to be about 13% larger than a solid wire of equal gauge.

Stranded wires are specified with three numbers, the overall AWG size, the number of strands, and the AWG size of a strand. The number of strands and the AWG of a strand are separated by a slash. For example, a 22 AWG 7/30 stranded wire is a 22 AWG wire made from seven strands of 30 AWG wire.

As indicated in the Formulas and Rules of Thumb sections above, differences in AWG translate directly into ratios of diameter or area. This property can be employed to easily find the AWG of a stranded bundle by measuring the diameter and count of its strands. (This only applies to bundles with circular strands of identical size.) To find the AWG of 7-strand wire with equal strands, subtract 8.4 from the AWG of a strand. Similarly, for 19-strand subtract 12.7, and for 37 subtract 15.6. See the Mathcad worksheet illustration of this straightforward application of the formula.

Measuring strand diameter is often easier and more accurate than attempting to measure bundle diameter and packing ratio. Such measurement can be done with a wire gauge go-no-go tool such as a Starrett 281 or Mitutoyo 950–202, or with a caliper or micrometer.

Alternative ways are commonly used in the electrical industry to specify wire sizes as AWG.

AWG is colloquially referred to as gauge and the zeros in large wire sizes are referred to as aught / ˈ ɔː t / . Wire sized 1 AWG is referred to as "one gauge" or "No. 1" wire; similarly, smaller diameters are pronounced " x gauge" or "No. x " wire, where x is the positive-integer AWG number. Consecutive AWG wire sizes larger than No. 1 wire are designated by the number of zeros:

Find great deals on eBay for outdoor cable awg . Shop with confidence.

American wire gauge - Wikipedia

5 PCS 2 5 Core Pin Black Plastics Waterproof IP65 T Shape... - AliExpress

Amazon.com: trueCABLE Cat5e Outdoor Shielded (FTP), 1000ft, Waterproof...

VIVO Black Full Copper 500 ft Cat6 Ethernet Cable 23 AWG / Wire ... - YouTube

Home

>

All Categories

>

Lights & Lighting

>

Lighting Accessories

>

Connectors

4.9

(16 votes)

Store:

BTF-LIGHTING Official Store

Related Search:

connector connect

connector set

electrical connector connection

connector neutrik

pin connectors

200w ip65 connector

lever wago

14 gauge copper wire

amp tyco

Hot Search:

long walk

jack moto

excellent

inventors

equipment

free bdsm

lol games

edelvives

iphone 12

categroy:

LED Chips

Portable Lighting Accessories

Lamp Tooth Tube

Lamp Radiators

Ballasts

Chandelier Crystal

Connectors

Dimmers

Flashlight Mount Holders

New user coupon on orders over US $4.00

Money Back Guarantee

Refund in 15 Days

5 PCS 2-5 Core Pin Black Plastics Waterproof IP65 T Shape Tee Connector 2 Male Ends 1 Female End 18AWG 20AWG 22AWG 24AWG Outdoor

2-5 Core Pin Waterproof Tee connector.1 Male connector 2 female connectors. Support 2-5 Core Pin straight waterproof connector and waterproof cable wire.

High quality material, making soldering easy.No loose, reliable and lightweight. Material: PVC + Copper wire,eliable and safe, no loose, lightweight and beautiful appearance.

Connect reliablely and effective IP65 waterproof.Wide range of uses, Motorcycles,Car,Truck,Boat,Indoor Outdoor Single Color LED Strip Lights LED String WS2811 WS2812B WS2815 SK6812RGBW SK9822 3 PIN 4 PIN LED addressable strip.

This male/female connector is a very useful accessory when installing waterproof LED lights.

2pin 0.3mm2=22AWG=2-3A, 2pin 0.75mm2=18AWG=5-6A.

3pin 0.3mm2=22AWG=3A, 3pin 0.75mm2=18AWG=5-6A.

4pin 0.2mm2=24AWG=2A, 4pin 0.5mm2=20AWG=4-5A.

5pin 0.2mm2=24AWG=2A, 5pin 0.3mm2=22AWG=3A.

Package: 5 PCS 2-5 Core Pin Black Waterproof IP65 T Shape Connector.

If you need special length, please contact us to customize.

Naked Ass Tranny Fucked Hard

Cassidy Klein Hotwife

Granny Women

Oral Sex Home Video

Family Nudists Video Hd