An Unbiased View of Plastic Extruded Profiles

John Wynn

At Vip, we have years of experience production hundreds of special personalized plastic extrusions in practically every shape, size, and also color you can think of. Our specialty lies in making plastic profiles particularly for a specific application. You inform us what you need as well as we will certainly make it, fulfilling the highest possible quality requirements.

From pre-prototype to post-production, ACE has the ability and also modern technology to do all of it. We serve large as well as little business in industries ranging from automotive to clinical, with challenging product requirements to limited resistances in America, Canada, Mexico, and also Europe (custom plastic extrusions). No matter of where you are or what industry you represent, you can rely on ACE for customized service as well as customer satisfaction.

That means quick quote service or material recommendation is simply a phone call away. Your questions are constantly addressed quickly by our proficient solution staff, as well as you obtain the aid you need with no hold-ups or confusion. Thanks for visiting our website, we are right here to assist you. Please contact your ACE sales agent at 414-332-8133 or email to review services and products.

Get This Report about Plastic Extruded Profiles

With over 100 combined years of experience in plastic extrusion, GSH Industries is a leading B2B vendor of custom-made plastic extrusions, tubing, as well as plastic profiles in North Ohio. Our designers and designers can help you in choosing the very best materials for your line of product. We have a large option of plastic materials and can match any kind of personalized colors to your customer's specs.

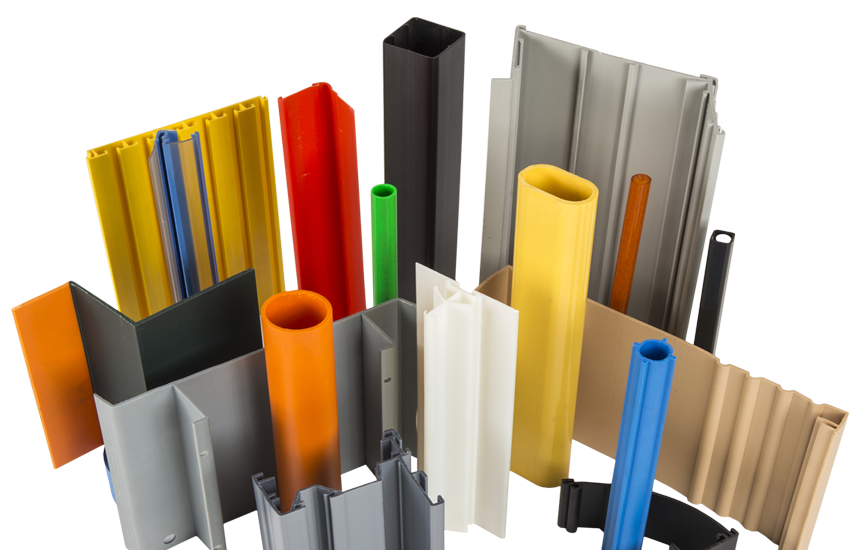

It is one of the most popular means plastic parts are presently created due to its convenience (plastic profile extrusion). Customized extrusions can be developed into intricate forms of varying thicknesses, staminas, sizes, shades, and also also structures, and also are relatively very easy to work with. The extrusions can likewise be created with efficiency enhancing qualities such as fire resistance, enhanced resilience, enhanced stamina, anti-friction or anti-static residential or commercial properties, and also far more.

It can also potentially result in longer cooling time with will enhance your general production time and prices. Sharp corners and also notches produce powerlessness in the profile where cracking or failing can occur given that they decrease the influence resistance of the account by producing a high stress focus. Ideally, when making your profile extrusion sharp corners ought to be prevented completely rather go for rounded edges.

Custom Plastic Profiles Can Be Fun For Everyone

015" (0. 381 mm). Preferably the radius needs to be equivalent to the wall surface thickness of the extrusion. This contributes to smoother product flow during extrusion as well as less tension on the account's corners. Hollow accounts as well as other information include quite a bit of intricacy to an extruded shape. They need added modifications to the die to make sure appropriate material flow, can create uneven air conditioning, as well as can trigger locations of weak point that can lead to failure.

If your part should have hollows, a hollow within one more hollow is never ever a great idea (extrusion of plastics). It will be required out of shape before the extrusion strengthens. If your extrusion requires attributes such as legs, grooves, snap-ins, or various other products within the extrusion it is best to create an easily available opening into the extrusion to make sure that you can much better include those features.

The measurements give the certain dimension of the component while the resistance reveals the allowable amount over or listed below the dimension while remaining within the specifications. Because thermoplastics contract and also broaden as their temperature levels transform it is an excellent concept to enable a little bit a lot more flexibility in the size of the extrusion - plastic extrusion companies.

Extrusion Of Plastics for Beginners

Knowing some consumers may be not familiar with our plastic account extrusion capabilities, we have actually assembled a list of concerns we are often asked - custom plastic extrusion manufacturers. Durometer is a dimension of the product's firmness and is gauged with a device which is pushed versus the profile's surface, leading to a dial guage reading.

Common ranges are Shore A for flexible materials and also Shore D for stiff compounds. Twin durometer, or co-extrusion, is the combination of two or even more products of varying physical residential properties into a single extruded piece. An example would certainly be a stiff get rid of flexible fingers that might be made use of as a gasket or pillow.

Depending on the component intricacy as well as raw materials, one might estimate the prices beginning at much less than $1,000. Due to differing set up prices as well as run performances, we attempt to restrict the minimum production quantity to 1,000 lineal feet.

What Does Custom Plastic Extrusions Do?

We wish you located part one, sequel, and part three of our four-part collection on extrusion terms practical in comprehending numerous plastic account extrusion terminology. In component one of the series we reviewed extrusion sector terms you may listen to throughout conversations as well as in printed materials pertaining to extruders as well as tooling for the extrusion sector. In part three of the collection, we resolved product terms you may listen to extrusion providers speak about when they go over plastic materials. In the final blog on plastic extrusion terms, we are mosting likely to study processing terms you will likely hear a plastic extrusion vendor usage when chatting with you regarding the process.

What triggers the line. If you take a close take a look at an attracting for a plastic account with an intersection leg, you will see there is more mass in the location of the junction. Considering that polycarbonate products shrink some during the cooling process, the crossway of two legs cools at a slower price than the remainder of the account, causing it to diminish more as a result of the mass of the profile.

A tool developer would normally divide the flow of the two legs within the die, as well as permit them to find back with each other as the extrudate is being compressed to the front of the extrusion die. custom plastic extrusion manufacturers. This can sometimes develop a weld line where the 2 melt streams are brought back with each other so cautious tuning of the extrusion tooling is important to lessen this line.