An Fundamental Guide to Connection Assemblies: Categories, Applications, and Advantages

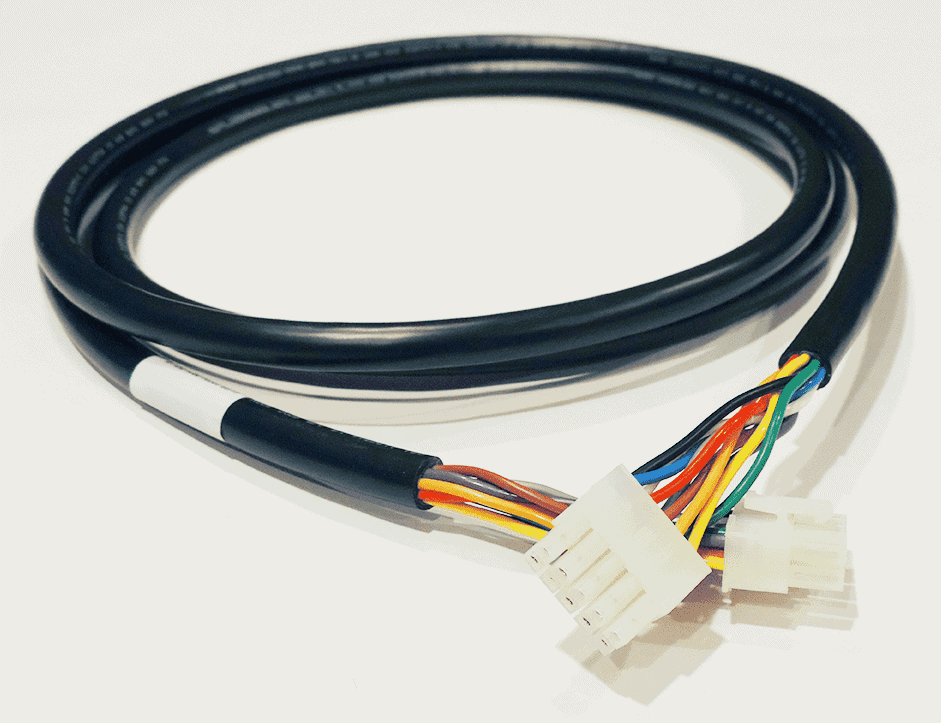

Cable assemblies play a essential role in a variety of sectors, serving as the foundation for electrical connections and information flow. These versatile components consist of multiple cables, connectors, and sometimes additional elements like insulation, all packaged together to ensure reliable and effective operation. With developments in technology and increasing demands for more compact, efficient solutions, the significance of cable assemblies has only expanded.

In conclusion, cable assemblies reduce the intricacy of cabling configurations by packaging different electrical and signal cables into a single, streamlined unit. This not only boosts structure but also cuts down on installation time and likely points of failure. Regardless of whether automotive uses, communication systems, healthcare equipment, or personal electronics, cable assemblies deliver a trustworthy means of connection that is essential for the functionality and longevity of electronic systems. Comprehending their types, uses, and advantages is key to enhancing any initiative that utilizes these vital components.

Types of Cable Assemblies

Wiring assemblies come in several types, each designed for specific applications and requirements. One widely-known type is the coaxial connector assembly, which consists of a central conductor, insulating layer, shielding, and an outer covering. Coaxial cable assemblies are frequently implemented in TV and internet connections, providing superb resistance to electromagnetic interference. They are crucial for high-frequency signal transmission, making them well-suited for media transmission and telecommunications.

Another favored type is the fiber optic connector assembly, which uses filaments of glass or plastic to transmit data as light signals. These assemblies are known for their high-speed data transmission capabilities and are more frequently used in telecommunications, internet infrastructure, and networking. Fiber optic assemblies are favorable for long-distance communication due to their low signal loss and immunity to electromagnetic interference, making them necessary in modern communication systems.

Moreover, power cable assemblies play a key role in supplying electrical power to different devices and systems. These assemblies typically include conductors protected with materials compatible for designated voltage and environmental conditions. Power cable assemblies are often used in industrial settings, electric vehicles, and renewable energy applications. They ensure reliable power distribution while managing the safety and functional requirements of the systems they serve.

Applications of Cable Assemblies

Cable assemblies find a multitude of applications across numerous sectors due to their critical role in linking and distributing power or signals between machines. In the car industry, cable assemblies are vital for linking components such as detectors, imaging devices, and control units, ensuring that vehicles run effectively and securely. These assemblies provide for everything from power supply to data transfer networks, showcasing their importance in modern vehicle engineering and performance.

In the communication sector, cable assemblies are vital for establishing interconnections between network devices, such as hubs, interconnects, and transmission lines. They enable reliable data transmission and connectivity, allowing rapid internet access and seamless connectivity. With the rising demand for more efficient communication networks, the role of cable assemblies in this area continues to grow, making them essential for both telecom companies and end-users.

The healthcare industry also benefits substantially from cable assemblies, where they are used to connect diagnostic equipment, scanners, and patient monitors. These assemblies make certain that critical medical tools operate precisely and securely, leading to better patient care and outcomes. As innovation advances, the demand for specialized cable assemblies in clinical settings continues to increase, driving innovation and enhancing the capabilities of healthcare devices.

Advantages of Using Cable Assemblies

Cable assemblies deliver significant advantages in effectiveness and management for every electrical or electronic project. By consolidating multiple wires into a cohesive, structured unit, cable assemblies reduce the time spent on installation and troubleshooting. This simplification not only speeds up the assembly process but also allows for easier identification of connections during maintenance, leading to lowered downtime.

Furthermore, cable assemblies give improved durability and protection for the wires themselves. They are often manufactured using materials that endure abrasion, chemicals, and environmental stress, which prolongs the lifespan of the connections. This kind of protection is vital in difficult conditions or applications where the cables might be exposed to movement or extreme temperatures.

Finally, using cable assemblies can significantly improve safety. By reducing the risk of loose or exposed wires, they help stop electrical shorts and other hazards. With appropriate insulation and design, cable assemblies ensure that installations comply with industry safety standards, providing peace of mind for manufacturers and end users.