An Comprehensive Manual to Accelerated Injection Molding Techniques Techniques

In the current rapid manufacturing sector, the need for quicker turnaround times and streamlined manufacturing processes has never been as essential level. Rapid injection-molding techniques has emerged as a significant solution, simplifying the manner products are created and launched.

This novel technique not just speed up the manufacture of plastic parts but additionally improves the agility and cost-effectiveness of manufacturing processes.

By utilizing advanced technological advancements and methodologies, rapid injection molding enables companies to reduce lead times considerably while ensuring high accuracy and standard in their outputs. This article delves into the essentials of rapid injection molding, investigating its benefits, implementations, and its impact on the product development cycle. Whether you're a experienced manufacturer or just new to the field, comprehending these advanced techniques can be the key to unlocking new possibilities in effective product manufacturing.

Grasping Swift Injection Molding

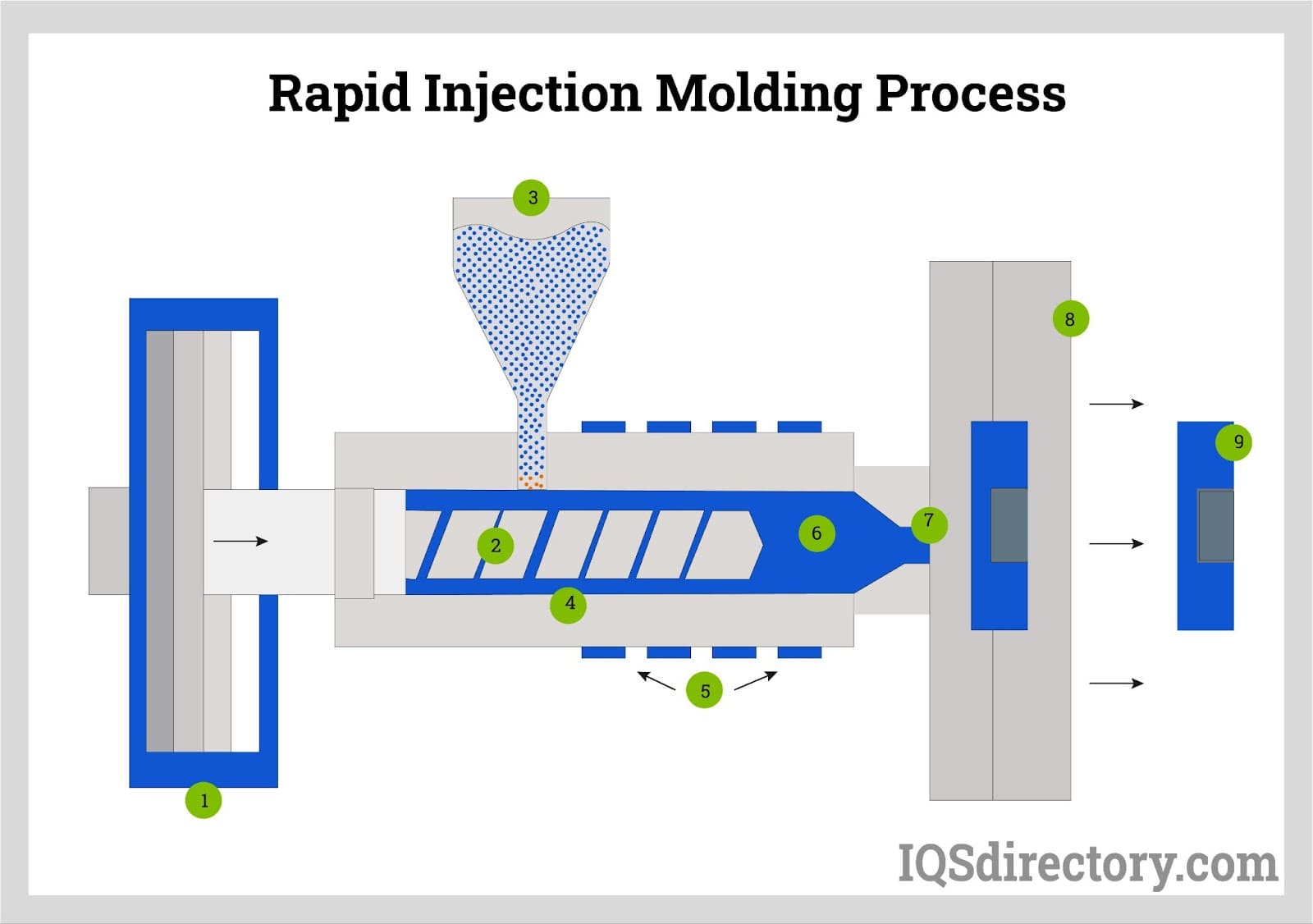

Rapid injection molding is an innovative manufacturing process that allows for the rapid production of plastic parts using injection molding techniques. It combines speed and efficiency, making it an optimal solution for developing prototypes and low to medium volume production runs. By employing advanced materials and efficient processes, manufacturers can produce premium components in a limited amount of the time compared to traditional molding methods.

The essence of rapid injection molding lies in its ability to cut lead times considerably. This is achieved through the use of rapid tooling, which involves the creation of molds using materials that can be produced quickly and more economically. These molds typically have reduced design and production cycles, allowing faster turnaround times for both prototyping and production. This adaptability makes rapid injection molding particularly appealing to businesses looking to reduce their product development timelines.

Moreover, rapid injection molding is ecologically friendly, as it limits waste and recirculates materials effectively. The process allows for increased design flexibility, enabling engineers to make iterative changes quickly based on feedback during the development phase. This method not only boosts productivity but also certifies that the final products meet the specific specifications needed for market success.

Benefits of Rapid Plastic Molding Molding

Accelerated injection delivers substantial quickness benefits, allowing manufacturers to manufacture mock-ups and end-use parts much rapidly than standard processes. This rapid response time is essential for companies endeavoring to test designs and launch products to market swiftly. By utilizing cutting-edge technologies and efficient processes, businesses can improve on their designs much productively and react to market requirements with agility.

Cost-effectiveness is an additional key advantage of fast-track injection. Production runs can be started with diminished upfront costs compared to standard molding, especially for minimal to average volume projects. The ability to promptly manufacture molds diminishes the time and labor costs associated with extensive manufacturing processes. As a consequence, businesses can realize a favorable return on investment, making accelerated injection an attractive option for multiple applications.

Additionally, rapid molding ensures superior levels in the fabrication of parts. The contemporary materials and processes used in this approach ensure that final products exhibit superb surface finishes and narrow tolerances. This reliability in quality is vital for fields such as automotive and healthcare, where precision and reliability are paramount. As a result, companies can rely that their products will satisfy or exceed customer requirements, improving brand standing and edge in the field.

Applications and Sectors Using Rapid Injection Molding

Accelerated injection molding is widely adopted across various industries, enhancing the effectiveness of goods creation. In the motor vehicle industry, producers utilize this technique to produce prototype components and intricate components quickly, allowing for quicker design iterations and reduced time to market. The capability to make adjustments rapidly means that groups can react to design challenges or consumer demands without the lengthy lead times associated with conventional molding processes.

The consumer technology industry also gains significantly from rapid injection molding. With the constant advancement of technology, companies must to deliver innovative solutions to the marketplace at an unprecedented pace. Accelerated injection molding enables the production of high-quality housings, buttons, and connectors in a brief timeframe, allowing rapid turnaround and customization options that meet specific consumer needs. This agility is essential for staying competitive in a fast-moving industry.

Furthermore, the healthcare industry utilizes accelerated injection molding for making medical devices and components, such as enclosures and connectors, with strict regulatory requirements. This technique enables manufacturers to create small runs of specialized parts efficiently, guaranteeing that they can meet both functional and compliance standards free from the expenses related with full-scale production. The precision offered by accelerated injection molding is crucial for guaranteeing the dependability and security of healthcare devices.