Alumina disc: a shining pearl in materials science and a pioneer in high-performance applications

TRUNNANOIn the vast starry sky of materials science, aluminum oxide disk, with its unique physical properties and a wide range of application fields, is like a bright pearl, leading the development trend of high-performance materials. This paper compares the performance advantages, preparation technology, and application of alumina discs and reveals their important position in modern industry with similar materials.

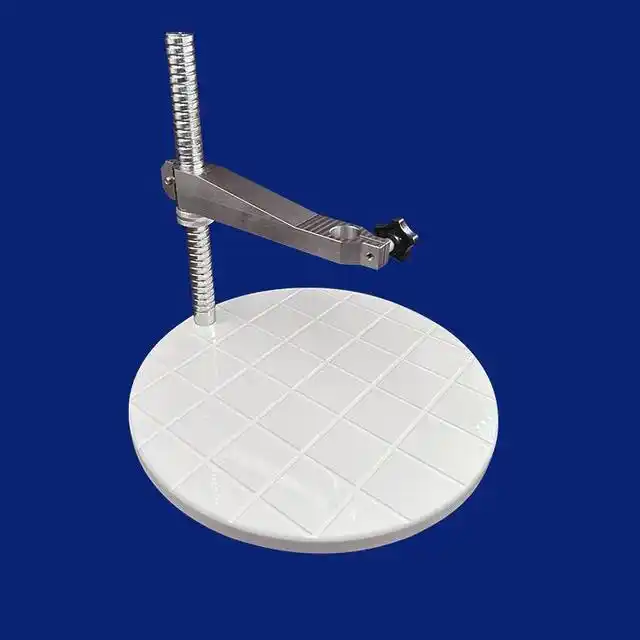

TRUNNANO Alumina Disc

Alumina disc: The cornerstone of superior performance

Alumina (Al₂O₃), one of the most common oxides on Earth, exhibits extraordinary mechanical strength, high thermal stability, and excellent wear resistance when it appears in disk form. These properties make alumina discs the material of choice for many high-tech applications.

Mechanical strength: Alumina discs have an extremely high hardness, second only to diamond and cubic boron nitride. They can withstand extreme mechanical stresses, ensuring stability under high-speed rotation or heavy load conditions.

Thermal stability: Alumina's very high melting point (about 2050°C) and good thermal conductivity allow it to maintain good mechanical properties and chemical stability in a high-temperature environment. This makes it the ideal material for high-temperature stoves, heat exchangers, and other equipment.

Wear resistance: The alumina disc's surface hardness and wear resistance are high. It effectively resists wear and scratches and extends service life, making it especially suitable for precision machining and polishing.

Preparation process: integration of science and technology and art

The preparation of alumina disks is a complex process integrating material science, mechanical engineering, and precision machining. The main methods include powder metallurgy, sintering, and sol-gel.

Powder metallurgy: Through the high purity alumina powder molding, sintering at high temperature to form a dense disk structure. This method can precisely control the composition and microstructure of the disk to meet specific application requirements.

Sintering method: Alumina powder is used in a specific atmosphere and temperature under the biochemical reaction to form a dense ceramic disc. Controlling temperature and time is significant in sintering, directly affecting the disc's performance.

Sol-gel method: The alumina sol is obtained by chemical synthesis, and then the disk is prepared through gelation, drying, and sintering. This method is suitable for preparing alumina disks with complex shapes and microstructures.

Applications: From precision manufacturing to aerospace

With its excellent performance, alumina disks shine in many fields.

Precision manufacturing: In the semiconductor industry, alumina discs act as wafer-bearing discs to ensure high precision and flatness during chip processing.

Aerospace: Due to its lightweight, high strength, and high-temperature resistance, alumina discs are the material of choice for key components such as rocket engine nozzles and thermal protection systems.

Medical field: In biomedical engineering, alumina disks make medical devices such as artificial joints and dental implants because of their good biocompatibility and corrosion resistance.

TRUNNANO Alumina Disc

Comparison with similar materials: What are the advantages?

Materials similar to aluminum oxide disks include silicon carbide (SiC) disks and Silicon nitride (Si N₄) disks. These disks also have high hardness, thermal stability, and good wear resistance, but each has its characteristics in specific application scenarios.

Silicon carbide disc: Although silicon carbide has higher hardness and better thermal conductivity, its cost is higher, and it is not as stable as alumina in high-temperature oxidation environments.

Silicon nitride disk: Silicon nitride disks have excellent thermal shock resistance and a low coefficient of thermal expansion, making them suitable for applications with extreme temperature changes. However, their corrosion resistance is not as good as alumina's in some corrosive environments.To sum up, alumina discs stand out among many high-performance materials with their balanced performance, broad applicability, and relatively economical cost, becoming an integral part of modern industry. With the continuous progress of materials science and the constant expansion of application fields, alumina disks will show their unique charm and unlimited potential in more fields and contribute to the improvement and development of human society.

Supplier

TRUNNANO is a globally recognized manufacturer and supplier of compounds with more than 12 years of expertise in the highest quality nanomaterials and other chemicals. The company develops a variety of powder materials and chemicals. Provide OEM service. If you need high quality Alumina disc, please feel free to contact us. You can click on the product to contact us. (sales5@nanotrun.com)