All You Need to Know About Laser Cutting

When it comes to cutting essence, wood, glass, and other hard shells, it's hard to imagine Laser radiation of light being suitable to keep up with a spinning blade. A traditional laser beam of light would indeed have a tough time. That said, a concentrated laser makes cutting a breath.

What's laser Cutting?

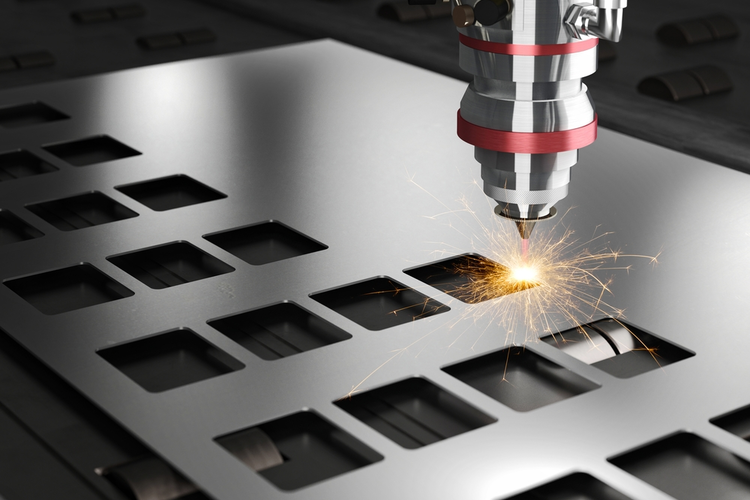

A laser cutting is a process where a beam is used to heat a workpiece to the point where the piece is precisely disassociated. According to Answers.com, laser machines include a high-powered laser beam and a computer to direct the laser onto the material to be cut. From there, the laser melts, vaporizes, or burns the material along the destined cut line, performing in a precise, neatly abbreviated edge.

According to Coherent, a company that manufactures Laser cutting London machines, and laser cutting:

.". concentrates high quantities of energy into a small, well-defined spot. The performing heat energy created by the beam vaporizes accouterments in this small-defined area and gas, or admixture of feasts, similar as oxygen, CO2, nitrogen, and/or helium is used to blow the wracked material out of the indentation (the range of a groove made by the laser). The laser's energy is applied directly where it's demanded, minimizing the Heat Affected Zone (HAZ) girding the area being cut."

Laser Cutting Operations

Laser cutting is used by manufacturers, small businesses, seminaries likewise. According to Coherent, common particulars suitable for the laser machines include

Thin non-metal equipment- Paper, utmost plastics, fabrics, mylar stencils, polycarbonate, wood up to .04 Inches, and thin acrylics can be cut with a 150-watt average power (450-watt peak power) ray.

Thicker non-metal equipment- You will need a laser beam with an average power of between 250 to 500 watts (up to 1500 watt peak power) to cut thicker non-metal material similar to thicker plastics and wood over to one inch thick. In general, lower power spotlights will have to work harder to make the same cut. This reduces cutting speed and can affect in inordinate heat, chemical changes, or damage to the Heat Affected Zone.

Metal equipment- Metal equipment generally bears advanced power spotlights (between 150 and watts (up to 2500 watt peak power). Some thin metal (similar to a pristine sword or cold-rolled sword) can be cut with 150-watt spotlights when oxygen- help gas is used.

Laser cutting East London is used to cut any number of particulars from a variety of materials similar as jigsaw mystifications, timepiece faces, metal tags, ministry corridor and factors, packaging, signs, patterns, leather upholstery pieces, and more.

Advantages of Laser Cutting

Laser offers multitudinous advantages over other types of cutting. Not only can you cut a variety of materials similar as paper, plastics, cardboard, leather, and metal, the laser is extremely precise. Once a pattern is programmed into the ray knife, it can continuously cut exact clones of the pattern on the workpiece after workpiece. Ray cut edges are clean. In addition to cutting particulars, ray can also cut small, largely detailed holes with good edge quality.

Original Source: Laser Cutting Company London