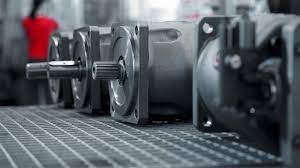

All You Need To Know About Hydraulic Pumps

Vaishali AegisThere are a wide variety of pumps used in day-to-day activities. These pumps are operated on various means; some are operated mechanically, and some by fluids. Hydraulic pumps play a vital role and offer high efficiency when operated.

What are hydraulic pumps?

Hydraulic pumps conjointly referred to as a pump, is a machine that converts the mechanical energy of the rotating blades into the pressure energy of the water. This pressure energy helps the water reach high altitudes wherever it's kept in an overhead tank or pumped up to ground level for varied functions like irrigation, cleaning, drainage.

Inside the diesel engines with hydraulic pumps casing, vane blades rotate at high speeds, which causes water to exert force because it pushes towards the border of the casing. For one purpose, the water enters the delivery tube that is an increasing diameter tube. The reason for this can be that, per Bernoulli's principle, because as the space will increase, speed decreases; however, the pressure head will increase.

Therefore, this can be wherever mechanical energy is reborn to pressure energy.

Where are hydraulic pumps used?

Hydraulic pumps find uses in really each hydraulic force transmission framework. A hydraulic siphon may be a convenience that changes over mechanical vitality into hydraulic vitality, a mix of weight and steam.

An essential hydraulic siphon is a hand siphon employed for any low force application wherever a central player is either to a fault, expensive or inaccessible. A pump used for helper power, for instance, to discharge hydraulic brakes on a piece vehicle towed ranch execute. Then again, a pump is used because of the essential hydraulic supply, for instance, with hydraulic force apparatuses or on benchtop hydraulic passes.

Since the force input is low (most people have no equipment for accomplishing in way over a tenth of a pull for in way over a few moments), pump applications are extraordinarily moderate even though weight maybe 10,000 psi and a lot of noteworthy.

Diesel engines with hydraulic pumps have a mechanical contribution from an inward burning motor or electrical engine. These central players input their mechanical capability to the hydraulic siphon during a movement manner.

The information shafts of the siphon will be related to riggings, vanes, or cylinders of the hydraulic siphon, wherever they're going to pivot or reply to move pressure(power) to the hydraulic liquid. For no matter the length of your time that the ability created by the siphon is sufficiently high, the stream can happen at speed directed by the relocation volume of the siphon and also the speed at which it rotates.

How do hydraulic pumps work?

● There are two types to work for hydraulic pumps:

● Centrifugal pumps

Centrifugal pumps work by force; when the pump's vane rotates unceasingly, it develops the force that brings the water from the sump or well to the pinnacle tank. Centrifugal pumps employ prime delivery heads with high discharge.

● Reciprocating pumps

Diesel engines with hydraulic pumps work by the reciprocator force; a cylinder with a piston rod connects to a crank; this crank connects to the wheel. When this wheel starts rotating through an electrical motor, the crank starts moving forward and backward; this piston conjointly moves forward and backward.

By moving unceasingly, there develops some reciprocator force that sucks the water from the sump. When a piston moves backward within the cylinder; that is, water enters into the cylinder. When the piston moves forward, the water within the cylinder moves into the delivery pipe; likewise, continuous water delivers to the desired head. A reciprocatory pump employ for low head delivery with low-rate flow.

Classification of hydraulic pumps

● Cylinder pumps

Piston pumps are the foremost common and the foremost capable of advanced employment. These are the hydraulic pumps you're well on the way to discovering in grouping things. They're the pumps you may use in high-pressure applications. A cylinder siphon may be a positive dislodging siphon that utilizes high-pressure steel operating correspondingly with a cylinder to move water.

● Vane pumps

These are uncommon and straightforward pumps that you can use for lower pressure applications for prime stream rates.

Vane pumps are specific uprooting pumps that will work with varied vanes and convertible vanes, swinging vanes, moving vans, outer vanes, and slippy vanes. Because the engine rotor rotates, it vanes clear fluid to the contrary aspect of the pit within the engine and crushes it through unharness openings within the cam.

● Apparatus pumps

The foremost primary diesel engine with hydraulic pump siphon you'll utilize. You may commonly utilize this siphon for single, basic applications. Apparatus pumps work by utilizing two riggings that are employed to uproot water. The riggings rotate along, making attractions separate, bringing water into the siphon - water it uproots when the apparatuses work along.

Difference between hydraulic pumps and motors

● Hydraulic pumps are the elements that absorb mechanical energy to supply hydraulic energy. Hydraulic motors are simply the other.

● Hydraulic pumps connect with the first cause, and also, the pump shaft has no further radial load, whereas motors connect with the load, like sprockets, pulleys, gears. Its central shaft can bear the next radial load.

● The pressure of the hydraulic pump is low to boost the oil absorption performance and anti-cavitation ability. The suction nozzle is sometimes more significant than the air mass nozzle; however, the hydraulic motor has no such.

Conclusion

As per diesel engine with hydraulic pumps, the hydraulic pumps can lead to failure due to:

● Excessive heat: Overheating in the hydraulic system could damage seals, degrade the hydraulic fuel.

● Aeration: Air could cause problems when put under pressure by the pump.

● Cavitation: Happens when fuel does not fully take up space in the pump because of unusual high fluid viscosity.

● Over pressurization: Sensitive machines should be under the correct pressure based on the recommendations.