All You Need To Know About Forged Steel

Inovacast

The steel forging suppliers started to create different sorts of end materials with unmistakable properties in the old times. In advanced times, machines and pressure-driven mallets enable the producing strategies to manufacture steel and different metals. Turning the pages back to the noteworthy ages, a forge smith was the hero in assembling early sorts of produced steel. He utilized water to wet the metal and afterward strike it over an iron block utilizing a producing hammer. Persia and China were the primary spots where the manufacturing system made its preeminent strides. Contemporary strategies then, at that point, fired, getting down to business and acting during the 1800s.

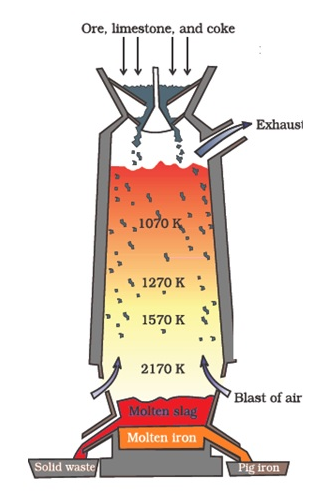

The process of manufacturing steel

When steel forging is warmed to producing temperature, it becomes bendable and pliable and be formed to a state of our decision by applying pressure. With legitimate handling strategies, steel manufacturing permits a billet of steel to be molded for all time without breaking because of its pliancy.

Steel manufacturing needs an enlistment warming framework, produce heater, or fashion stove to warm the steel to an adequate temperature. Metallurgical recrystallization and grain refinement result from the warm cycle and the deformity interaction. This reinforces the subsequent manufactured steel item, especially the sturdiness. It's abnormally agreeable to see a goliath square of steel get crunched and formed.

Properties of forged steel

Its unique properties differentiate forged steel from other treatments such as casting:

- Forged steel has great strength, increased hardness, and first-class durability. When in contact with other substances, it is very unlikely that the steel will break.

- It is possible to maintain the same consistency in all steel forgings manufactured, as the forging process is quite thorough and measured.

- There is a limit to the thickness and size of steel that can be forged, as metal forming is a rather tedious job.

- Steel forging is generally used in mechanical and industrial applications due to its strength and availability and specialized alloys such as stainless and carbon steel. Steel forging offers unsurpassed strength for the manufacture of parts.

Steel manufacturing can be ordered into three classes relying on the shaping temperature:

(1.) Hot Forging of Steel

The producing temperature is somewhere in the range of 950 and 1250 degrees Celsius over the recrystallization temperature. It brings about great formability and requires low framing powers.

(2.) Warm forging of steel

The forging steel forging suppliers' temperature is somewhere between 750 and 950 degrees Celsius. It prompts restricted formability and requires higher framing powers than for hot manufacturing.

(3.) Cold forging of steel

The producing temperature is at room condition, self-warming up to 150 degrees Celsius because of the framing energy. It brings about low formability and needs high shaping powers.

The properties of forged steel

Forged steel separates itself from different medicines like projecting. The properties of forged steel are very interesting when contrasted with cast steel. We should check a portion of the produced compound steel properties:

- Strength

Steel forging comprise astounding strength, more prominent sturdiness, and first-rate toughness. In contact with different substances, the steel is more opposed to breaking.

- Consistency

The manufacturing system is very meticulous and estimated, and one can keep up with similar consistency in all the steel forgings made.

- Range

There is a breaking point in the size, and the thickness of the steel that can be manufactured as molding the metal is seriously monotonous work.

History of forging

Smiths have practiced forging for thousands of years. At first, bronze and copper were the most common forged metals in the Bronze Age. Later, as the ability to control temperature and the process of smelting iron was discovered, iron became the primary forged metal. Traditional products include kitchenware, hardware, hand tools, and edged weapons. The Industrial Revolution allowed forging to become a more efficient mass-production process. Since then, forging has evolved with advances in equipment, robotics, electronic controls, and automation. Forging is now a worldwide industry with modern forging facilities producing high-quality metal parts in a vast array of sizes, shapes, materials, and finishes.

The categories of forged steel

Diving deep into the science, steel manufacturing can be ordered into two fundamental sorts:

(1.) Open die forging

In open kick the bucket steel forging suppliers, the metal piece goes through a misshaping between different passes that don't encase the material altogether. The kicks the bucket continually hammer the metal to accomplish the ideal shape.

(2.) Closed die forging

In the shut bite the dust procedure, the metal is squeezed between two kicks of the bucket that involves the pre-cut profile of the ideal shape.

The significance of forged steel

The reward of manufactured steel is that the metal becomes more grounded than comparable projected or machined kinds. Steel manufacturing is normally utilized in mechanical and modern applications because of its solidarity, accessibility, and specific amalgam types like hardened and carbon steel. Forging steel offers magnificent versatility for assembling parts that don't fizzle. The different advantages of forging are:

- Steel forging parts offer a more significant level of unwavering quality and resilience capacities.

- Steel forgings offer consistency of arrangement and design. They have the least variety in machinability and mechanical properties.

- Forged steel parts are more grounded and solid than machined or cast parts.

- Steel forgings cause potential plans that oblige high loads and stresses.

- Steel forgings are utilized when quality can't be addressed.

- Steel produce parts are liberated from gas voids, pockets, or cooling surrenders, prompting burden disappointment.

The applications of forged steel

The attributes of produced steel, for example, strength and obstruction, benefit each industry from auto to farming hardware and assembling. Steel forgings fill in as line fittings in the oil and gas industry though as pulleys and stuff wheels in the car business. The airplane business benefits from the strength of fashioned steel in their clasp and airframe individuals.

Conclusion

Forged steel suppliers are fostering the main environment in the weighty business, which permits customers to proficiently oversee and mechanize their stock chains utilizing electronic devices and administrations. They are focused to decrease the secret danger in esteem chains by giving important data, from consistency to quality affirmation, making an incentive for all partners.