A Role of Precision Metrics and Specs in High-Precision Cutting

In the realm of manufacturing cutting and fabrication, exactness is of supreme importance. Whether it involves sensitive components for space applications or sturdy structures for automotive assembly, the precision of cuts can greatly impact general performance and safety. As sectors strive for efficiency and reliability, understanding tolerances and specifications becomes essential in ensuring that the final products meet strict quality standards.

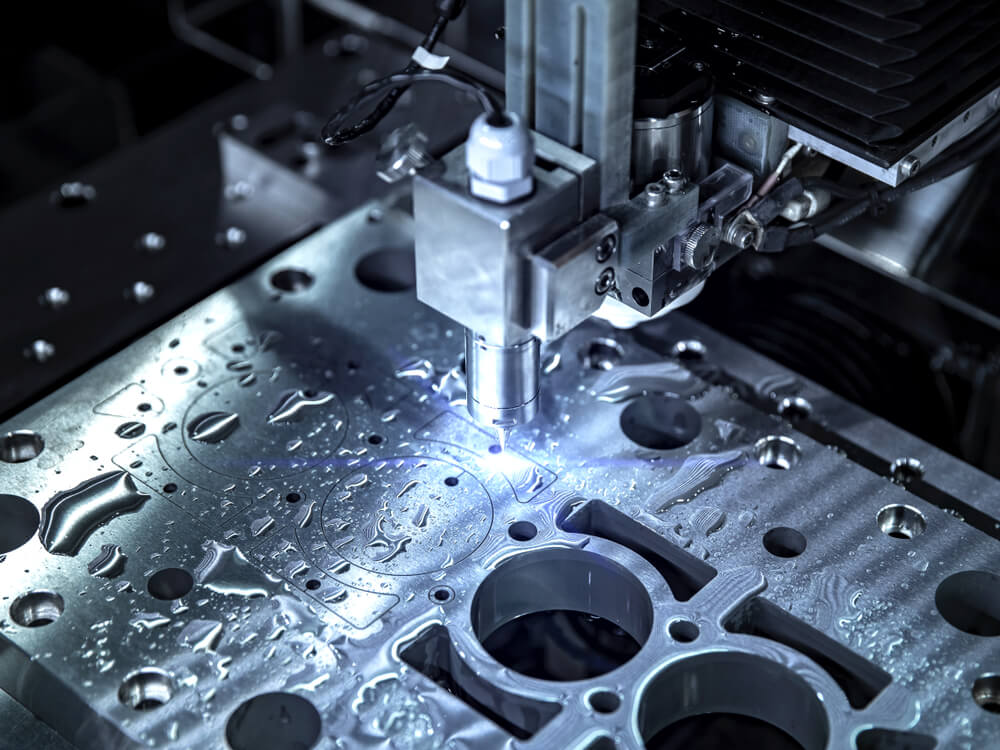

In this scenario, advanced trimming technologies like light beam and waterjet cutting services play a pivotal role. These methods not only deliver unmatched precision but also allow for the effective handling of a wide variety of materials. By adhering to exact tolerances, manufacturers can achieve consistent results that improve product integrity, maximize material usage, and ultimately foster innovation in various sectors. The integration of these technologies, along with well-defined specifications, marks a major evolution in how we approach manufacturing cutting today.

Understanding Allowable Variations in Cutting

Allowable variations play a vitally important role in the precision cutting processes used in commercial manufacturing. They specify the allowable variations in dimensions and guarantee that parts assemble correctly during assembly. In applications such as optical and hydraulic jet cutting services, sustaining tight tolerances is crucial to achieve the intended performance and operability of components. These criteria guide manufacturers in selecting the appropriate cutting methods and materials, contributing to overall quality of the product.

In laser cutting, for example, the precision is often defined by the beam quality and the focus of the laser. This control permits very small tolerances, which is particularly important in fields like aerospace and medical devices where precision is of utmost importance. On the contrarily, waterjet cutting can handle different tolerances due to its method of cutting with pressurized water. Understanding the specific tolerances required for each use case helps manufacturers choose the most appropriate cutting technology.

Additionally, communication of tolerances between engineers, designers, and manufacturers is essential. Clear documentation of standards guarantees that all parties involved understands the requirements, reducing the chance of errors. By establishing proper tolerances at the design stage, manufacturers can leverage advanced cutting techniques effectively, leading to improved efficiency and reduced waste in the production process.

Specifications for Laser Cutting

Laser cutting is famous for its precision and flexibility in production applications. To achieve ideal cutting results, specifications such as the type of material, material thickness, and laser power settings are essential. Commonly cut materials include metal, plastics, and wood, each requiring different laser settings. For instance, thin metals may require reduced power settings, while heavy materials necessitate higher intensity to ensure complete penetration.

Another key specification involves the cutting speed, which influences both the standard of the cut and the overall efficiency of the process. A quicker cutting speed may boost production rates but can lead to reduced cut quality and accuracy, particularly in complex designs. Conversely, slower speeds typically produce more detailed details but at the cost of time. Finding a compromise between speed and quality is crucial for manufacturers looking to maintain standards of excellence in precision cutting.

Finally, the focal point of the laser beam is a crucial specification that affects cut quality. The focal point must be accurately adjusted to match the thickness of the material and type of material. An incorrect focus can result in excessive heat, which may lead to warping or damage of the material. Thus, fine-tuning the focal length is a necessary part of the setup process, crucial for achieving clean, accurate cuts in various industrial applications.

Specifications for Waterjet Cutting

Water jet cutting is a very versatile technique that allows for precise cuts in a wide range of materials, from metals to plastic. One of the most critical specifications to consider in waterjet cutting is the thickness of the material being cut. Waterjet systems can usually handle materials up to several inches thick, though the maximum thickness can vary based on the individual machine and the type of material. Additionally, the pressure of the waterjet, often greater than 60,000 psi, plays a critical role in obtaining clean edges and exact dimensions.

Another key specification is the tolerances attainable with waterjet cutting. The process can usually achieve tolerances of ±0.01 inches, making it suitable for applications requiring high precision. However, the actual tolerance can vary on factors such as the material type and the cutting speed. Incorporating appropriate tolerances is important when designing components that must fit together or be assembled, ensuring that all parts meet the required specifications for functionality and appearance.

Lastly, the choice of abrasives and nozzle design greatly impacts the quality of the cut and the overall efficiency of the waterjet cutting service. Different abrasives can be used depending on the material and desired finish, while nozzle design can influence the width of the kerf and the smoothness of the cut edges. Comprehending laser and waterjet cutting service enables manufacturers to optimize their cutting processes and achieve the desired results while maintaining cost-effectiveness and productivity.