6 TIPS for writing a proper Inspection and Test Plan (ITP)

Randall Stremmel6 TIPS for writing a proper Inspection and Test Plan (ITP)

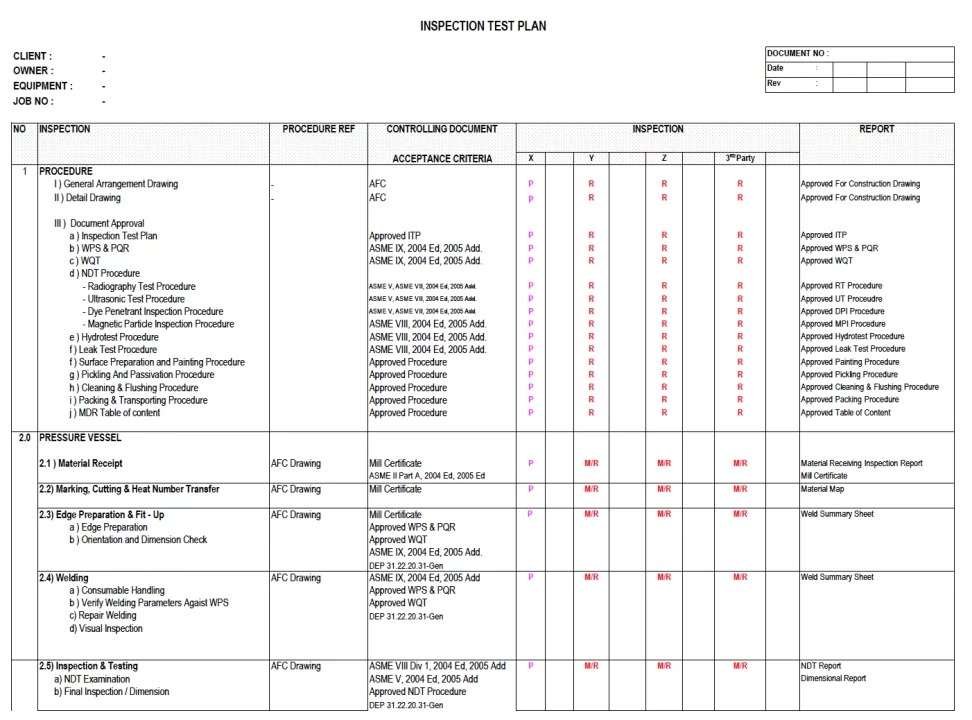

Inspection and test plans are probably the essential documents for the Quality Control of a construction project.

A precise, robust, and concise ITP will make things on site easy. It will define each party’s responsibilities during the works, and after all, it will be the “Bible” for compiling the As-Built Packages at the end of the works.

Furthermore, the ITP is the primary document that will plan and manage the test/inspection activities for providing assurance, control, and documented evidence over the constructed works.

This item is something that would make your clients happy.

Starting the work without an (at least one ITP submitted to the Project Manager for approval) Inspection and Test Plan is an extremely non-recommended practice and a clear nonconformity in many contracts.

During the last 20 years, it has been a significant change in the industry regarding Health and Safety Management. The existence of a Method Statement before the commencement of the actual work on-site is now (more or less) standard practice in every construction project.

Can we say the same thing about the ITPs? Not exactly…

So, here are 6 Tips to keep in mind when writing an ITP.

TIP 1:

Every ITP should follow (as much as possible) the sequence of the works that are detailed described in the Works Method Statement. The contractual requirements for tests and frequencies should be precise. In the case of non-clarity, the contractor should issue RFIs (Request for information) from the Client.

TIP 2:

The ITP should have explicit references to the Documents that specify the requirements. If possible, even the specific clauses should be referenced.

TIP 3:

The responsibilities (Hold Points, Witness Points, Review Points, etc.) for each test/inspection should be established before the works start. Otherwise, there will be confusion and compromises from all the parties.

TIP 4:

You will need a system to invite the Client to witness the inspections. It is essential that the Client or Client’s representatives on-site are timely informed about seeing and sign-off the relevant forms.

TIP 5:

The ITP should clearly state and also have as attachments every form, check sheet, and other records that need to be completed during the inspection.

TIP 6:

ITP’s are living documents, and what this means that you shouldn’t be afraid to add or subtract steps, hold points, etc. It needs to be a clear record of finished actions, in progress steps, and future operations.

TIP 7:

Expect that something will change, issues will arise, or repairs/modifications will happen in the process of fabrication. For example, advice 7 in a document that says six tips, things change, so document it.