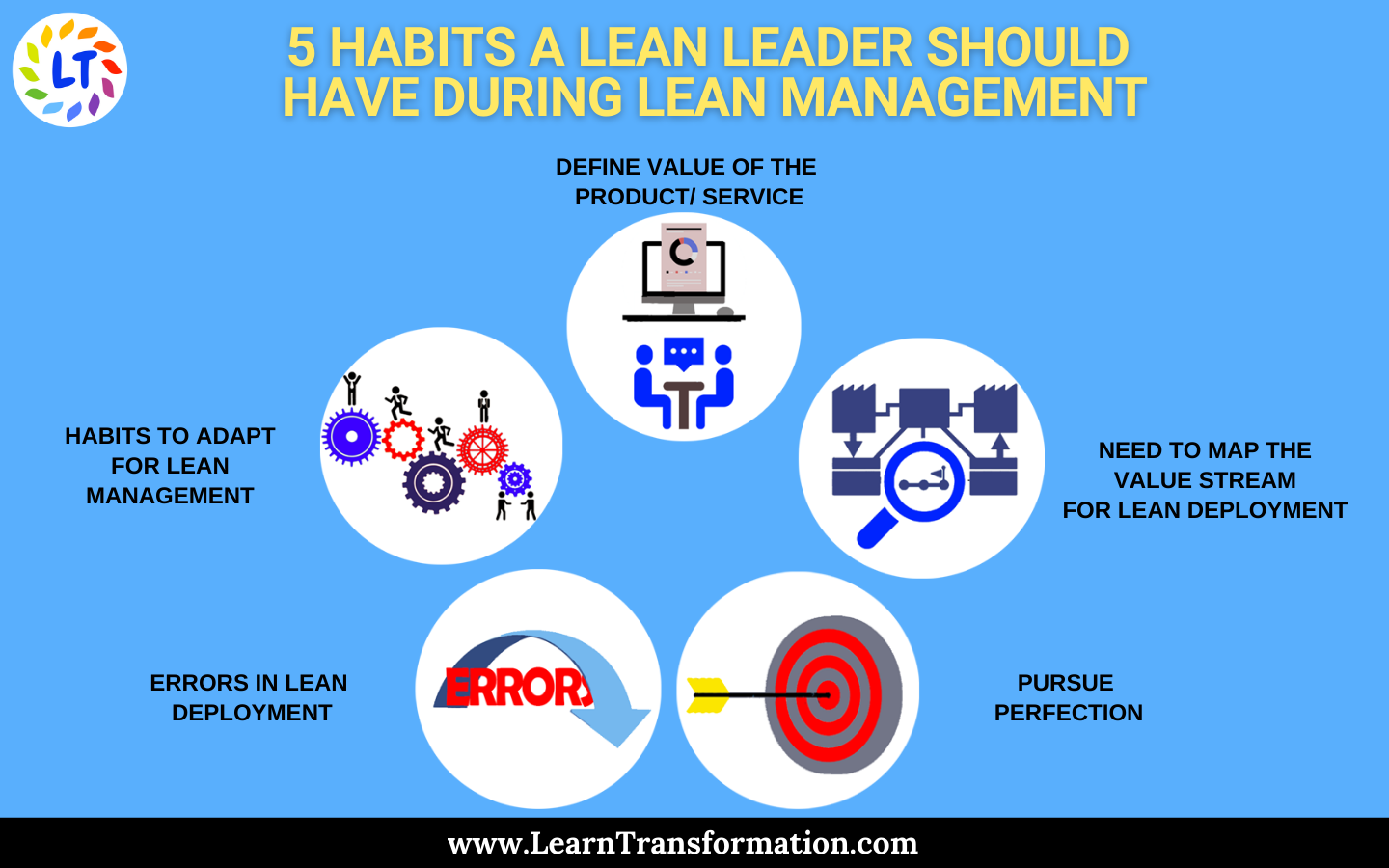

5 Habits a Lean Leader should have during Lean Management

Lean is a way of thinking, leading, planning and stepping towards the success of an organization. It is intense on enhancing safety, standard, transport, cost, operational excellence, customer excellence and employee’s morale in an organization.

Lean Management and Lean Manufacturing have extended its arms over the past few decades to take its applications in different areas, like: Healthcare, Service Sector (retail, travel, etc.), Government Services, IT & Software Development and growing Startups.

Lean is something that transforms the way of working and processing of the company. It leads to long term efficient strategies for business improvement. Lean not only benefits the company but also leads to personal and emotional growth and provides a new way of working to the team. It gives new shades to leadership and creates sustainable business success. In Lean management continuous improvement is also known as Kaizen.

The concept is to maximize the customer value with minimum waste, i.e. producing more with less.

Lean was born out of manufacturing practices but in digital transformation has molded into the world of knowledge, work and management. For example, it encourages the way of the Toyota in which the key statues (both interconnected) are:

- Continuous improvement

- Respect for people

Handpicked for our Leaders: What exactly is Digital Transformation in 21st Century?

Every Employee Deserves Respect. Mutual respect between leaders, staff, and customers is needed to create an environment of continuous improvement in a company. This ingredient of mutual respect leads to everyone’s engagement in their improvement efforts with the belief that everybody takes pride in doing the work. Lean Leader strive to make continuous improvement in team’s jobs, encouraging their subordinates to improve their work in order to cater the highest quality goods and services at the lowest cost with safety and contentment to the customers.

Following are some key points a Lean Leader should kept in mind during Lean Management.

- Habits to adapt for lean Management

- Meet with your team regularly

As the leader of the team, you should be available for them at all times. Lean Management encourages leaders to be more interactive as it would give them opportunity to sync progress on crucial steps. Leaders should discuss any potential blockers and get solutions for it. To improve the Lean environment, leaders need to be part of the team, not a figure high above it on a throne.

- Observe process and progress on regularly

Being updated about the flow of work across the process can help leaders be a more effective coach and point out room for improvement in team as here they need to be more of a teacher than a commander. Leaders should keep a close eye on workflow analytics and look for ways to improve company’s value stream.

- Provide feedback

Leaders should to give credit when it is worthy to their subordinates and alert team members when their performance starts to slide down the ladder of progress. Appreciate them in public but correct them in private. A lean leader must ask clarifying questions that will either help to understand the idea further or give way to the team by giving them a way to reach the conclusion on their own.

- Patience is the key

Lean is not a task that will be over once it is done. It needs to be adapted in your personality. And here, patience is the key. Lean Transformation is a path of progress built by giving way to improvements. The patient does not move further until the next step is ready. They know that it is worth the wait.

Whenever we are moving towards the road to our destination, in between the journey many unnecessary pleasures come our way which can hinder or slow our journey.

- Whenever we feel that our growth has been hindered then we should ask ourselves that, why did we start this journey in the first place? Because, when we have got a strong answer to that why, nothing can stop us.

- After the ‘why’ we should ask how we will reach our destination. As that ‘how’ is going to be our next step. The first question will keep you motivated and the second will tell you that there is a long way to go so you cannot stop. Here lean gives a push to the journey.

Patience is a must lean leadership virtue. Sure, there are things you can do to accelerate improvement, but this change will not happen overnight and it will never be finished as sky is the limit. So, don’t stop.

2. Define Value of the product/ service

Value is what the customer is willing to pay for a product. It is root to discover the actual needs of the customer. Sometimes customers may not know what they want or are unable to implement it. This is especially common when it comes to new products or technologies. There are many techniques such as interviews and web analytics that can help leaders discover what customers find valuable and what waste. By using qualitative and quantitative techniques leaders can unfold what customers want from the product or service and the price that they can afford.

Lean aims at continuous improvement but the problem with it is that it is cumbersome to sustain with traditional leadership tactics that depend heavily on autocratic leadership and micro-management. Lean manufacturing is about eliminating waste thus waste identification and its removal is poignancy in lean philosophy. Through lean, processing can be attained by using less human effort, less space, less financial resources for producing the same good with more customer satisfaction as all this would reduce overall product prize.

3. Need to map the Value Stream for lean deployment

Learn transformation guides leaders in identifying and mapping the value stream. Here, the idea is to utilize the customer’s end value as a root point and identify all the activities that bestow to these values. Activities or processes which do not add value to the end customer are considered waste.

The junk can be bifurcated into two types:

- Non-value added but necessary waste

- Non-value added and unnecessary waste.

The later is pure scrap and should be eradicated while the former should be reduced as much as possible.

Handpicked for our Leaders: What exactly is Digital Transformation in 21st Century?

Some techniques for making sure that value-added activities augment is by breaking down steps of processes, distributing and equalizing the work, rising cross-functional departments and training employees to be multi-skilled and adaptive for all processes. Even processes that don’t appear broken into steps can be improved. Kick the traditional bucket aside and let the advancements flow. Leadership requires leaders to ask questions and rebuild processes. It demands ardent curiosity, creativity and readiness to take risks.

- By reducing and annihilating unimportant processes, leaders can ensure that customers are getting exactly what they want while at the same time reducing the cost of producing that product or service.

- The best processes are simple. Leaders should come up with ways through which wastes can be reduced by simplification of processes. Some people tend to believe that enhancement is about doing more and adding more, leaders need to set this thought aside and guide their team towards a better change. Preach your team to work smarter, not harder.

- Markets have become customer oriented. And customers don’t want to give their hard-earned money for defects, delays or unnecessary inventory so leaders must try to reduce them. Lean is not just about cutting costs. The key here is to spend money on what you need in order to provide higher customers satisfaction – avoid spending in areas that add no value.

4. Errors in lean deployment

One way of pursuing lean planning is needed, which will be useless, if implementation is not good. So, avoid mistakes in implementation including:

- Setting expectations for Lean too high or setting goals that are outside the scope and control of the team

- Losing vision of business goals

- Playing politics and dirty games when implementing Lean

- scarce executive buy-in

- Traditional people in management may refuse to participate in Lean implementation

Further are the albatross around the neck for lean deployment

- Lack of a plentiful taste of urgency or allowing too much satisfaction.

- Lack of a powerful guiding alliance.

- Lack of a vision

- Extreme neglect of communicating the vision. .

- Deficiency to create short-term wins.

- Announcing victory/success too early.

- Overlooking to anchor changes securely in the company culture.

5. Pursue Perfection

Leaders are there to implement lean and pursuing perfection makes Lean thinking and continuous process improvement a part of the organizational culture for leaders. Every leader should make their employee to strive towards perfection while delivering products. The company should be a learning organization and always find ways to get a little better every new day.

Handpicked for our Leaders: What exactly is Digital Transformation in 21st Century?

Sometimes this can be a barrier in implementing improvements too. As in dream of perfection we forget to be better. It is far better to take baby steps in the road to perfection than it is to wait until you think you can get perfection in one huge jump. Don’t let perfection be the enemy of being better.

Conclusion

Here are some lean deployment points that leader should keep in mind for business excellence, customer excellence, manufacturing and operational excellence to produce best cost efficient products by implementing some habits in our routine, understanding the value, mapping the value stream, make no mistake while implementation and pursue perfection.

Read More: https://learntransformation.com/5-habits-of-lean-management/