3D Printing in Computer-Aided Surgery Research

Aman AgarwalIn my last post, I talked about different types of rapid prototyping technologies. In this post, I’ll go over different applications of 3D printing for computer-aided surgery research.

This topic came up by reader request. If there is anything you would like me to cover, just let me know. If there is something that you would like to talk about, I encourage guest bloggers!

Let’s get to it.

Also read: origin overlay disabled titanfall 2

Powerful use of 3D printing technology is the ability to make customizable parts for experimental apparatus. I’ve used 3D printing to create models for mold making.

The advantage is that you can use a patient image from MR or CT and use CAD software to adjust the model to your needs.

In this picture, rapid prototyping was used to create the vertebra model and mounts for the passive rigid bodies (the glowing spheres) for the optical tracking system (out of view).

Apparatus for a pedicle screw laboratory study. Rapid prototyping was used to in the manufacture of the vertebra models.

Patient Models

A model of the patient’s anatomy is simply printed out so that the surgeon can examine the procedure from the inside out. Cardiac procedures and pedicle screw placements are just two surgeries that have benefited from the technology.

My surgical colleagues say that they really like having the physical model in their hand for assessment. 3Dventures is a company that prints these patient-specific models from DICOM data.

Customizable Surgical Guides

I’ve talked about customizable surgical guides before. The idea is to customize surgical jigs based on patient anatomy.

For example, this is a picture of a custom drill guide (far left) mounted on a distal radius for attaching a fixation plate (far right) during distal radius osteotomy (thank you to Professor Burton Ma for use of the image).

A customizable surgical for distal radius osteotomy. The prototyped guide is used to position drill.

Klaus Radermacher is a pioneer in the field of patient-specific guides for orthopaedic procedures. Surgical procedures that use these devices include: pedicle screw placement, hip resurfacing, and total knee arthroplasty, to name a few. I will be attending a workshop at Computer-Assisted Orthopaedic Surgery in mid-June.

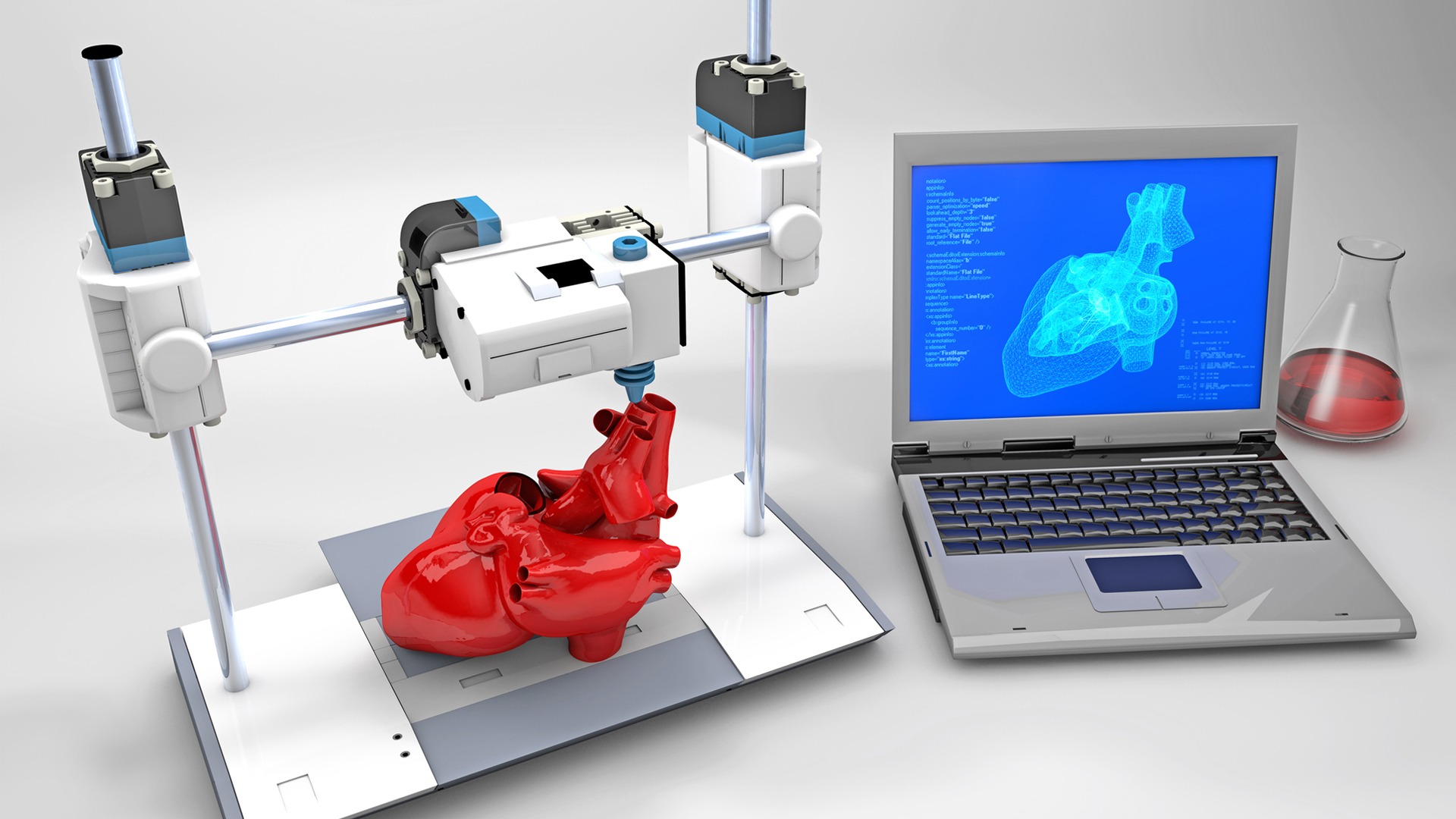

Printing Implants, Tissue, and Organs

In orthopedics, models fabricated with 3D printers are used as external guides but not as implants because of the mechanical properties of the printable materials.

Techniques like electron beam melting or laser sintering where models can be constructed from titanium or cobalt chrome, make implantable models possible. In fact, Stryker Orthopaedics acquired OtisMed, a company that specializes in customizable implants, in late 2009.

We’ve talked a lot about bone, but what about soft tissue and organs? Invetech and Organovo are two companies working on bringing 3D bioprinting to market.

The principles are the same as 3D printing; layers of a material (in this case, humans cells) are laid and held into place by scaffolding (support material), when the object is complete, the scaffold is washed away. For further reading, Organovo provides a list of peer-reviewed publications on the topic.

Other Applications of 3D Printing

Additional applications of 3D printing include a personal food factory being developed at MIT. It looks to be pretty early in development and it is not exactly clear to me how the food properties are controlled (temperature, etc), but it’s an interesting insight into what our future dinners may look like.

Another interesting 3D printing application is programmed-release multi-drug implants for bone tuberculosis therapy.

Read More: how to enable origin overlay in titanfall 2