Wikipedia

en.m.wikipedia.org

HistoryEdit

StructureEdit

Main article: Aromaticity

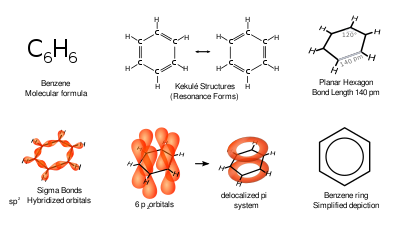

The various representations of benzene

X-ray diffraction shows that all six carbon-carbon bonds in benzene are of the same length, at 140 picometres (pm). The C–C bond lengths are greater than a double bond (135 pm) but shorter than a single bond (147 pm). This intermediate distance is consistent with electron delocalization: the electrons for C–C bonding are distributed equally between each of the six carbon atoms. Benzene has 6 hydrogen atoms – fewer than the corresponding parent alkane, hexane. The molecule is planar.[44] The MO description involves the formation of three delocalized π orbitals spanning all six carbon atoms, while the VB description involves a superposition of resonance structures.[45][46][47][48] It is likely that this stability contributes to the peculiar molecular and chemical properties known as aromaticity. To accurately reflect the nature of the bonding, benzene is often depicted with a circle inside a hexagonal arrangement of carbon atoms.

Derivatives of benzene occur sufficiently often as a component of organic molecules that the Unicode Consortium has allocated a symbol in the Miscellaneous Technical block with the code U+232C (⌬) to represent it with three double bonds,[49] and U+23E3 (⏣) for a delocalized version.[50]

Benzene derivativesEdit

Main articles: Aromatic hydrocarbons and Alkylbenzenes

Many important chemical compounds are derived from benzene by replacing one or more of its hydrogen atoms with another functional group. Examples of simple benzene derivatives are phenol, toluene, and aniline, abbreviated PhOH, PhMe, and PhNH2, respectively. Linking benzene rings gives biphenyl, C6H5–C6H5. Further loss of hydrogen gives "fused" aromatic hydrocarbons, such as naphthalene and anthracene. The limit of the fusion process is the hydrogen-free allotrope of carbon, graphite.

In heterocycles, carbon atoms in the benzene ring are replaced with other elements. The most important variations contain nitrogen. Replacing one CH with N gives the compound pyridine, C5H5N. Although benzene and pyridine are structurally related, benzene cannot be converted into pyridine. Replacement of a second CH bond with N gives, depending on the location of the second N, pyridazine, pyrimidine, and pyrazine.[51]

ProductionEdit

Four chemical processes contribute to industrial benzene production: catalytic reforming, toluene hydrodealkylation, toluene disproportionation, and steam cracking. According to the ATSDR Toxicological Profile for benzene, between 1978 and 1981, catalytic reformats accounted for approximately 44–50% of the total U.S benzene production.[43]

Catalytic reformingEdit

In catalytic reforming, a mixture of hydrocarbons with boiling points between 60–200 °C is blended with hydrogen gas and then exposed to a bifunctional platinum chloride or rhenium chloride catalyst at 500–525 °C and pressures ranging from 8–50 atm. Under these conditions, aliphatic hydrocarbons form rings and lose hydrogen to become aromatic hydrocarbons. The aromatic products of the reaction are then separated from the reaction mixture (or reformate) by extraction with any one of a number of solvents, including diethylene glycol or sulfolane, and benzene is then separated from the other aromatics by distillation. The extraction step of aromatics from the reformate is designed to produce aromatics with lowest non-aromatic components. Recovery of the aromatics, commonly referred to as BTX (benzene, toluene and xylene isomers), involves such extraction and distillation steps. There are a good many licensed processes available for extraction of the aromatics.

In similar fashion to this catalytic reforming, UOP and BP commercialized a method from LPG (mainly propane and butane) to aromatics.

Toluene hydrodealkylationEdit

Toluene hydrodealkylation converts toluene to benzene. In this hydrogen-intensive process, toluene is mixed with hydrogen, then passed over a chromium, molybdenum, or platinum oxide catalyst at 500–600 °C and 40–60 atm pressure. Sometimes, higher temperatures are used instead of a catalyst (at the similar reaction condition). Under these conditions, toluene undergoes dealkylation to benzene and methane:

C6H5CH3 + H2 → C6H6 + CH4

This irreversible reaction is accompanied by an equilibrium side reaction that produces biphenyl (aka diphenyl) at higher temperature:

2 C

6H

6 ⇌ H

2 + C

6H

5–C

6H

5

If the raw material stream contains much non-aromatic components (paraffins or naphthenes), those are likely decomposed to lower hydrocarbons such as methane, which increases the consumption of hydrogen.

A typical reaction yield exceeds 95%. Sometimes, xylenes and heavier aromatics are used in place of toluene, with similar efficiency.

This is often called "on-purpose" methodology to produce benzene, compared to conventional BTX (benzene-toluene-xylene) extraction processes.

Toluene disproportionationEdit

Where a chemical complex has similar demands for both benzene and xylene, then toluene disproportionation (TDP) may be an attractive alternative to the toluene hydrodealkylation. In the broad sense, 2 toluene molecules are reacted and the methyl groups rearranged from one toluene molecule to the other, yielding one benzene molecule and one xylene molecule.

Given that demand for para-xylene (p-xylene) substantially exceeds demand for other xylene isomers, a refinement of the TDP process called Selective TDP (STDP) may be used. In this process, the xylene stream exiting the TDP unit is approximately 90% paraxylene. In some current catalytic systems, even the benzene-to-xylenes ratio is decreased (more xylenes) when the demand of xylenes is higher.

Steam crackingEdit

Steam cracking is the process for producing ethylene and other alkenes from aliphatic hydrocarbons. Depending on the feedstock used to produce the olefins, steam cracking can produce a benzene-rich liquid by-product called pyrolysis gasoline. Pyrolysis gasoline can be blended with other hydrocarbons as a gasoline additive, or routed through an extraction process to recover BTX aromatics (benzene, toluene and xylenes).

Other methodsEdit

Although of no commercial significance, many other routes to benzene exist. Phenol and halobenzenes can be reduced with metals, for example. Benzoic acid and its salts undergo decarboxylation to benzene. Via the reaction the diazonium compound with hypophosphorus acid aniline gives benzene. Trimerization of acetylene gives benzene.

UsesEdit

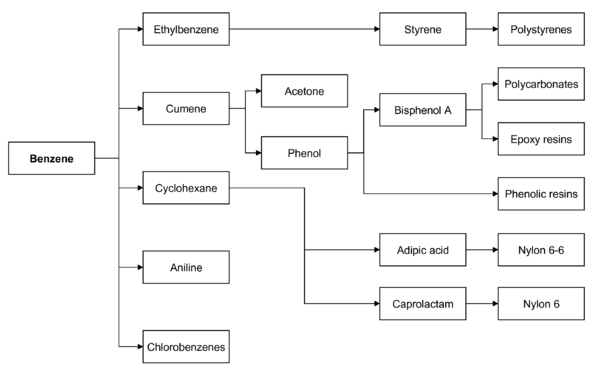

Benzene is used mainly as an intermediate to make other chemicals, above all ethylbenzene, cumene, cyclohexane, nitrobenzene, and alkylbenzene. More than half of the entire benzene production is processed into ethylbenzene, a precursor to styrene, which is used to make polymers and plastics like polystyrene and EPS. Some 20% of the benzene production is used to manufacture cumene, which is needed to produce phenol and acetone for resins and adhesives. Cyclohexane consumes ca. 10% of the world's benzene production; it is primarily used in the manufacture of nylon fibers, which are processed into textiles and engineering plastics. Smaller amounts of benzene are used to make some types of rubbers, lubricants, dyes, detergents, drugs, explosives, and pesticides. In 2013, the biggest consumer country of benzene was China, followed by the USA. Benzene production is currently expanding in the Middle East and in Africa, whereas production capacities in Western Europe and North America are stagnating.[52]

Toluene is now often used as a substitute for benzene, for instance as a fuel additive. The solvent-properties of the two are similar, but toluene is less toxic and has a wider liquid range. Toluene is also processed into benzene.[53]

Major commodity chemicals and polymers derived from benzene. Clicking on the image loads the appropriate article

Component of gasolineEdit

As a gasoline (petrol) additive, benzene increases the octane rating and reduces knocking. As a consequence, gasoline often contained several percent benzene before the 1950s, when tetraethyl lead replaced it as the most widely used antiknock additive. With the global phaseout of leaded gasoline, benzene has made a comeback as a gasoline additive in some nations. In the United States, concern over its negative health effects and the possibility of benzene's entering the groundwater have led to stringent regulation of gasoline's benzene content, with limits typically around 1%.[54] European petrol specifications now contain the same 1% limit on benzene content. The United States Environmental Protection Agency introduced new regulations in 2011 that lowered the benzene content in gasoline to 0.62%.[55]

ReactionsEdit

Health effectsEdit

Exposure to benzeneEdit

See alsoEdit

ReferencesEdit

Edit

Source en.m.wikipedia.org