What do you know about laminated fabrics from SG-ARMY?

PU and PTFE fabric lamination and breathable membraneSynergy Goldtech LTD, SOFIA, BULGARIA

B2B blog SG-ARMY

The factories that we represent, disposes of a complete technological lines and machinery - preparation, weaving, fabric finishing for the production of all kind woven and non-woven fabrics.

In this brief review, we will show you the most technologically advanced materials that can be ordered from SG-ARMY - membranes. These wonderful material for a long time serve the people, and are used in various fields of human activity. From urban clothing, and to complex textiles for extreme use, which have saved many lives.

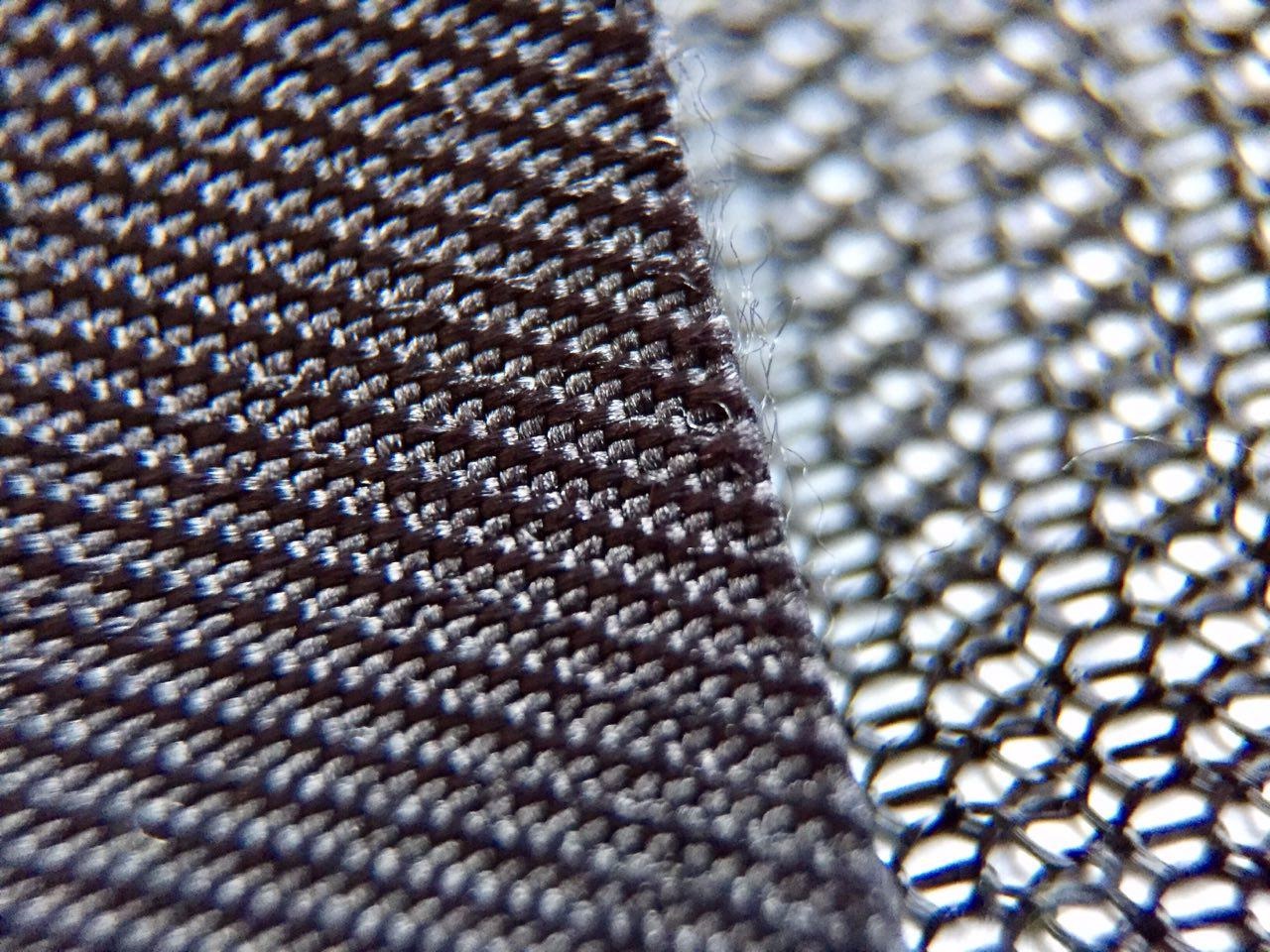

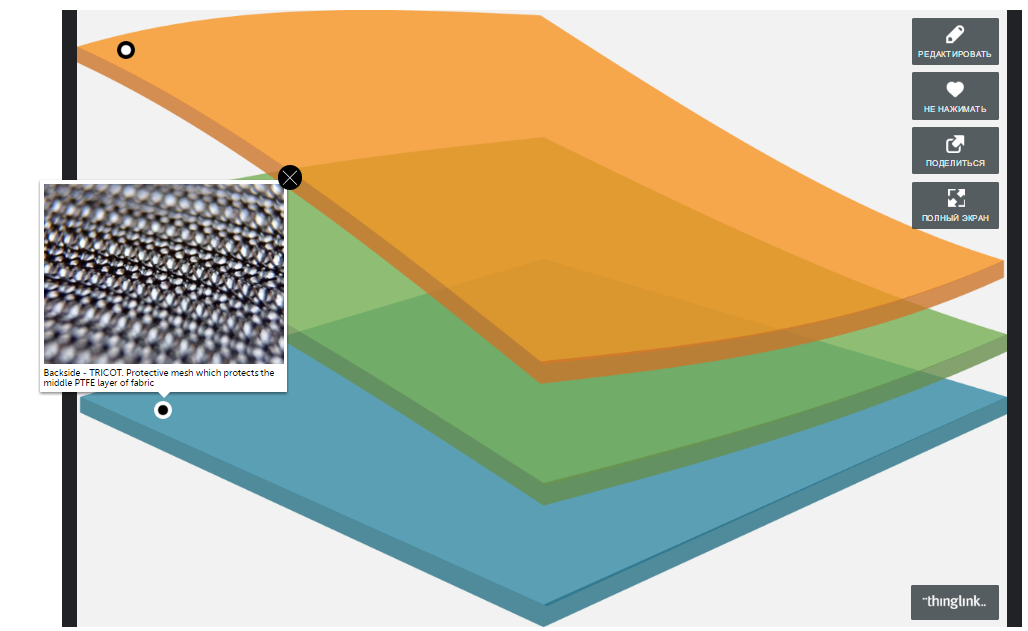

What is the 3-Layer membrane in our products line?

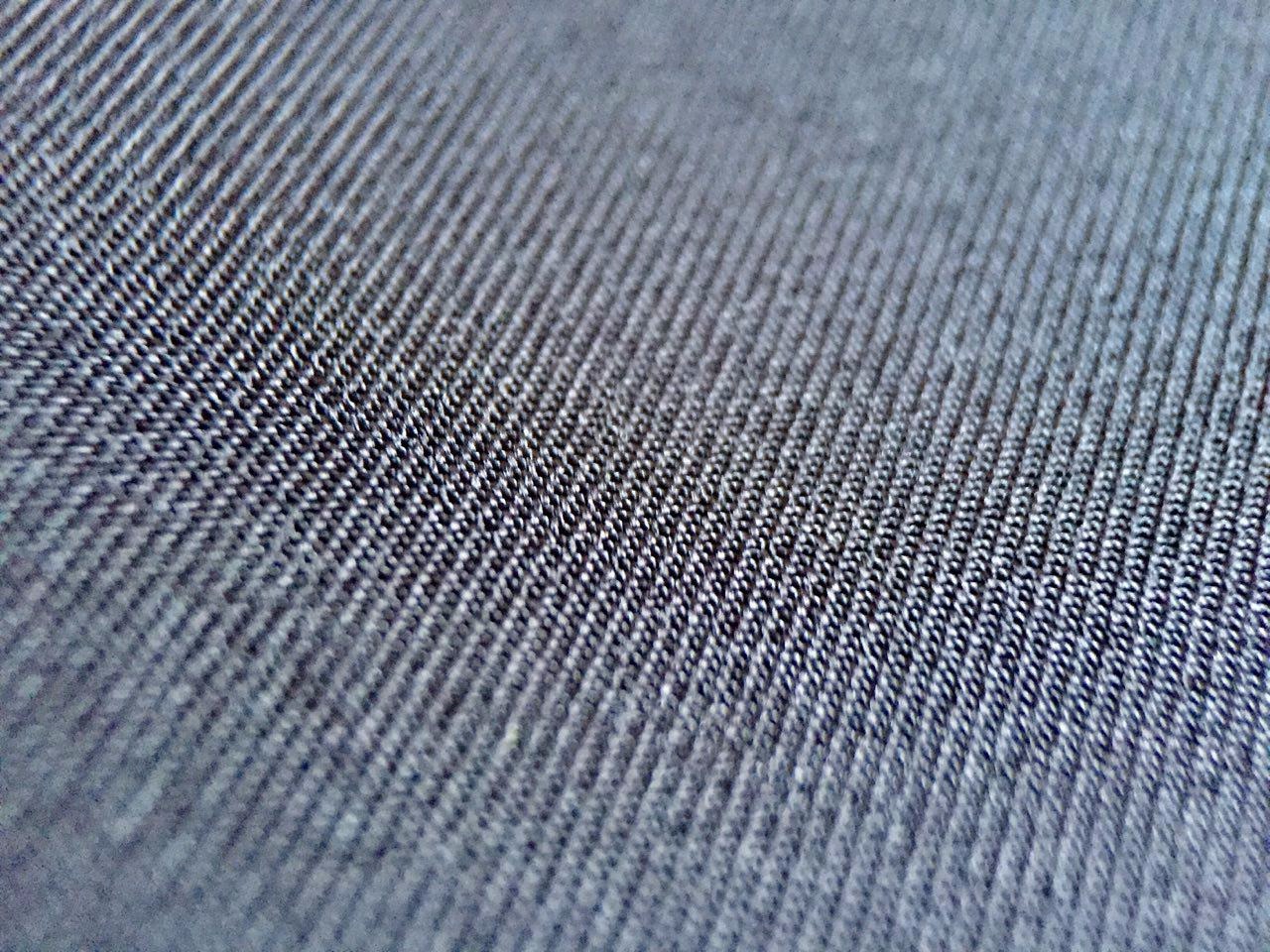

The first layer - the outer, polyamide, polyester and mixed fabric based on cotton, with any weave density of up to 350 grams, and any color or print.

https://www.thinglink.com/scene/870236297917104132

Other types of membranes: 2 layer PTFE fabrics.

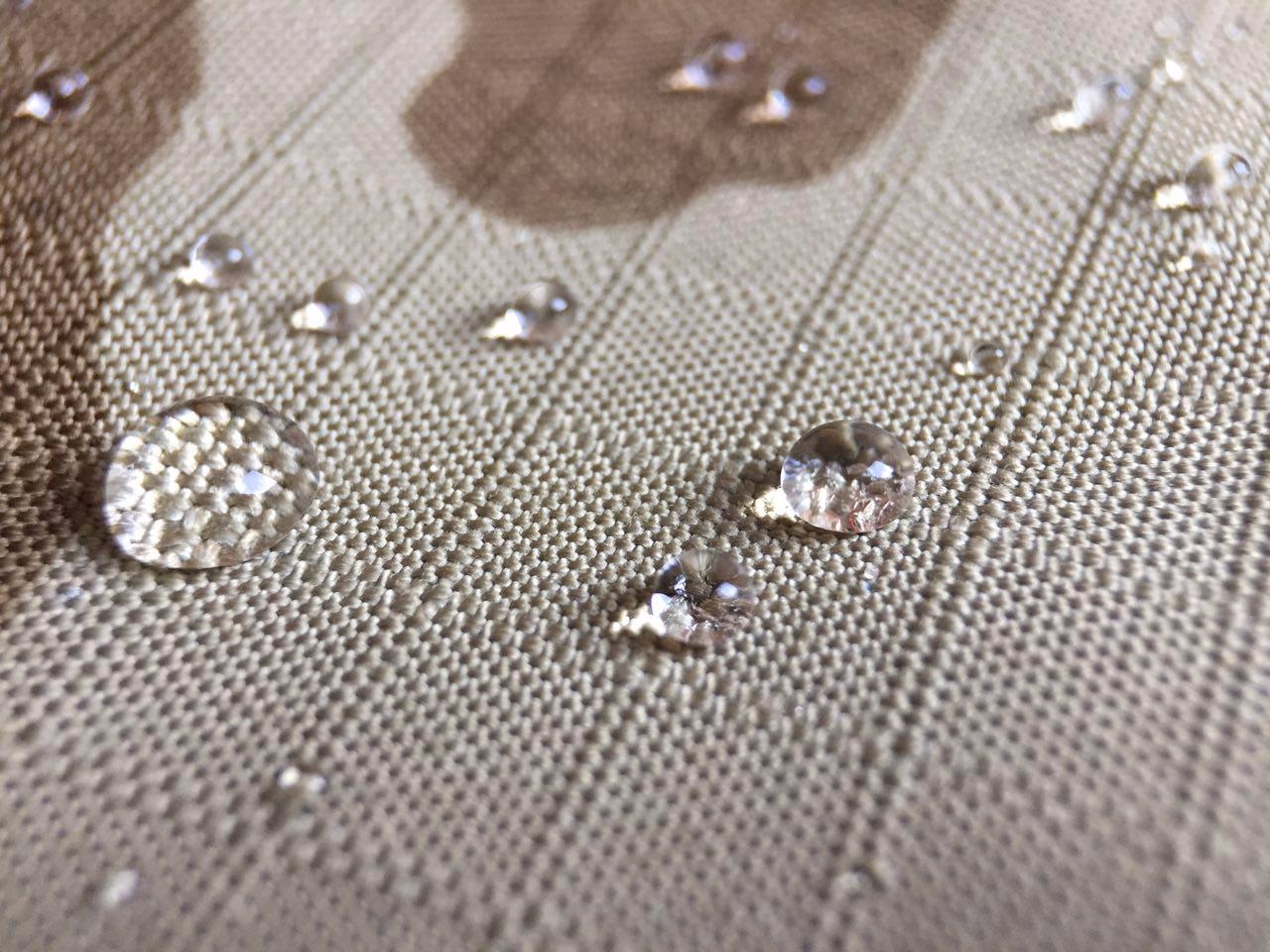

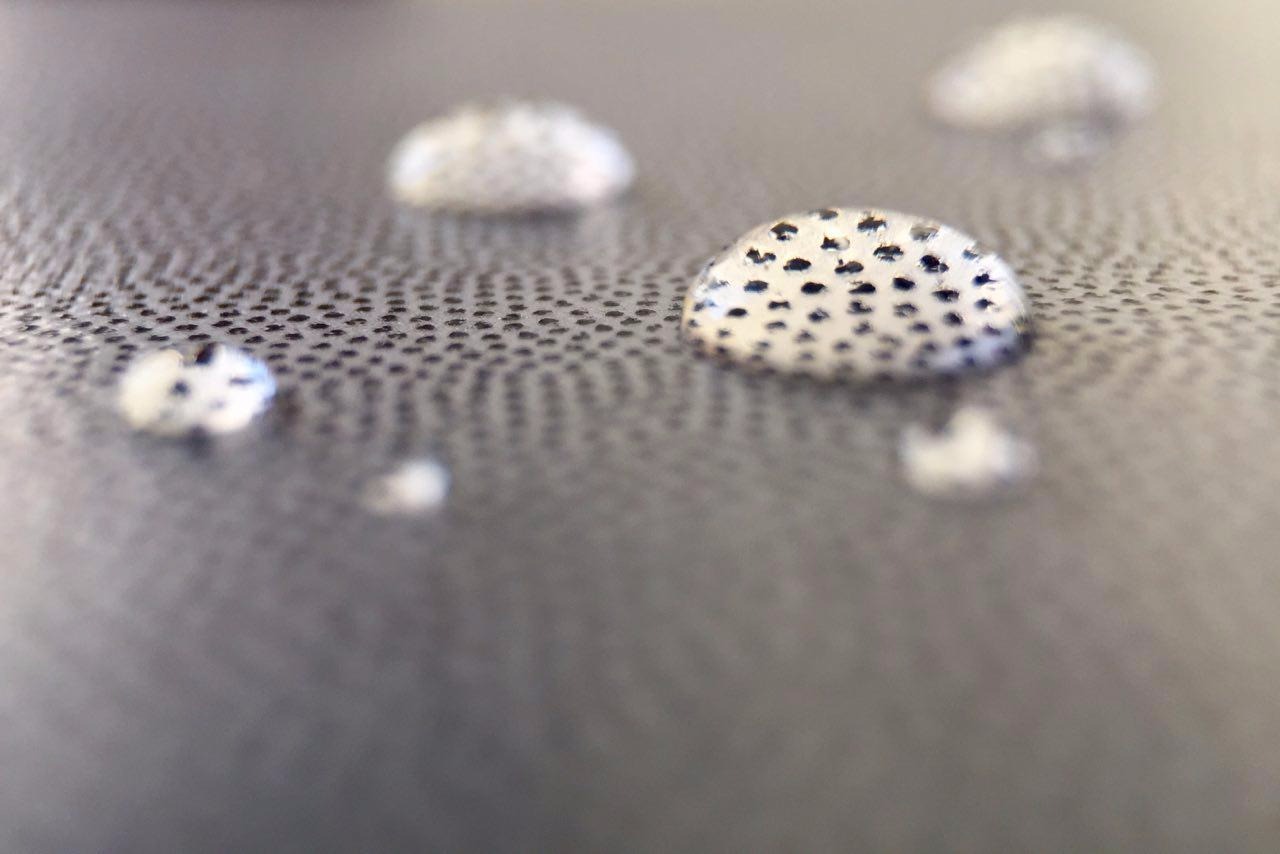

They consist of an outer layer of tissue, and membrane layer type PTFE. As for outer layer. Wide range of fabric finishing - water & oil repellent, flame-retardant, anti-bacterial protection, insect-repellent

OUTER LAYER: cotton and cotton type fabrics in differnet blends with polyester, polyamide, 100% polyamide or polyester fabrics in wide range of weights starting from 70 g/m2 to 350 g/m2 in differnet weavings (twill, rip-stop, satin), finishing of above-mentioned fabrics as a unicolor or printed.

ISO 9001:2000, ISO 14001: 1996, ACAP 2110 and all of the products are satisfying OEKO-TEX® Standard 100.

Other types of breathable membranes: PU laminated

Thin, durable and productive membrane

Polyamide rip-stop PU membrane, 100 gr/m2. Hydrostatic head 5000 mm by EN 20811, water vapour resistance Ret <20 m2*Pa/W

WELCOME TO SG-ARMY COMMUNITY!

Contact us: office@sg-army, +359-88843-8883, Bulgaria, sg-army.com