Deep Hole Drilling Machines

👉🏻👉🏻👉🏻 ALL INFORMATION CLICK HERE 👈🏻👈🏻👈🏻

This 5-Axis multifunctional machine is a column moving type gun drilling M/C. Machine’s work table can be classified into a fixed type, a rotary type and a type that can be transferred to front and back.

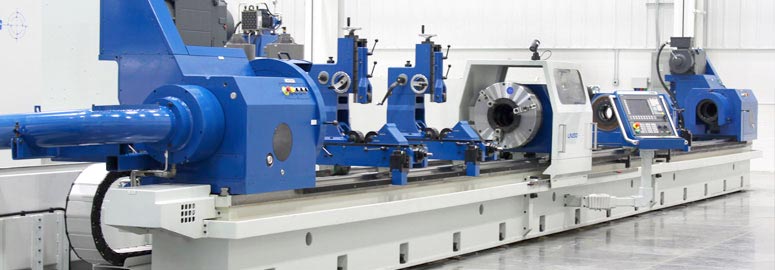

This BTA drilling machine is a column moving type deep-hole drilling machine equipped with the gun-drilling function with a small diameter and the BTA-drilling function with a large diameter or a combination.

Our drill center is 2-spindle gantry type drill center. While each spindle head is individually transferred, it is possible to execute duties at the same time.

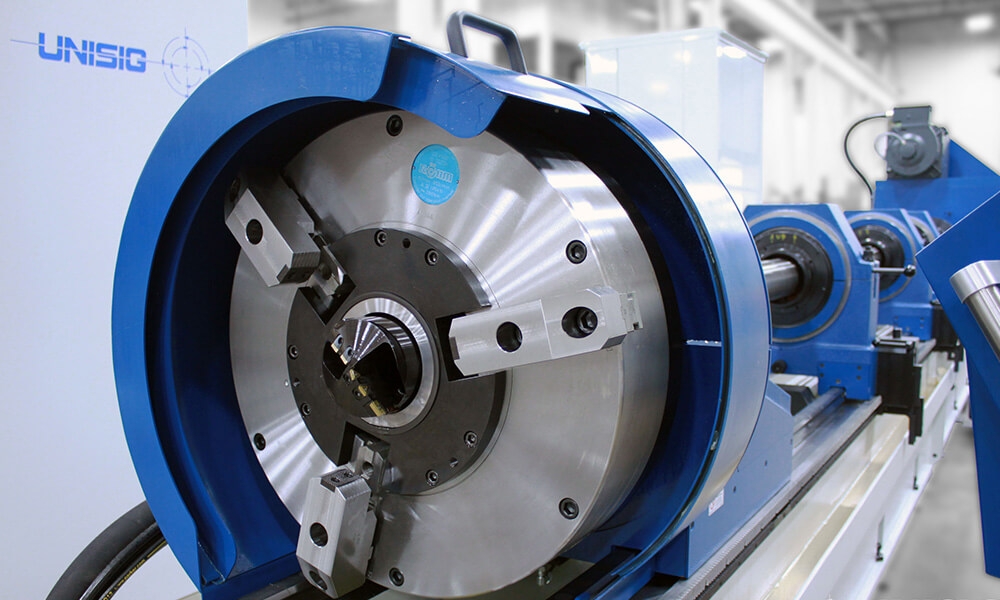

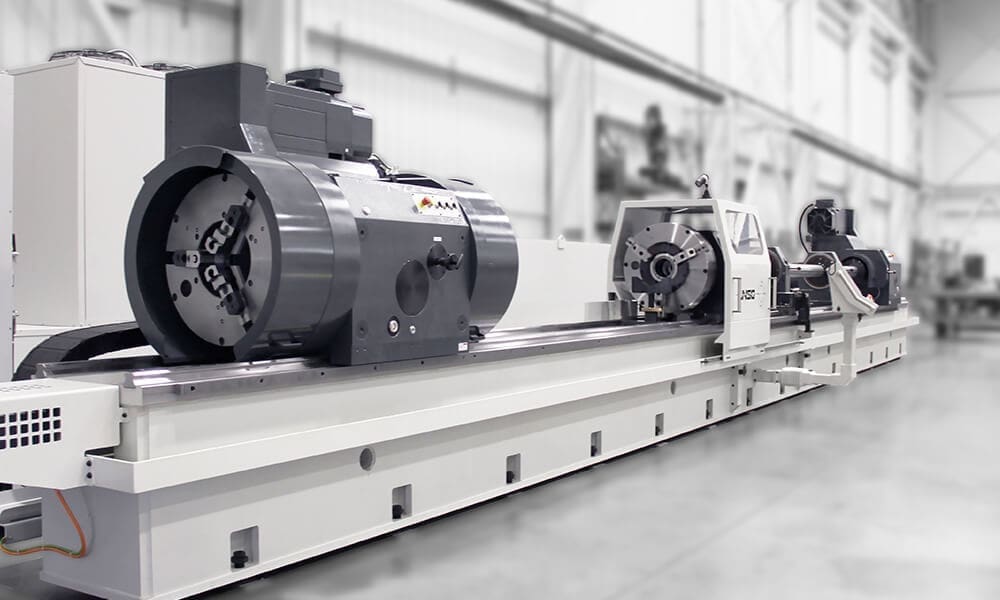

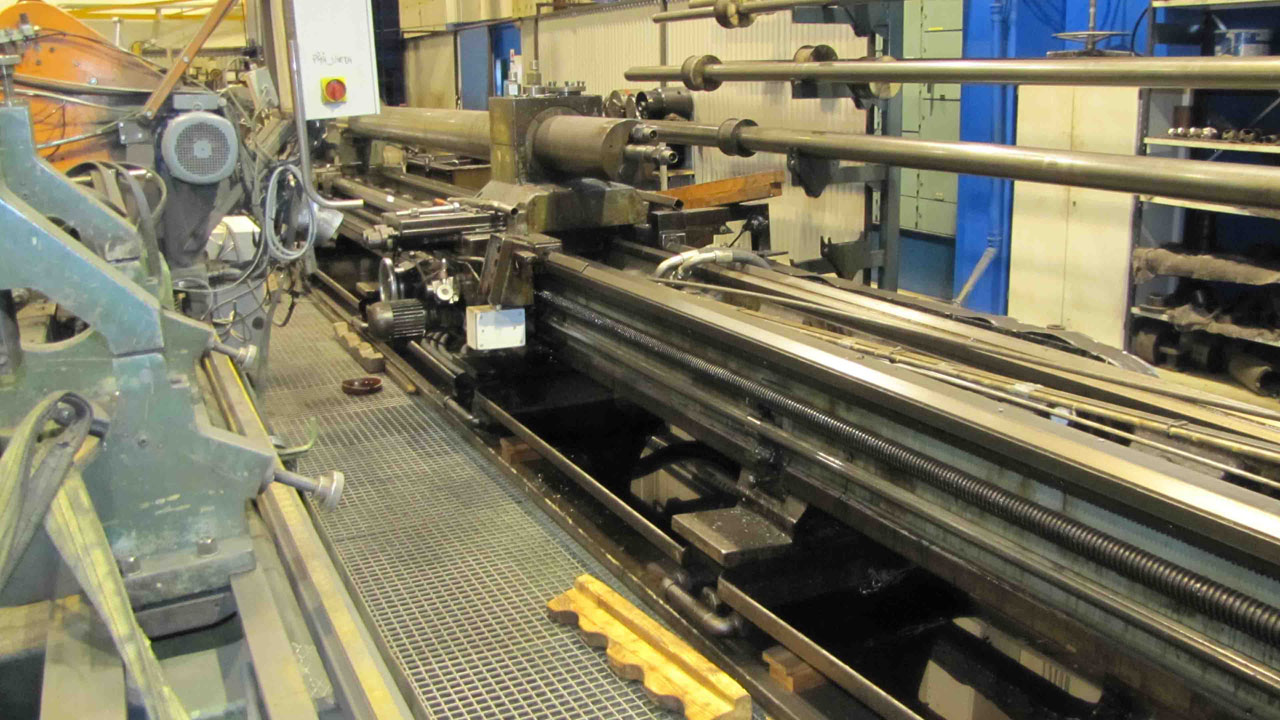

Lathe type BTA drilling machine is a BTA drilling machine mainly used for shafts. It can be classified into a fixed tool with rotating workpiece and a rotating tool with rotating workpiece.

Our multi-axis gun drill machine is an exclusive 2-4 spindle equipment used for the processing of automobile steering rack bars, other automobile components and air craft parts.

Our special purpose gun drill machine is used to engrave notches on the steel roller.

Single Flut Gun Drilling Tools (Brazed Type) can be seen as the advanced and high-efficient deep hole process technology.

Twin Fluted Gun Drills Tools can be seen as the advanced and high-efficient deep hole process technology.

Shin-il BTA System Drilling Process can be seen as the advanced and high-efficient deep hole process technology.

From the shank to the tip, solid carbide CNC gun drills have full carbide construction, better for cooling liquid flowing.

Shin-il Machinery Co., Ltd. was established in 1971 and is a specialized manufacturer of special CNC machines with a history of nearly 50 years.

The main products are CNC gun drilling machine (1 spindle, 2 spindles, multi-axis gun drill), BTA tube sheet drilling machine, high-speed drill center, a portable boring machine which supplied in fields of aerospace, medical, automobile, mold, petrochemical, nuclear power, wind power, heavy industry, construction industry, etc. We have successfully provided thousands of units for our customers.

We show our true hearts to serve every clients.

The problem of chip removal in gun-drilling deep hole drilling is still a technical problem. If the chips cannot discharge

Gun drill deep hole processing has a long history. With the development of machinery manufacturing technology, the gun drill has

In the process of deep hole drilling, to improve the cutting efficiency, improve the accuracy of the workpiece, reduce the

Processing characteristics of deep hole drilling The tool holder is limited by the aperture, small diameter, and considerable length, resulting

The deep hole drill is a drill bit specially designed for machining deep holes, which can be divided into two types: outer chip removal and inner chip removal.

The biggest drawback of deep drilling is the difficulty of heat dissipation and chip evacuation.

The drill is specifically designed to machine deep holes.

When a hole depth ratio greater than 6 is usually referred to as a deep hole in machining.

In deep hole drilling, heat dissipation and chip removal are difficult, and the drill pipe is slender and has poor rigidity, which is prone to bending and vibration.

Cooling and chip removal problems are generally addressed by means of a pressure cooling system

Deep hole processing characteristics

Shank of drill machine has a slender and rigid rigidity, and it is difficult to discharge the chips.

Due to the tool cutting ability in the hole, cutting conditions and tool wear cannot be observed.

Drilling deep hole method

Diameter 3 ~ 20mm with a gun hole drill.

Diameter 20 ~ 65mm with high-pressure internal chip removal deep hole drilling or with the suction drill, can also be used with indexable insert staggered deep hole drilling

Deep hole drill is divided into two types: outer chip removal and inner chip removal according to chip removal method.

There are gun drills, electric flute drills,s and deep hole twist drills for external chip removal; the internal chip removal is divided into three types: BTA deep hole drill, jet drill, and DF deep hole drill.

By using CNC spindles gun drills are usually with high-speed steel or hard alloy features.

Various types of internal chip removal deep hole drills can be constructed according to the size of welded or mechanically clamped indexable carbide inserts.

The guide block on the deep hole drill and centers to reduce deflection of borehole and vibration during cutting.

The arrangement of the teeth and guide blocks of deep hole drill mainly considers radial force balance during chipping and cutting.

The body and the drill pipe can be joined by welding or square threads.

No products were found matching your selection.

Drilling Machine: The process of machining a hole in a solid material with a drill bit is called drilling, and the special device for drilling is called a drilling machine.

Deep hole drilling machine: Deep hole drilling machine is one of the working parts of the tool that is mostly surrounded by the machined surface.

Therefore, there are problems such as rigidity, chip removal, guiding, and cooling lubrication of the tool.

The bit of deep hole drilling machine has poor rigidity and is easy to “bias” when drilling.

Limitation by the machining hole is the reason, which is generally long, and at the same time, it is required to have the largest possible chip on the drill bit.

The groove facilitates chip evacuation, which makes the core thinner and thus less rigid.

Due to the rigidity and guiding of the drill bit (drilling, only two narrow edges of the drill bit are in contact with the hole wall), the two main cutting edges are difficult to be symmetrical, and the radial forces cannot cancel each other out.

Moreover, the first contact with the machined surface during drilling is the chisel edge with a large negative rake angle, which makes it difficult for it to enter the cutting.

Therefore, the carbide drill bit is prone to “biasing” when drilling, resulting in the axis of a drilled hole. Skew or aperture expansion, not round, etc.

When drilling a deep hole with a special deep hole drill, the tool will exit quickly after a certain period of feed, the workpiece will be chipped, and then quickly approach machining part and continue to feed, so many times to reciprocate until required hole depth is processed.

Common problems and solutions

Rough surface

Chip bonding: reduce the cutting speed; avoid chipping; replace cutting fluid with high pressure and improve the filtration; increase pressure and flow of the cutting fluid.

Poor coaxial: adjust the coaxiality of machine tool spindle and drill sleeve; use appropriate drill sleeve diameter.

The cutting speed is too low, the feed rate is too large or uneven: use the appropriate cutting amount.

Tool geometry is not suitable: change the geometry of cutting edge and the shape of a guide block

The orifice is flared

Poor coaxial: adjust the coaxiality of machine tool spindle, drill sleeve and support sleeve; use the appropriate diameter of drill sleeve to replace oversized drill sleeve in time.

Bit break

The chip breaking is not good, the chips can not be discharged: change the size of chip breaking groove to avoid too long and too shallow; find the chipping situation in time and replace it; increase the pressure and flow of cutting fluid; use workpiece with the uniform material organization.

The feed is too large, too small, or uneven: use the appropriate amount of cutting.

Excessive wear of the drill bit: Regularly replace the drill bit to avoid excessive wear.

The cutting fluid is not suitable: select the appropriate cutting fluid and improve the filtration.

Low bit of life

The cutting speed is too high or too low, and the feed rate is too large: use the appropriate cutting amount.

Inappropriate bit: Replace tool material; change the position and shape of the guide block.

The cutting fluid is not suitable: use the cutting fluid with high extreme pressure; increase the pressure, flow, and filtration of the cutting fluid.

Other

Chips in strip shape: chipbreaker geometry is not suitable; cutting edge geometry is not suitable; feed amount is too small; workpiece material organization is uneven: variable chipbreaker and cutting edge geometry; increase feed rate; A material that is evenly organized.

The chip is too small: the chipbreaker is too short or too deep; the chipbreaker radius is too small: the geometry of the chipbreaker is varied.

Excessive chip: the chipbreaker is too long or too shallow; the chipbreaker radius is too large: the geometry of the variable chipbreaker

Tel: +82 51 315 1818

Fax: +82 51 311 1819

Add: 59, Nakdong-daero 916 beon-gil, Sasang-gu. Republic of Korea

Shin-il Stark Machinery (Suzhou) Co., Ltd

Tel: +86 512 6290 1818

Fax: +86 512 6290 1819

Add: No.2018-E2, Haizang Road, Luzhi Town, Wuzhong District, Suzhou City, Jiangsu Province, 215127, China

Copyright © 2019 Shin-il Stark Machinery (Suzhou) Co., Ltd

Profimach® Deep Holes drilling Machines

High quality affordable deep hole machines

BTA Drilling Machines

Affordable and good

Profimach® - Built for Europe

High Quality Affordable Metal Working Machines for Hole processing

Gun Drilling Machines

The biggest and most affordable range available on the market

SRB Machines - Skiving Roller Burnishing Machines

High quality but affordable

Our Deep hole machines - Our Deep hole cutting solutions

Gundrilling machines - Deep hole drilling machines - BTA drilling machines - BTA boring Machines - SRB Machines - High speed deep hole drilling machines - Micro drilling machine - Mold drilling machine - Table type drilling machine

Our deep hole working machines are offered

with a full two-year limited warranty.

What deep hole machining do you have in mind?

Deep Hole Machining Processes our machines can do:

Gun drilling process is used to produce deep and straight holes. This process is very specialised as compared to the conventional twist drilling process. The standard gun drill tool geometry has a single effective cutting edge. Unlike the twist drill the gun drill cuts through the metal eccentrically and once inside the component the tool self-pilots itself. The hole is further burnished due to the guide pads which finally results in a precise round hole with maintained straightness. The Coolant enters the tool through the coolant through hole and the chips are gushed out through the V shaped profile on the gun drill. Gun Drilling is effective from ф1 to ф30, but if you wish to go higher, BTA drilling becomes more effective than gun drilling.

Gundrilling, one of the basic and frequently performed material removal processes in the automotive, die and mold, and turbine industries, is becoming increasingly more complex, demanding, and experiences an unprecedented growth. Inspite of significant increase in the demand for economically producing holes and forprocess reliability, gundrilling and gundrill manufacture are still considered an esotericart, and there still exists a lackof knowledge on the exact relationships between the point geometry, the grinding process parameters, and the process mechanics, resulting inmany methods for drill production and, consequently, in wide variations in process performance.

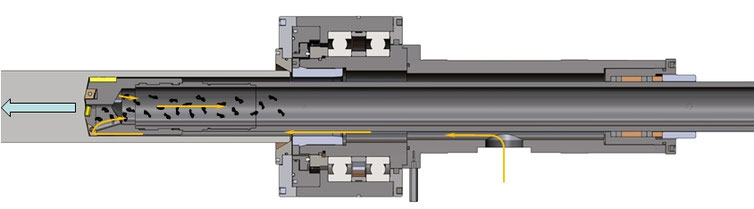

BTA stands for Boring and Trepanning Association which developed this deep hole drilling system. It involves a single drill tube in which high pressure coolant is supplied to the drill through the annular area between the drilled hole and the tube outer diameter. The chips are evacuated through the I.D. of the tube. The drill head is screwed to this drill tube which is much stronger compared to the kidney shaped shank of a gun drill, hence much higher metal removal rates are possible. This involves the use of a Pressure head which is basically a high pressure seal between the workpiece and the drill bush. BTA/STS drilling is generally used for ф19 and above.

Since the chip removal is internal, no v shaped groove is required in the shank, so its cross-section is completely round and this provides more rigidity to the entire system. BTA drilling finds its application in Industries like Oil & Gas, Defence, Steel, Aircraft, Aerospace, Hydraulic Cylinders, and Power etc. For larger diameter deep hole drilling, BTA drilling is the only available option which provides high productivity and precision.

Another system which evolved from BTA single tube system is the Ejector drilling system. It is a system with twin tubes where the coolant is pumped through the space between the inner and outer tube. This eliminates the use of Pressure head and simplifies the system. This was introduced mainly to tool up conventional machines to do Deep hole Drilling.

Trepanning is a special operation mainly used on when conventional machines are tooled up to do deep hole drilling. Usually in such cases the machine power is less and hence Solid BTA drilling is not possible. Trepanning is also used when a solid core is required. The trepanning operation is performed on a blank workpiece without any holes. The Tool geometry allows cutting only on the circular section whereas a solid core is left in the middle. This core can later be extracted for use. Typically only through hole applications are advisable with Trepanning since the core extraction can become troublesome in case of a blind hole. The tool covers a large range of diameters upto 500mm. There are limitations to the lower level of diameter that can be achieved with this process due to the geometry of the tool.

Ejector Drilling is similar to BTA Drilling operation with the difference that it has Twin tubes instead of a single tube.The high pressure Coolant is pumped to the cutting face through the annular area between the outer tube and the inner tube. There is a special connector for holding both the tubes and also to feed the high pressure coolant.The pressure head with rear coolant sealing that is required in BTA drilling is eliminated here and only a guide bush is needed.The Chips generated are evacuated through the inner tube where ejection effect is generated at the rear end to help in chip evacuation.The area for chip discharge is comparatively less than BTA and hence the evacuation is not as efficient particularly in smaller sizes. Since the tube diameter is larger than BTA Drilling the torsional strength also goes up. This can be an advantage to go for higher feeds. This is usually used to retrofit conventional machines for deep hole drilling.

Skiving is a hole finishing process used when very tight dimensional and geometrical tolerances are required. It is the fastest method to achieve surface finish having very fine peaks and valleys ideal for roller burnishing process. The Skiving Tool is basically a twin/multiple edge floating reamer which follows the existing bore. The Roller burnishing tool coldworks the surface by merging peaks & valleys thereby producing very high surface finish and also a hardened surface. Both Skiving and Roller burnishing processes can be done simultaneously by using combined Skiving cum Roller Burnishing Tool. This process is 8 – 10 times faster than honing operation. The Skiving blades and burnishing rollers are expanded hydraulically while rotating and feeding though the bore. At the end of the operation these are retracted and the tool is withdrawn. High pressure coolant is supplied to the tool through the annular area between the bore and the tube outer diameter. The coolant along with the chips is evacuated from the other side.

Profimach offers dedicated Skiving & Burnishing machines for high production scenarios. This setup can be accommodated in a BTA drilling machine.

Honing is a process that uses Silicon Carbide , Aluminum Oxide, CBN or Diamond tools to polish the ID of a cylindrical shaft . These tools are mounted on a mandrel that is rotated and reciprocated at the same time. Expansion of the mandrel is controlled by servo controls or hydraulically. Honing gives a surface finish of 0.1 Ra or better in most cases.

Counter Boring operation basically enlarges a pre-drilled bore. Usually counter boring is used when machine power does not allow solid drilling of that size.It covers a large range of diameters up to 500mm. The number of cutting edges on the tool can vary depending upon the amount of stock removal. As the counter bore tool enters the component, the pads are supported by the finished bore diameter. The Coolant and chips flow is similar to BTA drilling operation or chip forward.

Gun Drilling and BTA drilling operations usually leave the bottom of the hole with a “W” Shaped profile. Bottom forming is a process that is basically used to generate a flat bottom or a profiled end for a pre-drilled hole. It’s an operation to finish the end of the hole. The desired end can be generated for example Flat bottom, steps, radius etc.

Pull boring is being used mainly to have very straight and accurate long holes. The oil is fed similar to BTA drilling or counter boring i.e. through the pressure head. This has guide pads which are supported in the pre-bore, thus producing the enlarged bore on the original axis.

Bottle boring is mainly used for generating internal profiles in pre-drilled bores.The Tool design allows for the expansion or retraction of the cutter when actuated from rear end. This can be used to produce the required internal profile in the work piece. Bottle boring tools are developed for specific internal profiles of components. The internal profile is larger than the tool entry and exit diameters. The operation requires the use of CNC controls to program the various coordinates for the required profile.

Pull reaming is used to improve straightness and accuracy of long holes. The reaming tool is rotated and pulled through the drilled hole. The surface finish as well as size of drilled hole is improved using this process. Profimach provides reliable, well designed machines for this process that are guaranteed to perform.

Deep hole drilling

There are three traditional deep hole drilling methods: gundrilling or single lip drill system, BTA or single tube system (STS) and ejector Sytem or double tube system (DTS).

Gun Drilling

Single Lip Drill System

SLS

Ø 2~40 mm

BTA Drilling

Single Tube System

STS

Ø 20~1400 mm

Ejector Drilling

Double Tube System

DTS

Ø 20~500 mm

Gun drilling is the oldest and most widely used method of deep hole drilling employed by industry today. The drill or “gun drill” is generally a one-piece assembly consisting of a hollow cylindrical drill driver. Also, it is brazed to a V-shaped crimped tube and finally assembled to a brazed-on solid carbide drill head. Both the crimped drill shank and the brazed-on carbide drill head from a kidney-shaped cross-section. Whereby the open V-shaped section acts as a chip flute.

In all cases, gun drills require filtered, the high-pressure coolant that is introduced through the center of the crimped gun drill shank. T

24 Video Xxx Het

Naked Big Bodied Women

Feel Her Tits Tumblr

Hentai Free Video Tubes

Dog Fuck Sexy Girl

CNC deep hole drilling machine and gun drilling tools ...

Deep hole machines - Deep hole drilling, gundrilling, BTA ...

Deep Hole Drilling Machines - Precision Gundrilling ...

All Machines | UNISIG Deep Hole Drilling Machines

Deep hole machines, deep hole drilling machines, deep hole ...

Deep Hole Drilling. Precision Deep Hole Drilling Machines

Deep Hole Drilling Machines For Sale From BTA Heller

Used Deep Hole Drilling Machines Machines - GD Machinery ...

Deep Hole Drilling Machines